PDF Download: [CA1228833A1-Gas\_Electrical\_Hydrogen\_Generator.pdf](http://stanslegacy.com/attachments/5)

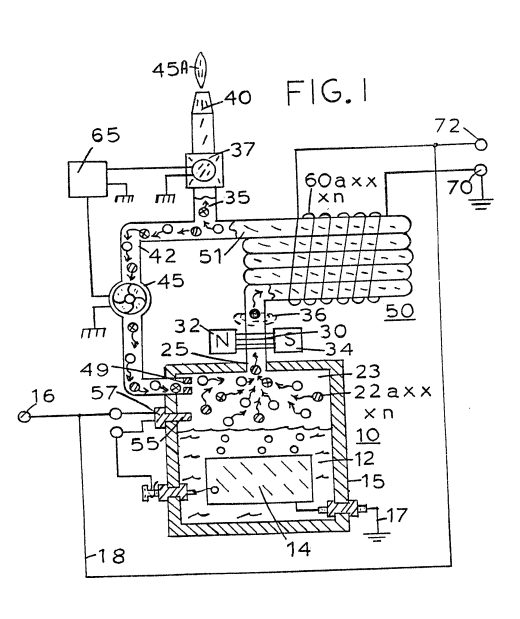

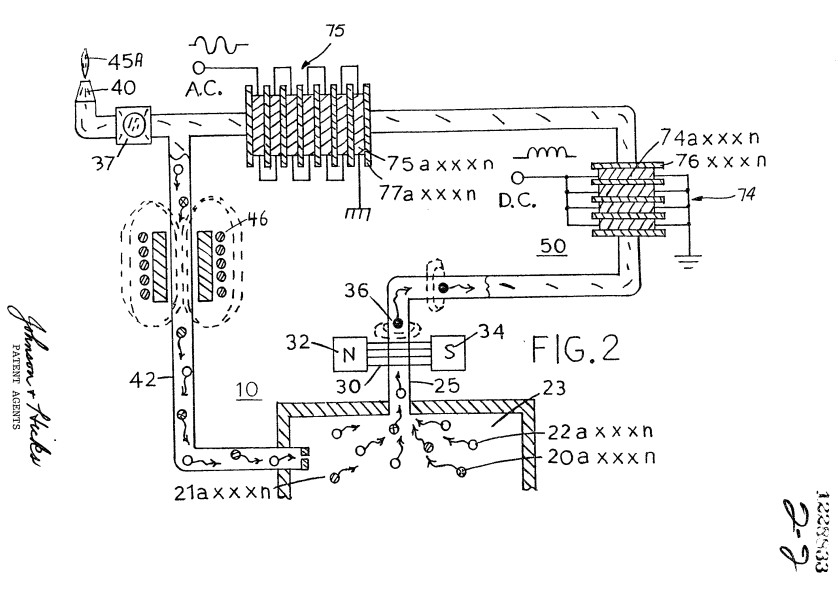

> (51) INT. CL. C25B 1/04 Consumer and Consommation Corporate Affairs Canada et Corporations Canada > (11) (A) No. 1 228 833 > (45) ISSUED 871103 > (52) CLASS 204-152 C.R. CL. 322-1as) ca) CANADIAN PATENT «2 > (54) Gas Electrical Hydrogen Generator > {72) Meyer, Stanley A.,U.S.A. > {21) APPLICATION No. (22) FILED > (30) PRIORITY DATE > DISTRIBUTED BY THE PATENT OFFICE, OTTAWA. CCA-274 {11-82) C-2388 #### Illustrations| [](http://stanslegacy.com/uploads/images/gallery/2022-06/h2snHw4KdVGSi3Ps-screenshot-from-2022-06-23-10-54-04.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/COvSi5xtxP3MLvor-screenshot-from-2022-06-23-10-48-13.png) |

Further, it has been found that the increase in pressure of the gases in chamber 23 increases the velocity of the gas exponentially. Simply, an arithmetical increase in pressure of the gases released results in a geometrical increase in frequency and amplitude of the output voltage from either the direct current winding 74 or the alternating current winding 75.

There will be instances where an increase in velocity (pressure) is needed to increase the output voltage of the electrical generator but the generation of more hydrogen gas may be undesirable. That is, for instance when’the flame 45A is a con- trolled gas mixture flame. The addition of more hydrogen will increase the temperature of the combustibility of the mixture and will increase its velocity. The utility of the flame, if not quenched, will be affected proportionately.Accordingly, to increase the gas pressure in chamber 23 **other non-combustible gasses** 2la xxx n, such as **nitrogen** are added via pressure inlet means to the mixture.

Although certain and specific embodiments are shown and described, alternatives and modifications may be had without departing from the spirit and scope of the invention. ##### THE EMBODIMENTS OF THE INVENTION IN WHICH AN EXCLUSIVE PROPERTY OR PRIVILEGE IS CLAIMED ARE DEFINED AS FOLLOWS: 1\. Apparatus comprising: > a housing having a water reservoir for retaining water therein and a gas collection chamber; > > a pair of similar non-oxidizing exciter elements positioned in said water reservoir and adapted to be connected to a voltage potential that creates a negative charge on one of the exciter elements and a positive charge on the other and thereby release gases including hydrogen and oxygen from water in the reservoir; > > a non-magnetic tubing connected at one end to said collection chamber via an outlet therefrom; > > a magnetic polarizer positioned for magnetically charging gas flowing through said tubing; and an inductive winding positioned over said tubing downstream from said polarizer whereby flux lines of magnetized gas passing through said tubing and traversing said inductive winding induce a current/voltage in said inductive winding. 2\. The apparatus of Claim 1 further comprising: gas utilization means connected to the other end of said tubing for utilizing said generated hydrogen/oxygen gas mixture. 3\. The apparatus of Claim 1 further comprising: > a nozzle connected to the other end of said tubing, > > said nozzle having a port of pre-determined size and configuration through which the gases are expelled, and means for igniting said gases. 4\. The apparatus of Claim 1 further comprising: control means for maintaining a predetermined gas pressure in said collection chamber. 5\. The apparatus of Claim 1 further comprising: > a pressure gauge for determining the pressure in said collection chamber, and > > switch means for controlling the voltage potential source to terminate the generation of hydrogen/oxygen gases upon said collection chamber attaining a predetermined pressure. 6\. The apparatus of Claim 1 further comprising: a gas line tubing connected to the other end of said non-magnetic tubing and to said collection chamber in a closed loop arrangement. 7\. The apparatus of Claim 1 further comprising: a gas line tubing connecting the other end of said non-magnetic tubing to said collection chamber in a closed loop arrangement, and means in said gas line tubing for maintaining said polarized hydrogen and oxygen atoms circulating through said non-magnetic tubing. 8\. The apparatus of Claim 1 further comprising: a gas line tubing connected to the other end of said non-magnetic tubing *and* to said collection chamber in a closed loop arrangement, and a unidirectional valve connected to the end of said gas line tubing connected to said collection chamber. 9\. The apparatus of Claim 1 further comprising: a gas line tubing and gas utilization means, a Y-type connector for alternately connecting said gas line tubing to said gas utilization means and said collection chamber in a closed loop arrangement. 10\. The apparatus of Claim 1 further comprising: a gas line tubing and gas utilization means, a Y-type connector for alternately connecting said gas line tubing to said gas utilization means said collection chamber in a closed loop arrangement, two directional valve means, and a demand circuit connected to said valve means for selectively connecting said gas line tubing to said gas utilization means or said collection chamber in response to pre-determined conditions. ll. An apparatus comprising: a gas generator housing having a gas collection chamber for maintaining a preset volume of gas therein under pressure, outlet means from said gas collection chamber, a non-magnetic tubing connected to said outlet means, a magnetic polarizer positioned adjacent said outlet means between said chamber and said tubing for magnetically charging gas expelled from said chamber through said outlet means, and an inductive coil positioned over said non-magnetic tubing whereby the flux lines of magnetized gas passing through said tubing and traversing said inductive coil, induce a current/voltage therein. 12\. The apparatus of Claim 11 wherein: said gas is a combustible gas, and utilization means connected to the opposite end of said non-magnetic tubing for utilizing said gases. 13\. The apparatus of Claim 11 wherein: said coil comprises a plurality of windings wound in parallel, and wherein said induced voltage/current therein is of a single polarity. 14\. The apparatus of Claim 11 wherein: > said coil comprises a plurality of windings connected in series polarity. 15\. The apparatus of Claim 11 wherein: > said coil comprises a plurality of windings and wherein the number of said plurality of windings is determinative of the frequency of the said induced voltage/current therein. 16\. The apparatus of Claim 11 further comprising: means for varying the pressure of said gas in said collection chamber to vary the output frequency of said induced voltage in said coils. 17\. The apparatus of Claim 11 further comprising: means for varying the generation of said gas to vary the pressure of said gas in said collection chamber to vary the output frequency of said induced voltage in said coils. 18\. The apparatus of Claim 11 further comprising: > means for adding non-combustible gases to said collection chamber to vary the pressure of said gas in said collection chamber to vary the output frequency of said induced voltage in said coils. 19\. The apparatus of Claim 11 wherein: > said non-magnetic tubing further comprises means connected thereto for returning said magnetized gas to said collection chamber, and means for recirculating said gas through said chamber, said non-magnetic tubing and said last named means. 20\. The apparatus of Claim 11 wherein: > said non-magnetic tubing further comprises means connected thereto for returning said magnetized gas to said collection chamber, a particle accelerator for recirculating said gas through said chamber, said tubing, and said last named means. 21\. Apparatus comprising: > a closed vessel suitable for maintaining a volume of water therein, and permitting the addition of water thereto; > > a pair of electrically conductive exciter elements formed of a same non-reactive material located in said vessel in a predetermined spatial relationship to one another and adapted to be connected to a source of a voltage potential that creates a potential difference between an arbitrary electrical ground and the source output with one of said exciter elements being connected to said arbitrary electrical ground and the other of said exciter. elements being connected to said source output, whereby there is formed a nominally positive electrical voltage zone in water adjacent said exciter element connected to said output and a nominally negative voltage zone in water adjacent said exciter element connected to said electrical ground as the voltage potential is applied thereto to a degree such that the hydrogen atoms and the oxygen atoms disassociate from water molecules in the vessel and are released in the form of a gas mixture; > > a gas collection chamber for maintaining a volume of said gas released from water when in the vessel and a potential difference is applied to said exciter elements; > > a non-magnetic tubing connected at an outlet from said collection chamber; > > a magnetic polarizer positioned adjacent the end of said tubing as the gas is expelled from said outlet; and an inductive winding positioned over said tubing wherein flux lines of the magnetized gas passing through said tubing, traverse said inductive winding and induce a current in said inductive winding. # CA1235669A1 Controlled Hydrogen Gas Flame**PDF Download:** [SMeyer-CA1235669A1-Controlled\_Hydrogen\_Gas\_Flame.pdf](http://stanslegacy.com/attachments/9)

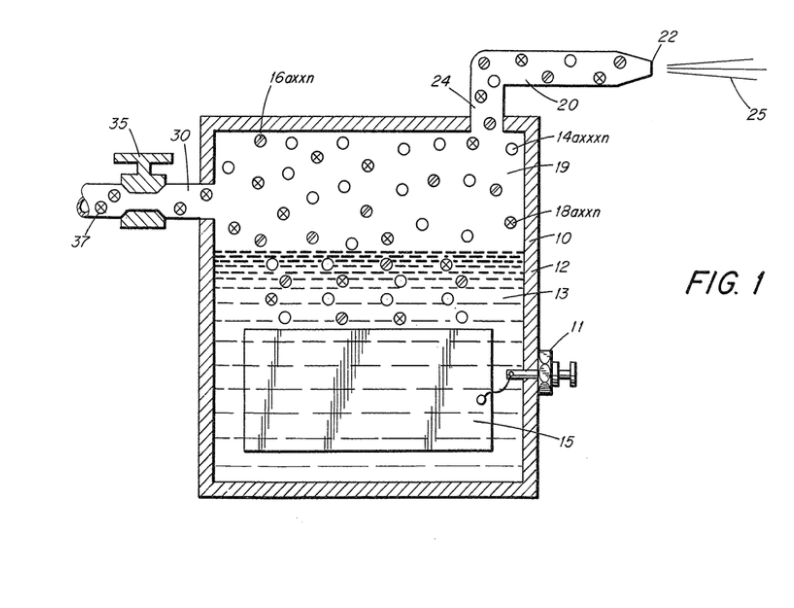

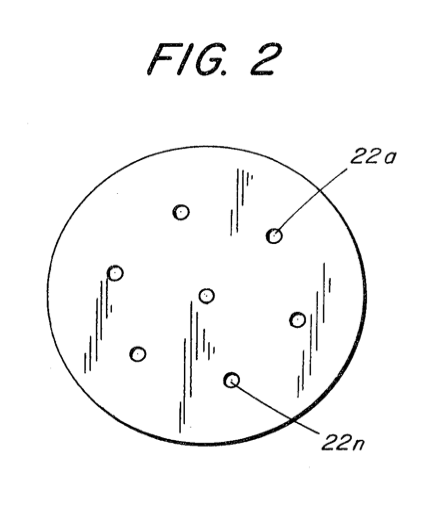

> Consumer and Consornmation aS Corporate Affairs Canada el Corporations Canada > > (11) (A) No. 1 235 669 > (45) ISSUED 880426 > (52) CLASS 204-78 C.R. CL. 204-1664 > (51) INT. CL. c25B 1/04us ca GANADIAN PATENT «2 > (54) Controlled Hydrogen Gas Flame > (72) Meyer, Stanley A.,U.S.A. > (21) APPLICATION No. 420,890 > (22) FILED 830204 > (30) PRIORITY DATE U.S.A. (411,977) 820825 No. OF CLAIMS 9 > > Canada > DISTRIBUTED BY THE PATENT OFFICE, OTTAWA, CCA-274 (11-82) VX #### Illustrations| [](http://stanslegacy.com/uploads/images/gallery/2022-06/C8dIULi2BKjwu6wY-image-1656375633551-20-31.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/yM1i607PuVo5cauB-image-1656375620401-20-17.png) |

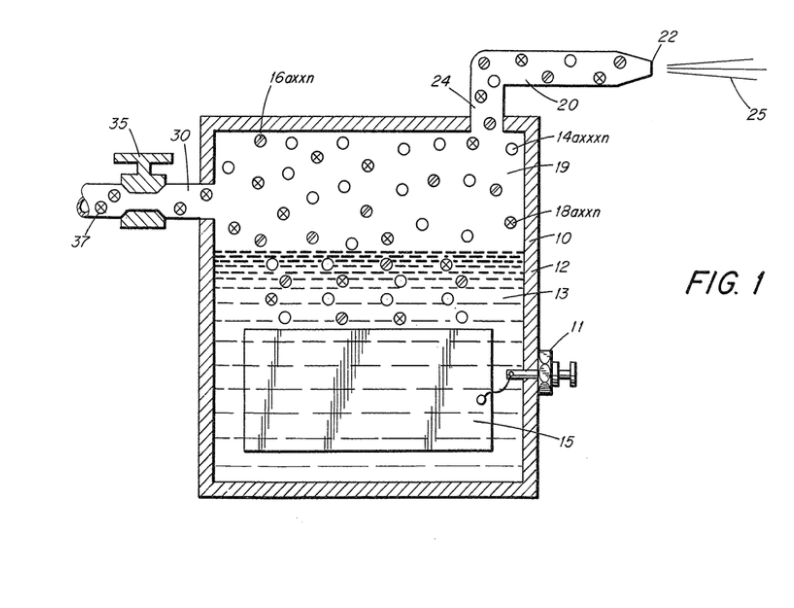

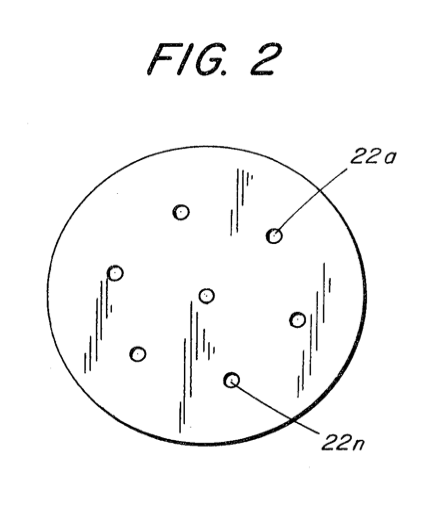

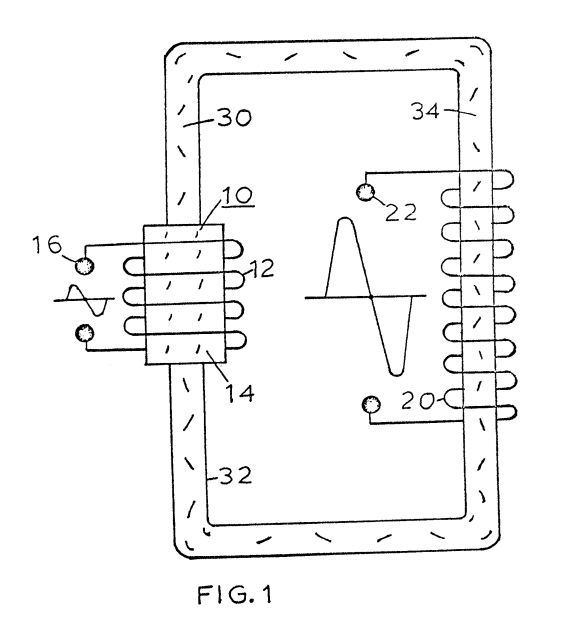

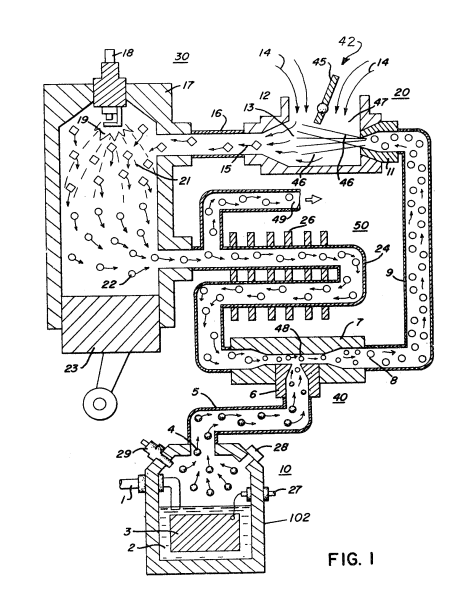

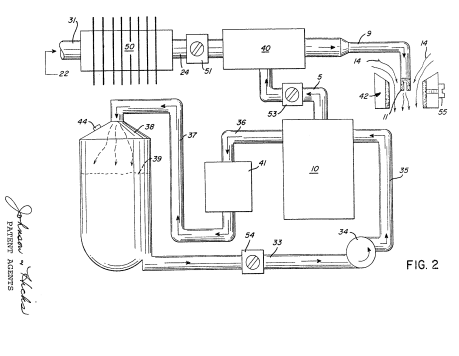

This invention relates to apparatus for generating gases from water and for the controlled burning of such generated gases.

The present invention utilizes the hydrogen/oxygen generator disclosed and claimed in my co-pending Canadian Patent Application Serial No. 420,908 filed 4 February, 1983 and entitled "**HYDROGEN GENERATOR SYSTEM**".

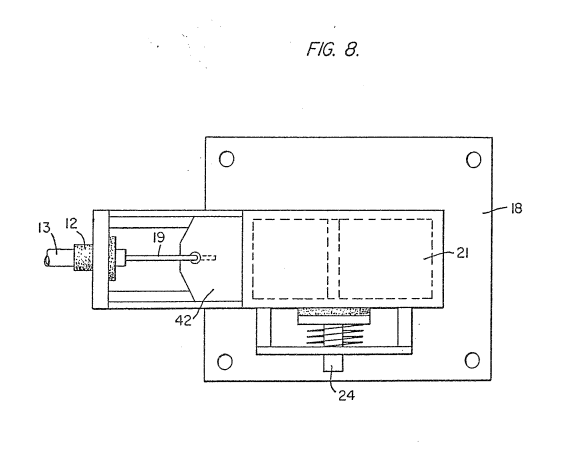

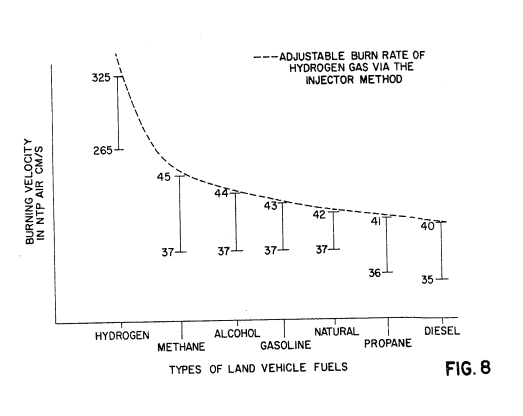

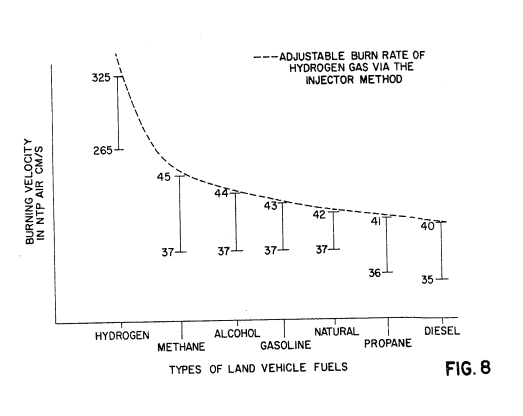

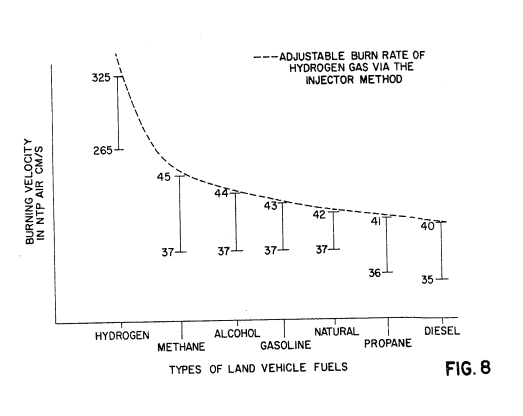

In the process disclosed in said application for separating hydrogen and oxygen atoms from water having impurities, water is passed between two plates of similar non-oxidizing metal. No electrolyte is added to the water. The one plate has placed thereon a positive potential and the other a negative potential from a very low amperage direct— current power source. The action of the direct current voltage on the non-electrolytic water causes the hydrogen and oxygen atoms to be separated and also released are other gases entrapped in the water such as nitrogen. Contaminants in the water that are not released as gases are forced to separate from the water and may be collected or utilized and disposed of in a Known manner. Direct current acts as a static force on the water molecules and a non-regulated rippling direct current acts as a dynamic force. Pulsating the direct current further enhances the release of the hydrogen and oxygen atoms from the water molecules, The electrolysis process for generating hydrogen and oxygen gas from water is well known in the art. It is, of course, further understood with a proper mixture of oxygen gas, the hydrogen gas is combustible and under ideal conditions a flame, may be had. Reference is made to U.S. Patent 4,184,921. However, in that the burning velocity of hydrogen is so great (265-325 cm./sec. versus 37-45 cm./sec. for gasoline) the hydrogen ensuing from a nozzle will not under ordinary circumstances sustain a flame.Therefore, to sustain a flame at a nozzle attached to a hydrogen generator the burning velocity of the hydrogen gas must be reduced.

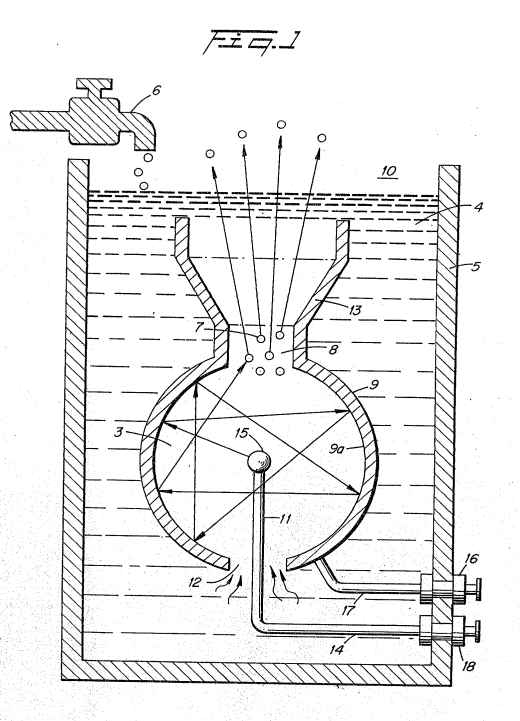

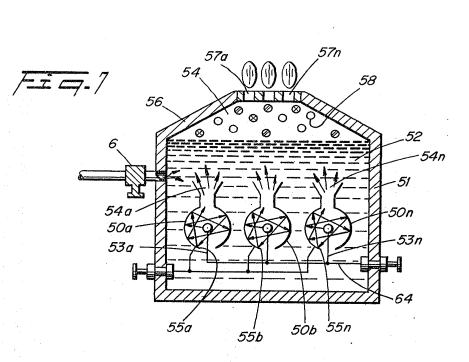

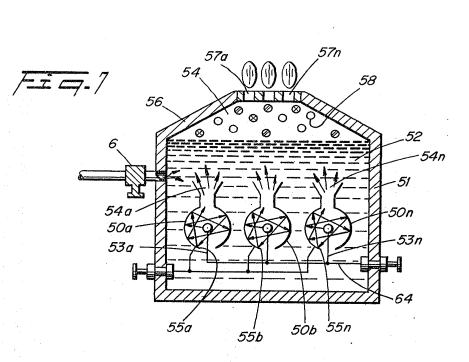

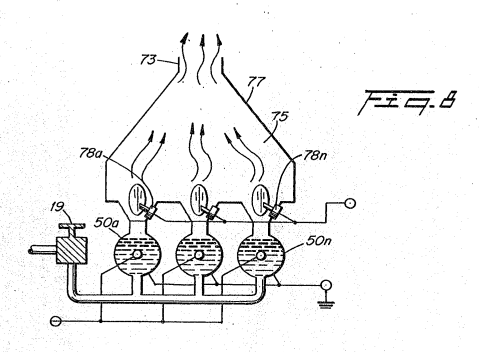

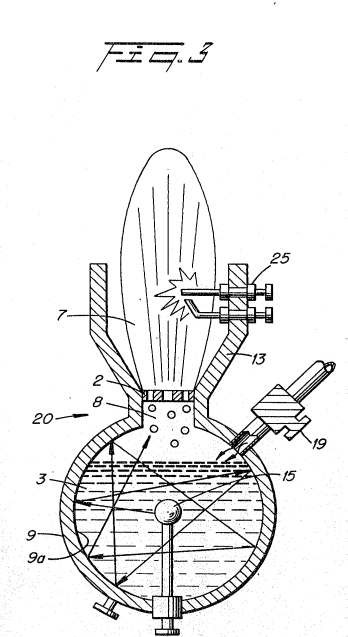

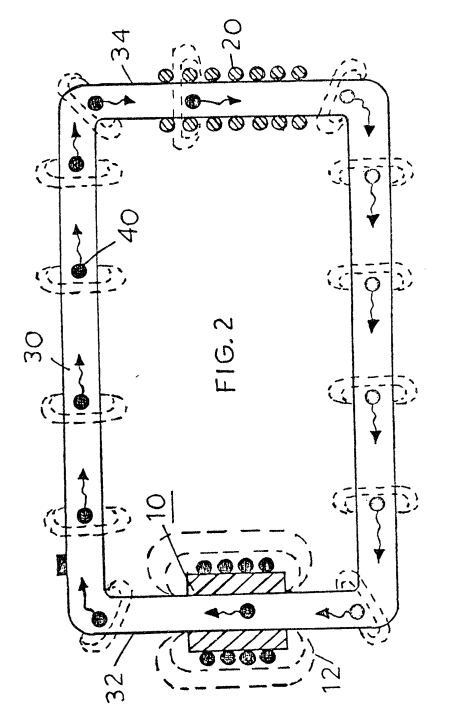

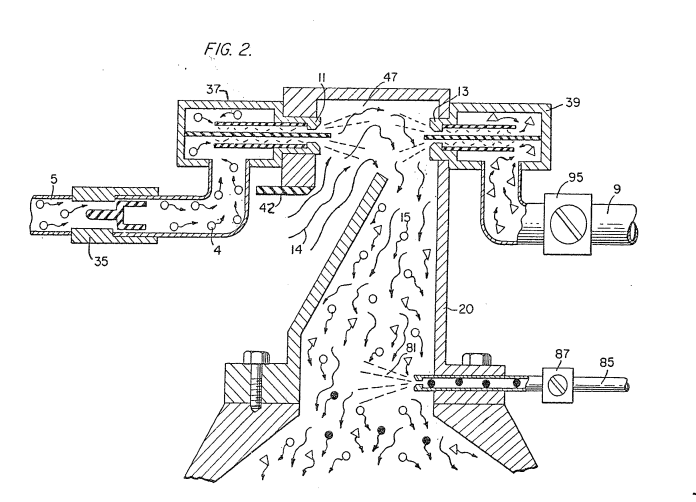

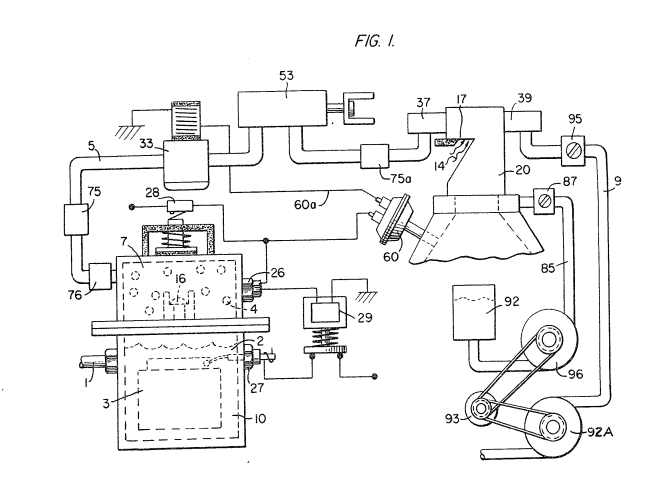

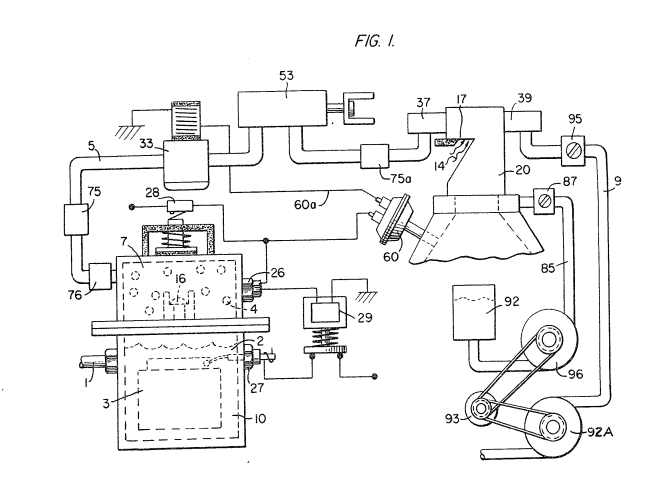

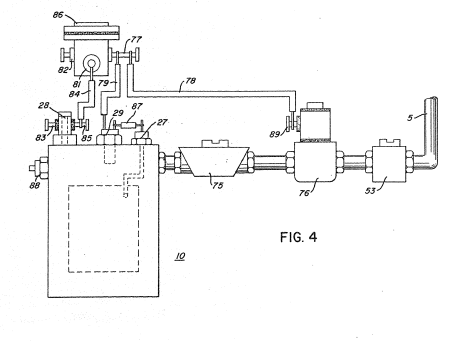

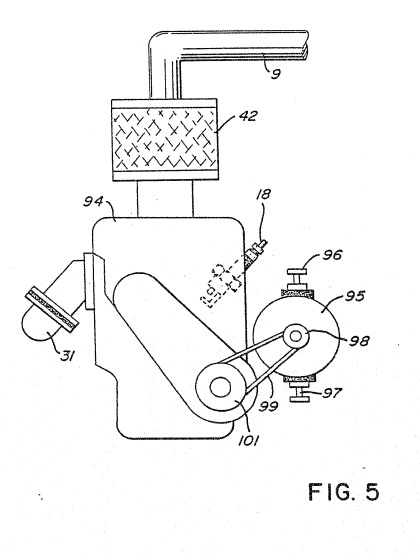

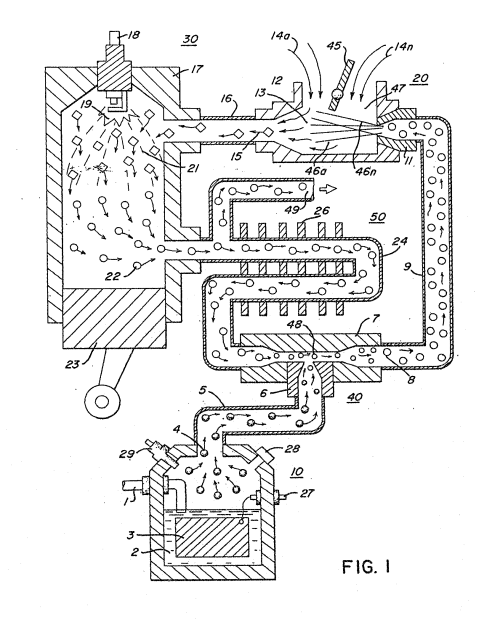

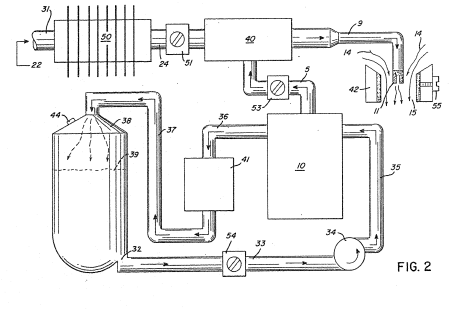

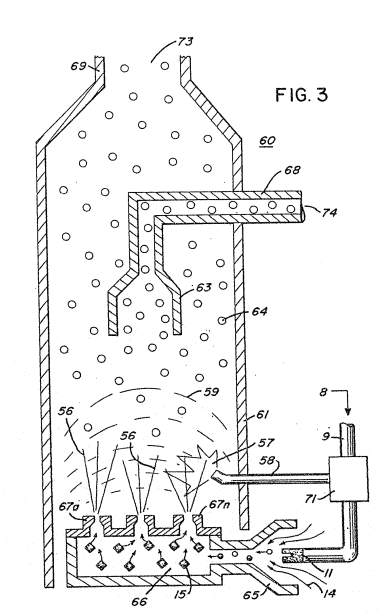

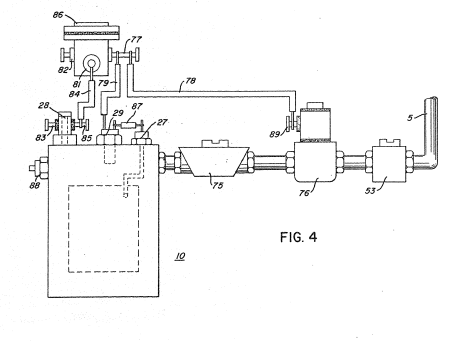

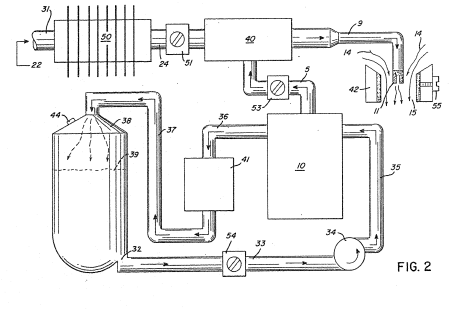

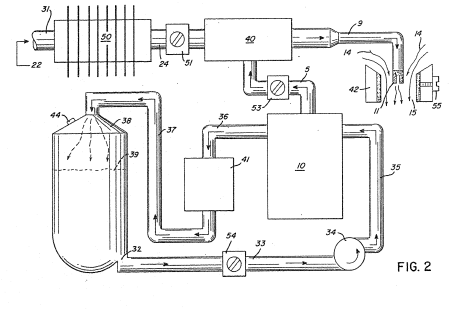

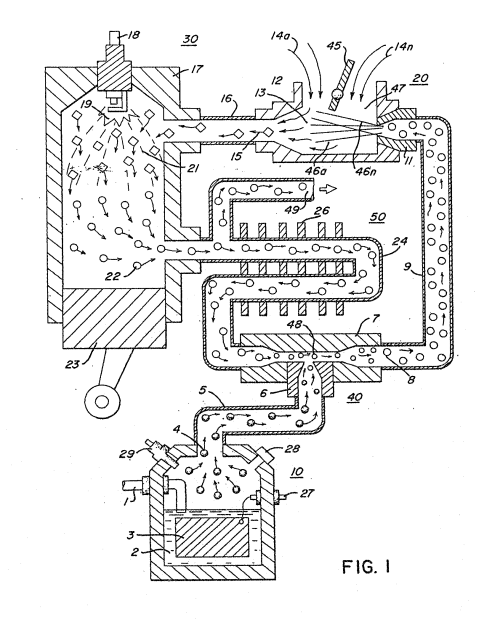

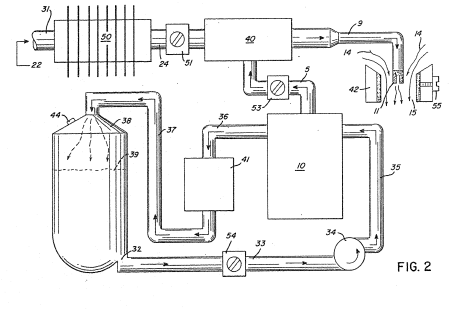

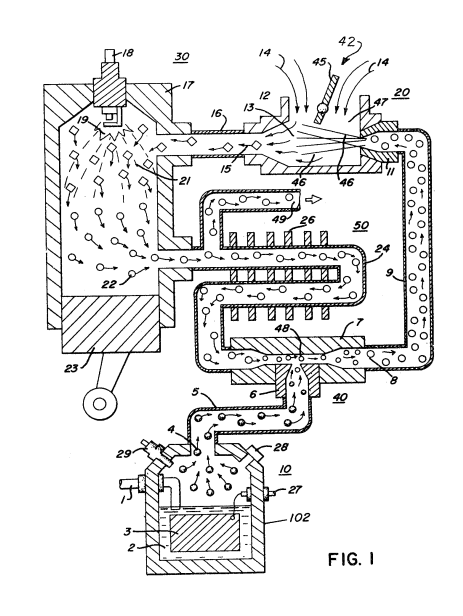

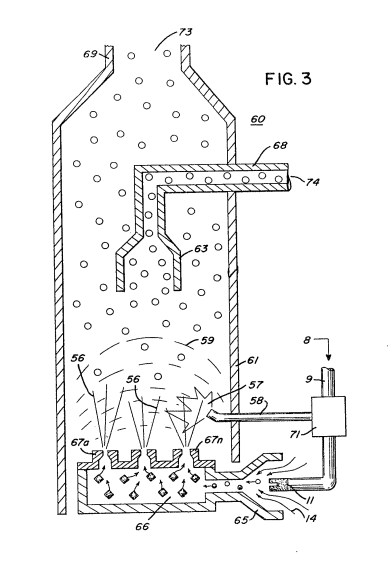

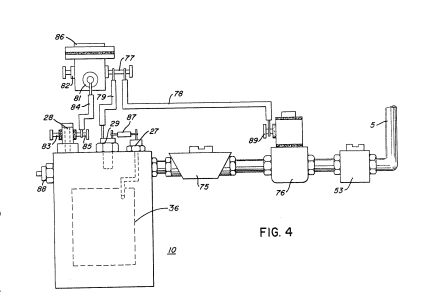

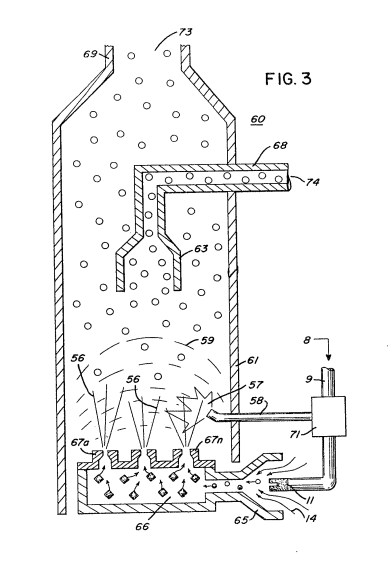

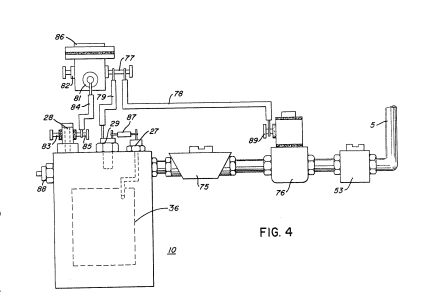

It has been found that all water in its natural state whether it be tap water, well water, sea water, or fresh water is a saturate of ambient air. Further, in that ambient air contains a substantial amount of nitrogen, all natural water will have entrapped therein nitrogen. Again, the percentage of nitrogen entrapped in natural water has been determined to be a fixed percentage and very uniform irrespective of the source of the water or its impurities. A principal object of the present invention is to provide a new and improved hydrogen/oxygen generator that is operable from a water source that provides hydrogen/oxygen output that will have a sustained burn. Another object of the present invention is to provide a hydrogen/oxygen generator that in addition to the hydrogen and oxygen gases releases non-combustible nitrogen gas capable of reducing the burning velocity and temperature of a pure hydrogen/oxygen flame. A further object of the present invention is to provide a hydrogen generator that includes the controlled addition of other non-combustible gases to the gas chamber thereof to thereby further control the burning velocity and temperature of the hydrogen gas. In accordance with the present invention a nozzle is connected to a gas collection chamber via an appropriate line and has a port opening of a controlled size and configuration, related to the size of the flame and the temperature and velocity of the burning gas mixture. To maintain the flame, i.e. prevent blowout, additional nozzles are included when the overall flame size is to be increased. More particularly there is provided in accordance with the present invention an apparatus for generating gases from water and for the controlled burning of the gases generated thereby comprising: > a housing having a chamber for containing natural water therein including entrapped non-combustible gases; > > a pair of similar non-oxidizing electrodes in said chamber and adapted to be connected to a source of rippling wave form direct current voltage in which the current flow is restricted to provide a force action on water in said chamber, which liberates the hydrogen atoms and oxygen atoms from said water as well as non-combustible gases dissolved in said water and thereby producing a mixture of hydrogen, oxygen and non— combustible gases; > > a gas collection chamber in said housing for collecting and intermixing said released gases; and > > a nozzle attached to the gas collection chamber of said housing including an inlet for receiving said mixture of hydrogen, oxygen and non-combustible gases; > > said nozzle having a port of predetermined size and configuration for expelling said mixed gases at a rate so as to sustain a flame from the gases that are liberated from the water. #### Description Of Drawings: The invention is illustrated by way of example in the accompanying drawings wherein: Figure 1 is a cross-sectional view of a hydrogen generator illustrating the features of the present invention in. its most preferred embodiment incorporated therein; and [](http://stanslegacy.com/uploads/images/gallery/2022-06/C8dIULi2BKjwu6wY-image-1656375633551-20-31.png) Figure 2 is a front face view of a nozzle having increased number of nozzle ports to increase the flame size. [](http://stanslegacy.com/uploads/images/gallery/2022-06/yM1i607PuVo5cauB-image-1656375620401-20-17.png) Referring to the drawings the hydrogen generator 10 is the subject of my aforementioned co-pending application Serial No. 420,908. The generator 10 comprises a closed watertight housing 12 having a quantity of natural water 13 in the bottom thereof. Submerged in the water 13 is a pair of plates 15 (one not shown) which have a direct current low amperage voltage, applied thereto via connector 11 during operation. As get forth in my co-pending patent application supra, the electrical potential applied to the similar non-oxidizing metal plates is a sub-atomic action. In this way the hydrogen atoms 14 a xxx n and the oxygen atoms 18 a xxx n are released from the water molecule. Unlike the electrolysis process for generating hydrogen from distilled water, the hydrogen generator of my aforementioned patent application, utilizes water 13 that need not be pure --~ simply any water irrespective of contaminants and source. Natural water such as tap, well, sea, or fresh water is an absorber of ambient air and since ambient air contains a substantial amount of nitrogen gas so does the natural water with the ambient air absorbed therein. In operation of the hydrogen generator, the gases released from natural water are thus nitrogen, hydrogen and oxygen. In the preferred embodiment utilizing tap water, the nitrogen gasses 16 a xxx n are intermixed with the hydrogen gases 14 a xxx n and the oxygen gases 18 a xxx n in the chamber 19 of the hydrogen generator 10. Upon release of the gases via line 24 and nozzle 20 and then port 22 the gas mixture is ignited to provide flame 25. The flame 25 is sustained in that the nitrogen gases 16 a xxx n reduces the burning velocity and temperature of the hydrogen gas 14 a Xxx Nn. A realistic and practical manner of further controlling the burning velocity and temperature of the hydrogen gases 14 a xxx n, is by adding non-combustible gases directly to the hydrogen and oxygen gases generated. This is accomplished by inlet 30 to the upper gas chamber 19 of the hydrogen generator. Valve means 35 is adjustable to control the amount of non- combustible gases 37, added to the gas chamber 19. The nozzle 20 connected to the chamber 19 of the generator 10 via line 17, is of a given configuration to permit a predetermined quantity of gases to be expelled from the port 22. The port size is dependent on the gases generated, and collected in the chamber 19, the pressure of the chamber 19 of the generator 10, and the size of the flame desired. To increase the size of the flame 25 would appear to be a simple matter of increasing the rate of gases generated. However, an increase of gases merely causes a blowout at the port or opening 22 of the nozzle 20. This flame blowout will occur since an increase in hydrogen gas generation disrupts the ratio of the initial mixture even though the percentages remain constant. Typically, tap water contains known percentages of hydrogen, oxygen, and nitrogen. The percentages vary somewhat dependent on the other gases that may be trapped in the tap water. The increase in production will not affect the percentages but it must be appreciated that the volume of the gases will be proportionately increased. In turn, the volume being directly related to pressure, the pressure will be similarly increased. [](http://stanslegacy.com/uploads/images/gallery/2022-06/yM1i607PuVo5cauB-image-1656375620401-20-17.png)To effectively reduce or counteract the velocity due to the increased pressure of the hydrogen gas mixture in the chamber 19 a large port 22 would appear to be capable of handling the increased pressure, but as aforesaid, a larger port with a high velocity hydrogen gas mixture will cause a flame blowout. To sustain a larger flame with increased pressure, additional nozzles having ports 22 **a xxx n** or, a nozzle 20 with multiple ports **22 a xxx** n as shown in Figure 2, can be used. The larger the desired flame the greater will be the number of ports required. It can be understood that a port that will not 5 sustain a flame does present a safety factor relative to hydrogen spark back to the chamber 19. Hence, controlling the size of the port 22 in effect provides a quencher of hydrogen spark back.Although certain and specific embodiments are shown and described it is within the scope and spirit of the present invention to include alternatives and modifications thereto.

##### THE EMBODIMENTS OF THE INVENTION IN WHICH AN EXCLUSIVE PROPERTY OR PRIVILEGE IS CLAIMED ARE DEFINED AS FOLLOWS: 1\. An apparatus for generating gases from water and for the controlled burning of the gases generated thereby comprising: > a housing having a chamber for containing natural water therein including entrapped non-combustible gasses; > > a pair of similar non-oxidizing electrodes in said chamber and adapted to be connected to a source of rippling wave form direct current voltage in which the current Flow is restricted to provide a force action on water in said chamber, which liberates the hydrogen atoms and oxygen atoms from said water as well as non-combustible gases dissolved in said water and thereby producing a mixture of hydrogen, oxygen and non-combustible gases; > > a gas collection chamber in said housing for collecting and intermixing said released gases; and > > a nozzle attached to the gas collection chamber of said housing including an inlet for receiving said mixture of hydrogen, oxygen and non-combustible gases; > > said nozzle having a port of predetermined size and configuration for expelling said mixed gases at a rate so as to sustain a flame from the gases that are liberated from the water. > > 2\. The apparatus of Claim 1 including means for separately introducing non-combustible gases to said gas collection chamber. 3\. The apparatus of Claim 2 including valve means for controlling the amount of non-combustible gases introduced into said chamber. 4\. The apparatus of Claim 1 wherein said nozzle has a plurality of separate ports to thereby control the flame. 5\. A method of producing a combustible gaseous mixture and sustaining controlled burning thereof comprising: (a) providing a quantity of water in a water holding chamber having a pair of similar non-oxidizing electrodes therein; (b) applying a rippling wave form electric potential across said electrodes without any change of polarity and limiting the current flow so as to liberate hydrogen atoms and oxygen atoms from the water molecules as well as non-combustible gases dissolved in the water and thereby provide combustible and non-combustible gases; (c) collecting and intermixing said gases; and (ad) providing a nozzle having at least one port of predetermined size and configuration such that the gaseous mixture flows therethrough at a rate so as to sustain a flame. 6\. The method of Claim 5 including the step of burning said gaseous mixture at said nozzle port. 7\. The method of Claims 5 or 6 including the step of adding further non-combustible gases to said intermixed gases to provide a combustible gas mixture with a selected burn rate. 8\. The method of Claim 7 including the step of burning said gaseous mixture at said nozzle port. 9\. The method of Claims 7 or 8 including the step of adding further non-combustible gases to said intermixed gases to provide a combustible gas mixture with a selected burn rate. # CA2067735A1 Water Fuel Injection System**PDF Download**: [SMeyer-CA2067735A1-Water\_Fuel\_Injection\_System.pdf](http://stanslegacy.com/attachments/10)

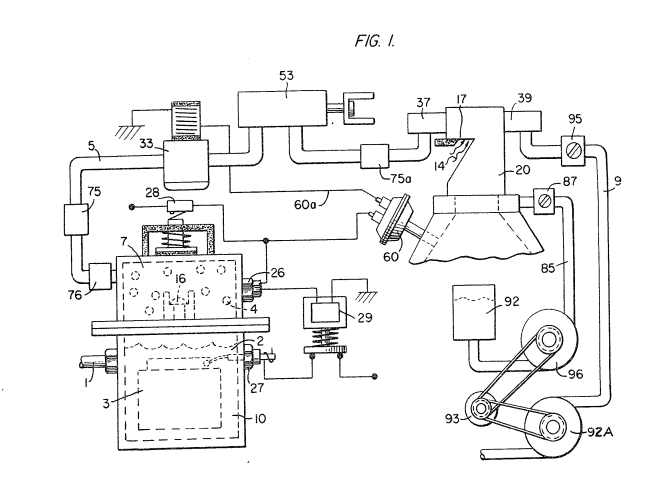

> Consommation et Corporations Canada > > Bureau des brevets Ottawa, Canada K1A 0C9 > > Consumer and Corporate Affairs Canada > > Patent Office > (21) (Al) 2,067,735 > (22) 1991/05/17 > (43) 1992/11/185 > (51) INTL.CL. CO1B~-003/04 > (19) (cA) APPLICATION FOR CANADIAN PATENT (12) > (54) Water Fuel Injection System > (72) Meyer, Stanely A. - U.S.A. j; > (73) Same as inventor > (57) 13 Claims > > Notice: The specification contained herein as filed 78/e‘Geo’s CCA 3254 (10-89) 41 2067735 ### ABSTRACT An injector system comprising an -improved method and apparatus useful in the production of a hydrogen containing fuel gas from water in a process in which the dielectric property of water and/or a mixture of water and other components determines a resonant condition that produces a breakdown of the atomic bonding of atoms in the water molecule. The injector delivers a mixture of water mist, ionized gases and non-combustible gas to a zone or locus within which the breakdown process leading to the release of elemental hydrogen from the water molecules occurs. ##### ##### Illustrations| [](http://stanslegacy.com/uploads/images/gallery/2022-06/BPxw6tWgQ4t6K4fE-screenshot-from-2022-06-25-16-06-25.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/jbbljOtNrspzQXLs-screenshot-from-2022-06-25-16-06-31.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/HCagrcMh2x9XfZlk-screenshot-from-2022-06-25-16-07-16.png) |

| [](http://stanslegacy.com/uploads/images/gallery/2022-06/BKlT18F8VbG4FkpB-screenshot-from-2022-06-25-16-07-47.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/Xobr5XjZEJA3p3K0-screenshot-from-2022-06-25-16-06-42.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/gI1VIukimfS7SEY0-screenshot-from-2022-06-25-16-07-31.png) |

| [](http://stanslegacy.com/uploads/images/gallery/2022-06/ulELezEpAcX50YUX-screenshot-from-2022-06-25-16-07-35.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/WKpYOR7WsjR4QmZF-screenshot-from-2022-06-25-16-06-47.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/HCLF86fMdQMuxbsA-screenshot-from-2022-06-25-16-06-53.png) |

| [](http://stanslegacy.com/uploads/images/gallery/2022-06/jbbljOtNrspzQXLs-screenshot-from-2022-06-25-16-06-31.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/HCagrcMh2x9XfZlk-screenshot-from-2022-06-25-16-07-16.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/BKlT18F8VbG4FkpB-screenshot-from-2022-06-25-16-07-47.png) |

| [](http://stanslegacy.com/uploads/images/gallery/2022-06/gI1VIukimfS7SEY0-screenshot-from-2022-06-25-16-07-31.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/Xobr5XjZEJA3p3K0-screenshot-from-2022-06-25-16-06-42.png) |

Pressure is an **important factor** in the maintenance of the reaction condition and causes the water mist/gas mixture to become intimately mixed, compressed, and destabilized to produce combustion when activated under resonance conditions of ignition.

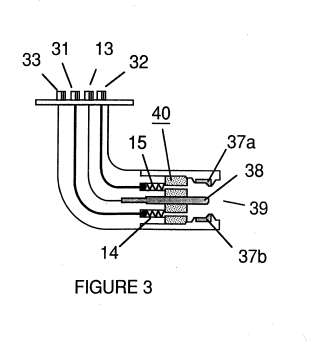

In accordance with the aforementioned conversion process of my patent and application, when water is subjected to a resonance condition water molecules expand and distend; electrons are ejected from the water molecule and absorbed by ionized gases; and the water molecule, thus destabilized, breaks down into its elemental components of hydrogen (2H) and oxygen (0) in the combustion zone. The hydrogen atoms released from the molecule provide the fuel source in the mixture for combustion with oxygen. The present invention is an application of that process and is outlined in Table I: ##### TABLE I **[](http://stanslegacy.com/uploads/images/gallery/2022-06/sBgjYBvthexRrAii-screenshot-from-2022-06-25-16-16-27.png)****Image Text:** Injector Mixture + Pr ndition = Thermal Energy (1) Water Mist (1) Release Under (1) Heat pressure into and Combustion Zone or and (2) Internal . : Combustion (2) Ionized Gas (2) Resonance utilizing Engine the dielectric (Explosive property of water force) as a capacitor and or and . (3) Jet Engine (3) Non-Combustible (3) Unipolar pulsing . Gas at high voltage or (4) Other application

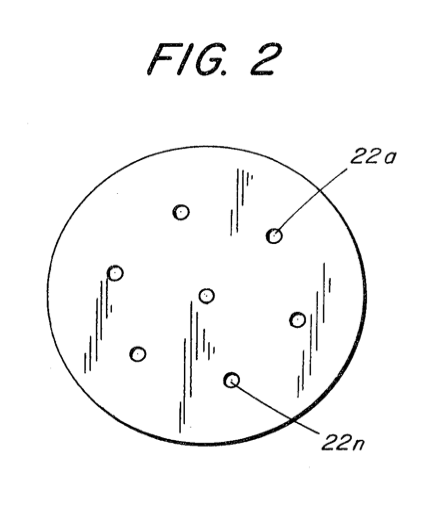

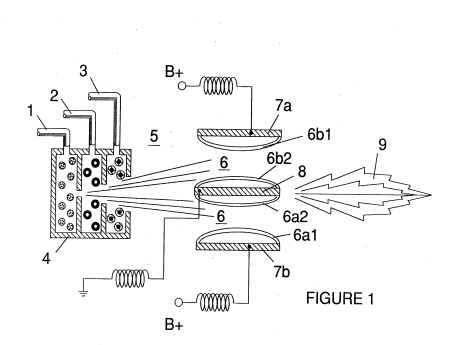

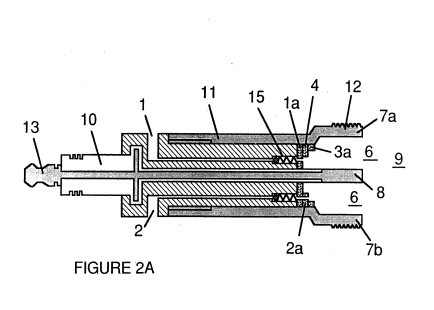

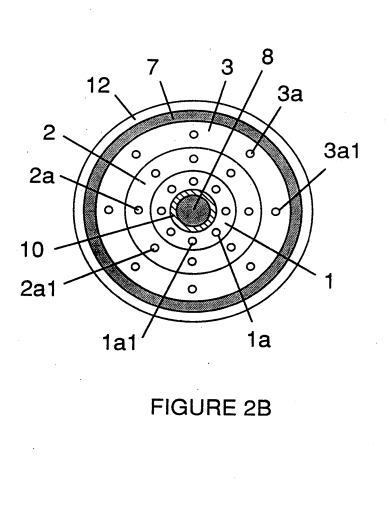

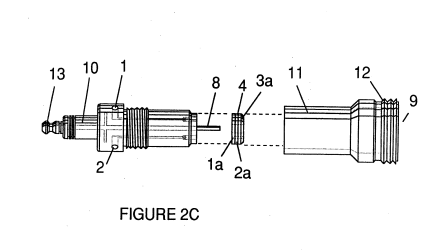

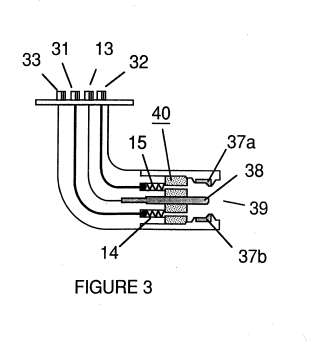

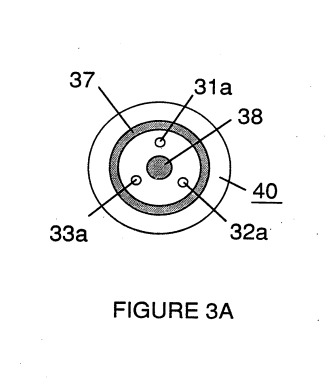

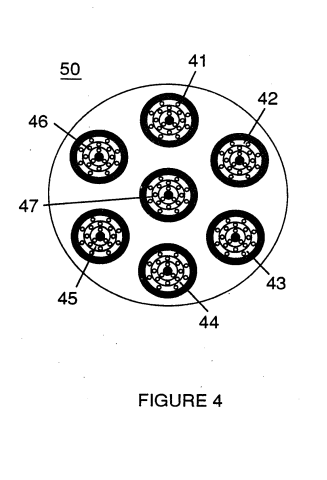

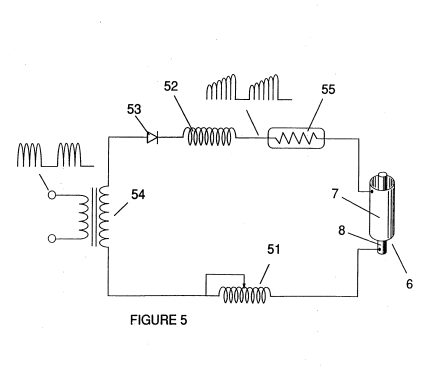

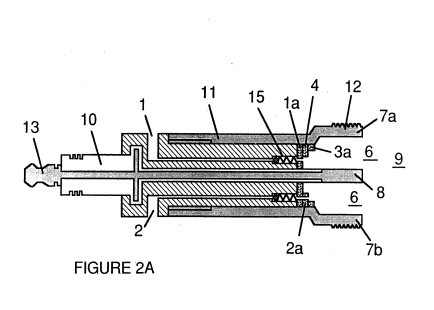

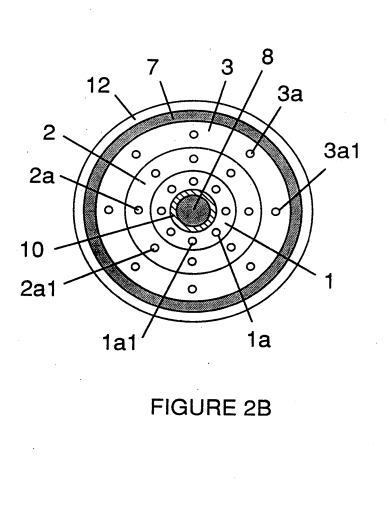

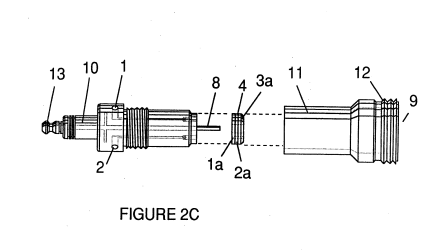

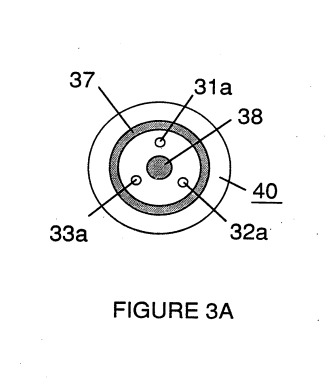

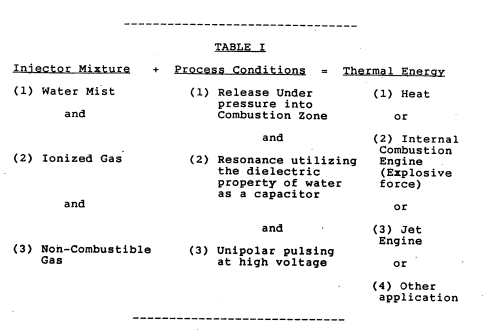

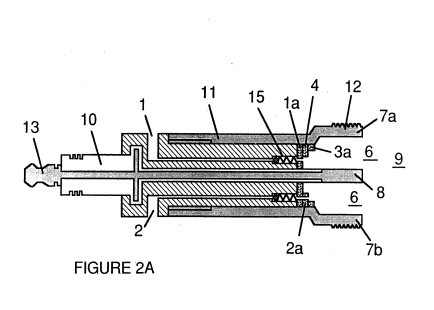

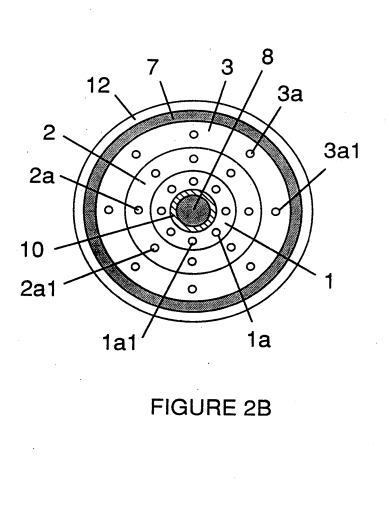

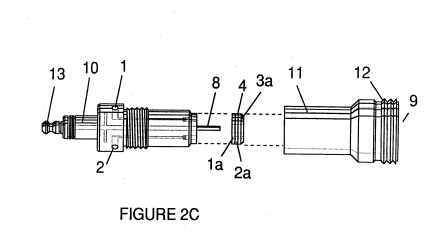

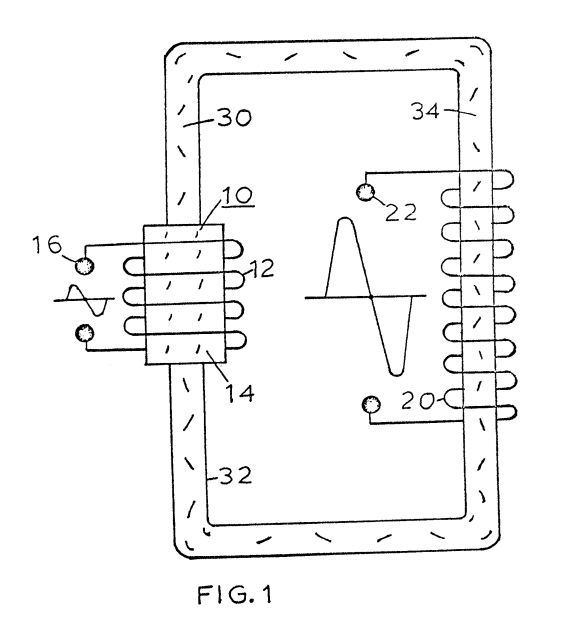

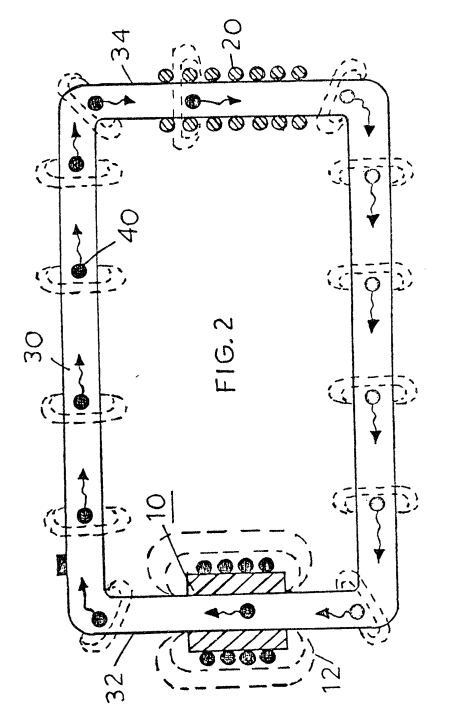

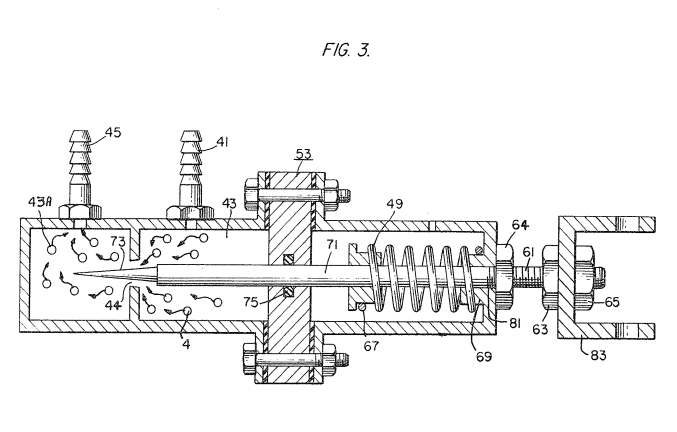

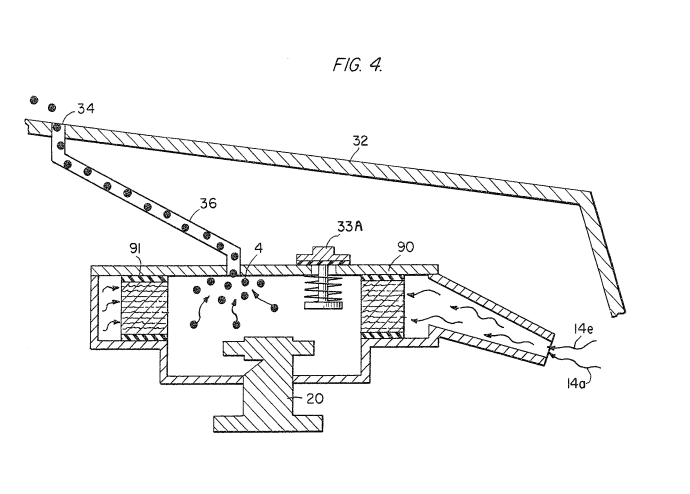

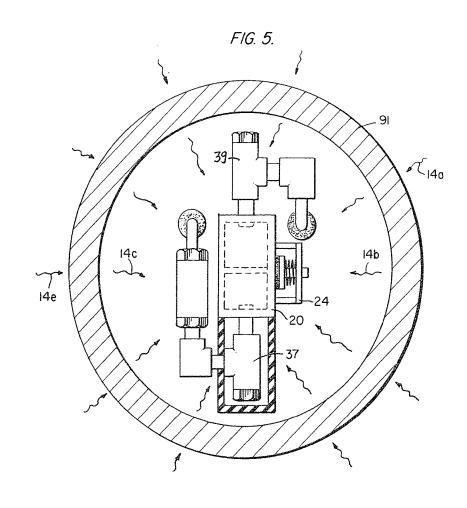

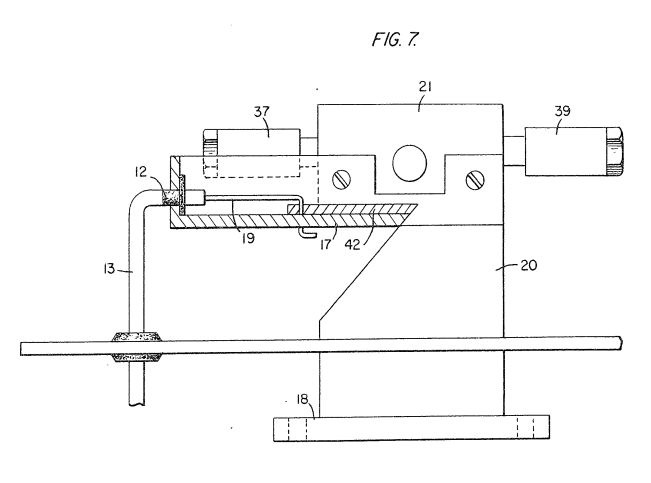

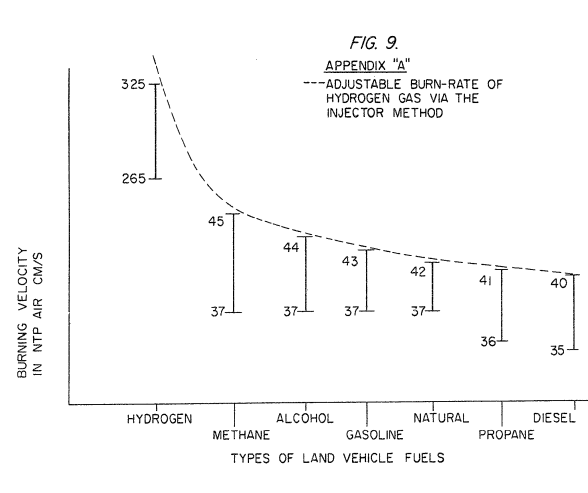

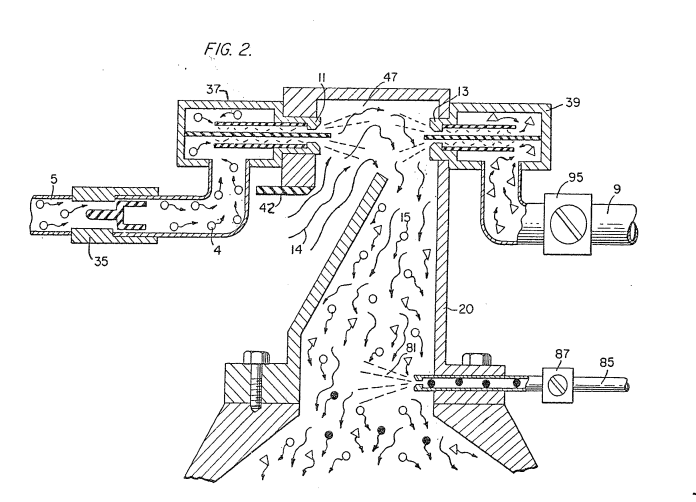

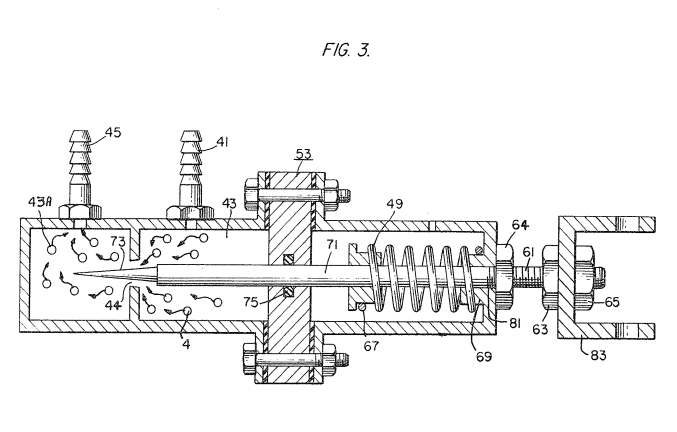

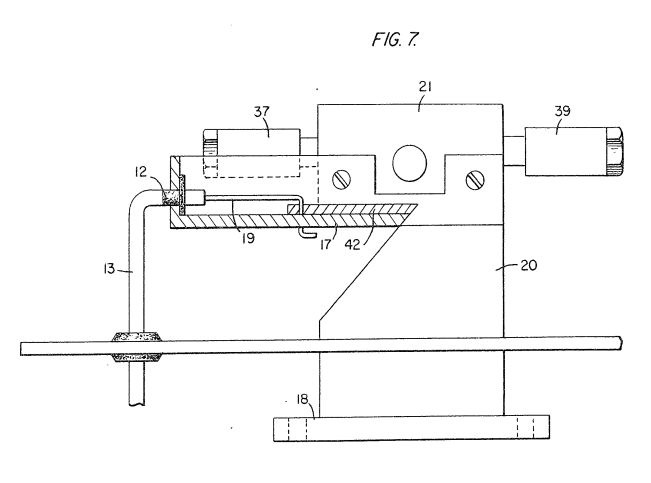

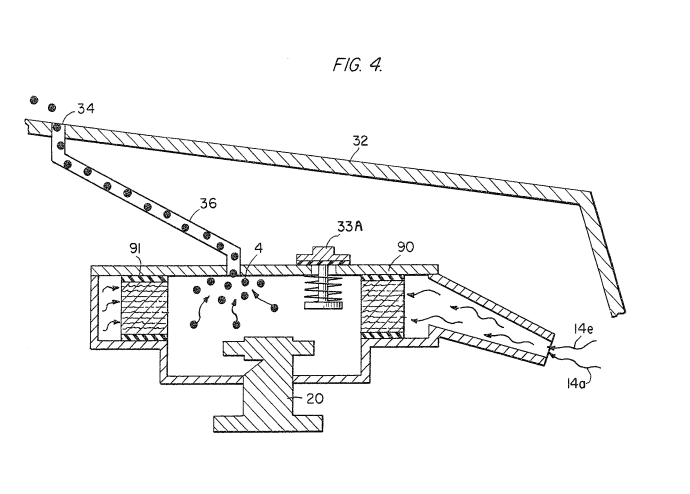

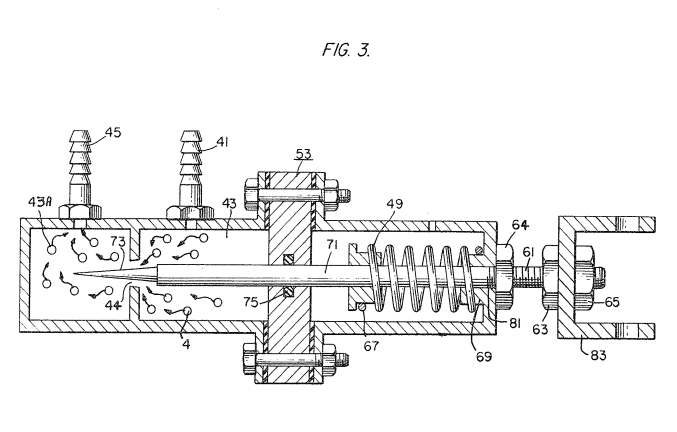

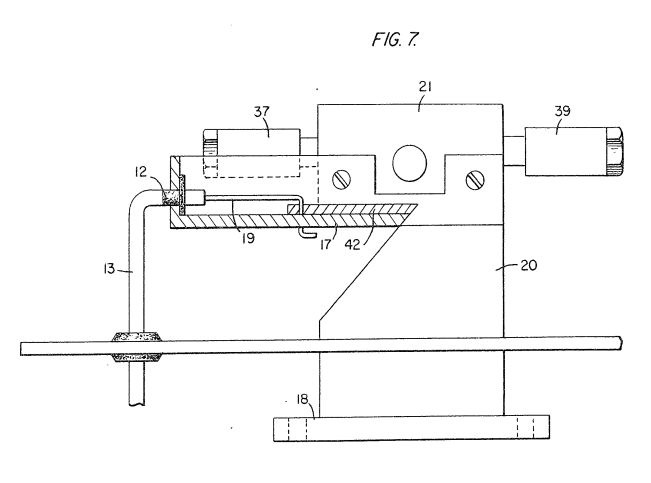

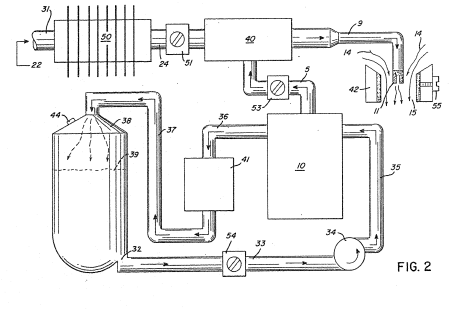

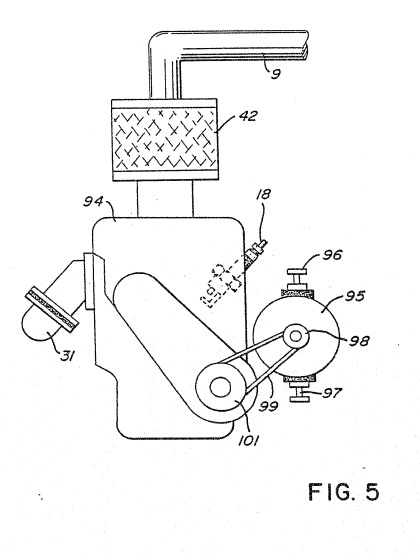

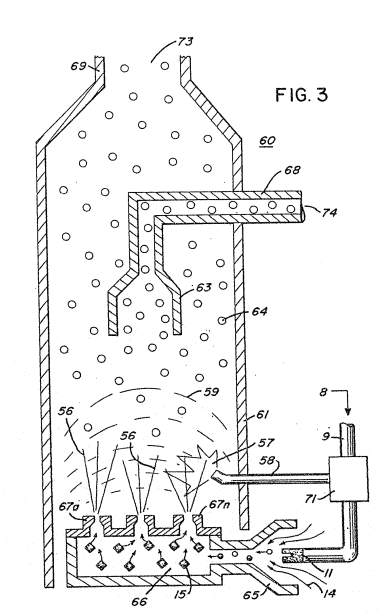

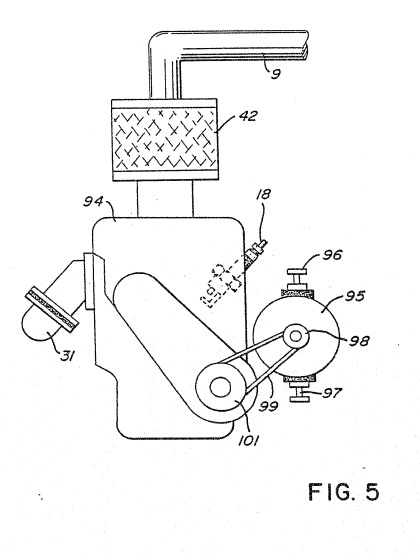

The process occurs as water mist and gases are injected under pressure into, and intimately mixed in the combustion zone and an electrically polarized zone. In the electrically polarized zone, the water mixture is subjected to a unipolar pulsed direct current voltage that is tuned to achieve resonance in accordance with the electrical, mass and other characteristics of the mixture as a dielectric in the environment of the combustion zone. The resonant frequency will vary according to injector configuration and depends upon the physical characteristics, such as mass and volume of water and gases in the zone. As my prior patents and application point out, the resonant condition in the capacitative circuit is determined by the dielectric properties of water: (1) as the dielectric in a capacitor formed by adjacent conductive surfaces and (2) as the water molecule itself is a polar dielectric material. At resonance, current Flow in the resonant electrical circuit will be minimized and voltage will peak. The injector system provides a pressurized fuel mixture for subjection to the resonant environment of the voltage ‘ combustion zone as the mixture is introduced to the zone. In a preferred embodiment, the injector includes concentrically nested serial orifices, one for each of three constituent elements of the fuel mixture. (It may be feasible to combine and process non-combustible and ionized gases in advance of the injector. In this event only two orifices are required, one for the water and the other for the combined gases.) The orifices disperse the water mist and gases under pressure into a conically shaped activation and combustion zone (or locus). Figure 1A shows a transverse cross-section of an injector in which supply lines for water 1 ionized gas 2 and non-combustible gas 3 feed into a distribution disk assembly 4 having concentrically nested orifices. The fuel mixture passes. through a mixing zone 5 and voltage zone 6 created by electrodes or conductive surfaces 7a and 7b (positive) and 8 (negative or ground). Electrical field lines as shown as 6al and 6a2 and 6bl and 6b2. Combustion (i.e., the oxidation of: hydrogen) occurs in the zone 9. Ignition of the hydrogen can be primed by a spark or may occur spontaneously as a result of the exceptionally high volatility of hydrogen. and its presence in a high voltage field. Although a differentiation of the mixing zone, the voltage zone and the combustion zone is made in explaining the invention, that differentiation relates to events or conditions in a process continuum, and ‘as is evident from Figure 1, the zones are not physically discrete. In the zone(s), there is produced an "excited" Mixture of vaporized water mist, ionized gases and other non-combustible gases all of which have been instantaneously released from under high pressure. Simultaneously, the released mixture is exposed to a pulsed voltage in the zone/ locus at a frequency corresponding to electrical resonance. Under these conditions, outer shell electrons of atoms in the water molecule are destabilized and molecular time share is interrupted. Thus, the gas mixture in the injector zone is subjected to physical, electrical and chemical interactive forces which cause a breakdown of the atomic bonding forces of the water molecule. Process parameters are determined based on the size of a particular injector. In an injector sized appropriately for use to provide a fuel mixture to a conventional cylinder in a passenger vehicle automobile engine, the injector may resemble a conventional spark plug. In such an injector, the water orifice is .10 to .15 inch in diameter; the ionized gas orifice is -15 to -20 inch in diameter; and the non-combustible gas orifice is .20 to .25 inch in diameter. In such a configuration, the serial orifices increase in size from the innermost orifice, as appropriate to a concentric configuration. As noted above, the introduction of the fuel components is desirably maintained at a constant rate; maintenance of a back pressure of about 125 pounds per square inch for each of the three fuel gas constituents appears satisfactorily useful for a “spark-plug\* injector. In the Pressurized environment of the injector, spring loaded one-way check valves in each supply line,’ such as 14 and 15, maintain pressure during pulse off times. The voltage zone 6 surrounds the pressurized fuel mixture and. provides an electrically charged environment of pulsed direct current in the range from about 500 to 20,000 and more volts at a frequency tuned into the resonant characteristic of the mixture. This frequency will typically lie within the range of from about 20 KHz to about 50 KHz, dependent, as noted above, on the mass flow of the mixture from the injector and the dielectric property of the mixture. In a, spark-plug sized injector, the voltage zone will typically extend longitudinally about -25 to 1.0 inch to permit sufficient dwell time of the water mist and gas mixture between the conductive sufaces 7 and 8 that form a Capacitor so that resonance occurs at a high voltage pulsed frequency and combustion is triggered. In the zone, an energy wave is formed related to the resonant pulse frequency. The wave continues to pulse through the flame in the combustion zone. The thermal energy produced is released as heat energy. Ina confined zone such as a piston/cylinder engine, gas detonation under resonant conditions produces explosive physical power. In the voltage zone, the time share ratio of the hydrogen and oxygen atoms comprising the individual water molecules in the water mist is upset in accordance with the process explained in my aforementioned patent no. 4,936,961 and application serial no. 07/460,859. To wit, the water molecule which is itself a polar structure, is distended or distorted in shape by being subjected to the polar electric field in the voltage zone. The resonant condition induced in the molecule by the unipolar pulses upsets the molecular bonding of shell electrons such that the water molecule, at resonance, breaks apart into its constituent atoms. In the voltage zone, the water (H20) molecules are excited into an ionized state; and the pre-ionized gas component of the fuel mixture captures the electrons released from the “water molecule. In this manner at the resonant condition, the water molecule is destabilized and the constituent atomic elements of the molecule, 2H and O, are released; and the released hydrogen atoms are available for combustion. The non-combustible gases in the fuel mixture reduce the burn rate of hydrogen to that of a hydrocarbon fuel such as gasoline -or kerosene from its normal burn rate (which is approximately 2.5 times that of gasoline). Hence the presence of non-combustible gases in the fuel mixture moderates energy release and modulate the rate at which the free hydrogen and oxygen molecules combine in the combustion process. The conversion process does not spontaneously occur and the condition in the zone must be carefully fine tuned to achieve an optimum input flow rate for water and the gases corresponding to the maintenance of a resonant condition. The input water mist and gases may likewise be injected into the zone in a physically pulsed \[on/off\] manner corresponding to the resonance achieved. In an internal combustion engine, the resonance of the electrical circuit and the physical pulsing of the input mixture may be required to be related to the combustion cycle of the reciprocating engine. In this regard, one or two conventional spark plugs may require a spark cycle tuned in correspondence to the ‘conversion cycle resonance so that combustion of the mixture will occur. Thus, the input flow, conversion rate and combustion rate are interrelated and optimally should each be tuned in accordance with the circuit resonance at which conversion occurs. The injection system of the present invention is suited to retrofit applications in conventionally fueled gasoline and diesel internal combustion engines and conventionally fueled jet aircraft engines. ##### ##### EXAMPLE 1 Figures 2A, 2B and 2C illustrate a type of injector useful, inter alia as a fuel source for a conventional internal combustion engine. In the cross-section of Figure 2A, reference numerals corresponding to identifying numerals used in Figure 1 show a supply line for water l leading to first distribution disc la and supply line for ionized gas 2, leading to second distribution disc 2a. In the cross section, the supply line for non-combustible gas 3 leading to distribution disc 3a is not illustrated, however, its location as a third line should be self-evident. The three discs comprise distribution disc assembly 4. The supply lines are formed in an electrically insulating body 10 surrounded by electrically conductive sheath/housing 11 having a threaded end segment 12.| [](http://stanslegacy.com/uploads/images/gallery/2022-06/jbbljOtNrspzQXLs-screenshot-from-2022-06-25-16-06-31.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/HCagrcMh2x9XfZlk-screenshot-from-2022-06-25-16-07-16.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/gWsvHKxaNzmtynhm-image-1656188554549.png) |

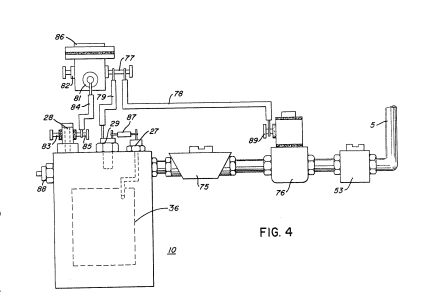

Fuel distribution and management systems useful with the injector of this application are described in my co-pending applications for patent, PCT/US90/6513 and PCT/US90/6407

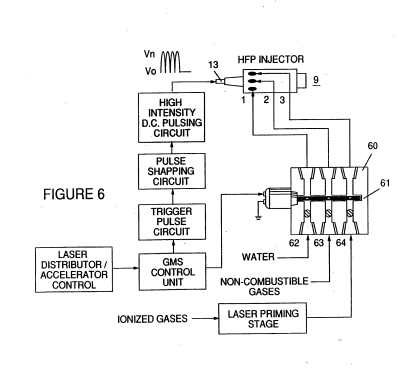

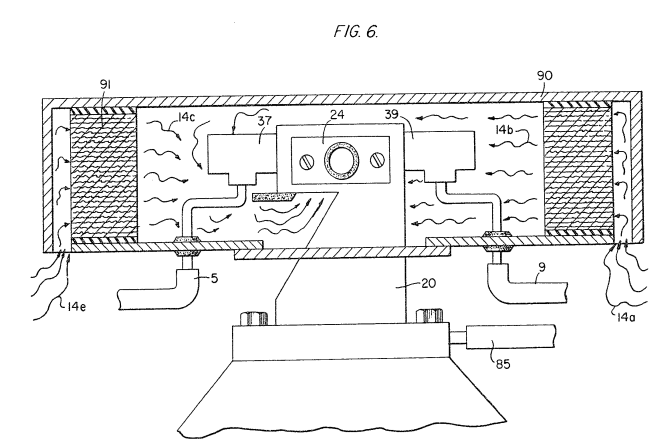

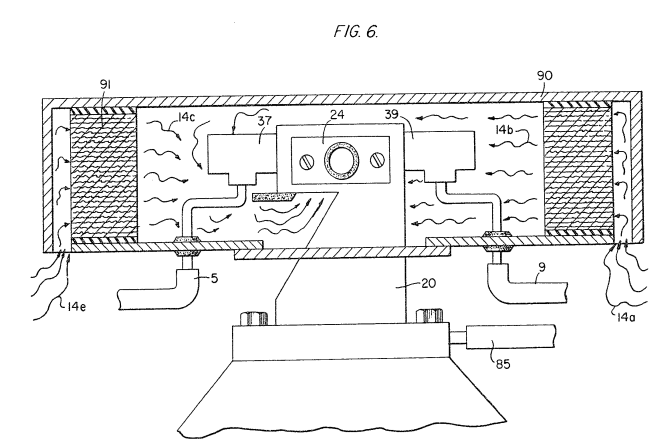

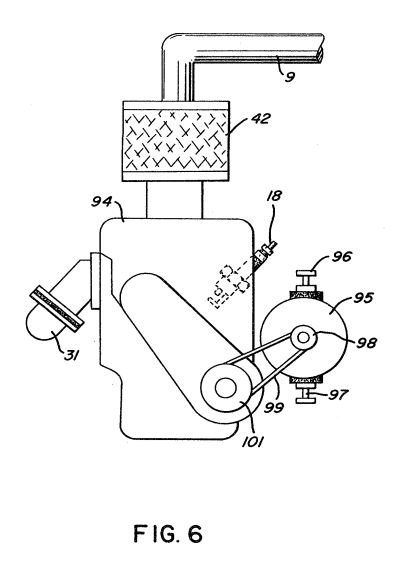

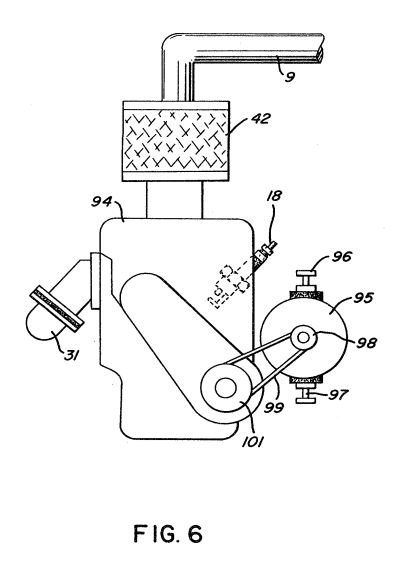

A distribution block for the assembly is shown in Figure 6. In Figure 6 the distribution block pulses and synchronizes the input of the fuel components in sequence with the electrical pulsing circuit. The fuel components are injected into the injector ports in synchronization with the resonant frequency to enhance the energy wave pulse extending from the voltage zone through the flame. In the configuration of Figure 6, the electrical system is interrelated to distribution block 60, gate valve 61 and separate passageways 62, 63, and 64 for fuel components. The distributor produces a trigger pulse which activates a pulse shaping circuit that forms a pulse having a width and amplitude determined by resonance of the mixture and establishes a dwell time for the mixture in the zone to produce combustion. As in my referenced application regarding control and management and distribution systems for a hydrogen containing fuel gas produced from water, the production of hydrogen gas is related to pulse frequency on/off time. In the system shown in Figure 6, the distributor block pulses the fluid media introduced to the injector in relationship to the resonant pulse frequency of the circuit and to the operational on/off gate pulse frequency. In this Manner the rate of water conversion (i.e., the rate of fuel production by the injector) can be regulated and the pattern of resonance in the flame controlled. #### What is claimed is: 1\. The improved method of converting water into a hydrogen containing fuel comprising: > providing a mist of water in a defined zone determined by conductive members, the surfaces: of which define the opposite plates of a capacitive element in a resonant circuit, and > > subjecting the water mist in the zone to a unipolar pulsing electrical signal, such that resonance of the circuit is achieved, whereby hydrogen is disassociated from water molecules in the zone as a gas. 2\. The method of claim 1 in which the resonant circuit is an electrical circuit including an inductive member 3\. The method of Claim 2 in which the inductive member is in series relationship with the capacitive element. 4\. The method of Claim 1 in which non-combustible gases are injected with water into the zone. 5\. The method of Claim 1 in which ionized gases are injected with water into the zone. 6\. The method of Claim 5 in which the ionized gases are subjected to excitation by photons. 7\. The method of Claim 1 or Claim 2 or Claim 3 or Claim 4 or Claim 5 or Claim 6 including the oxidation of the hydrogen gas released to produce thermal energy. 8\. The method of Claim 1 or Claim 2 or Claim 3 or Claim 4 or Claim 5 or Claim 6 including the oxidation of the hydrogen gas released to produce an explosive force of combustion. 9\. The method of Claim 1 or Claim 2 or Claim 3 or Claim 4 or Claim 5 or Claim 6 in which the media in the zone is subjected in the zone to physical pulsing corresponding to the resonance of the circuit. 10\. Apparatus useful in a method for the conversion of water into a hydrogen fuel including: > electrically conductive surfaces that form the opposite surfaces of an electrically capacitive element in a circuit; > > means for injecting water as.a fine mist into the zone defined by the electrically conductive surfaces; and > > means for achieving resonance in the circuit at a frequency determined substantially by the dielectric properties of the water in the zone, whereby hydrogen is disassociated from water molecules in the zone as a gas. 11\. Apparatus in accordance with Claim 10 including means for the injection of gases with water into the zone to produce a mixture and in which the resonant frequency is related to the dielectric properties of the mixture. 12\. Apparatus in accordance with Claim 10 or Claim ll including means for causing ignition of the hydrogen gas. 13\. Apparatus in accordance with Claim 10 or Claim 11 including further means for subjecting the media in the zone to physical pulsing. # CA1234774A1 Hydrogen Generator SystemPDF Download: [SMeyer-CA1234774A1-Hydrogen\_Generator\_System.pdf](http://stanslegacy.com/attachments/45)

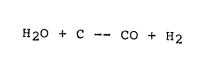

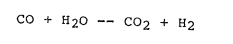

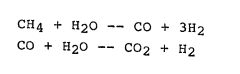

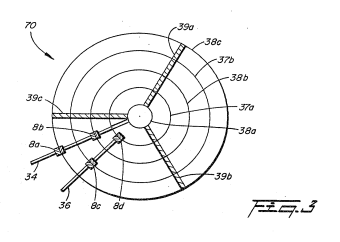

> Y e Consumer and Consommation ~ Corporate Affairs Canada et Corporations Canada > (11) (a) wo. 1-234 774 > (45) ISSUED 880405 > (52) CLASS 204-78 C.R. CL. 204-1644 > (51) INT. CL. C25B 1/04aa) cs) CANADIAN PATENT a2 > (54) Hydrogen Generator System > (72) Meyer, Stanley A., | U.S.A. . : > (21). APPLICATION No. 420,908 (22) FILED 830204 mo ! r No. OF CLAIMS 15 | Canad > DISTRISUTED BY THE PATENT OFFICE, OTTAWA. CCA-274 (11-82) #### ABSTRACT > Process and apparatus for dissociating hydrogen atoms from a water molecule by electrical force. Particularly, the separation of the hydrogen and oxygen atoms from the water molecule by the application of a non-regulated, non- filtered, low-power, direct current voltage electrical potential applied to two non-oxidizing similar metal plates having water passing therebetween. The direct current voltage may be continuous, but the action can be enhanced by pulsing the non-regulated and non-filtered direct current voltage. The apparatus comprises various. constructional configurations and alternative embodiments for segregating the generated hydrogen gas from the oxygen gas. The water need not be pure and may contain contaminants. The release of the hydrogen and oxygen atoms causes the contaminants to fall away, thereby enabling the system to be utilized in a liquid slurry removal system. Alternatively, the recombining of the hydrogen and oxygen would give pure water. ##### Background 1234774 The potential availability of hydrogen as a Supplement to and eventually complete replacement of the present day available fuels is most appreciated. The efficiency of hydrogen as a fuel and its pollution free qualities further enhances its attractiveness. The prior art systems have been Successful in splitting the Sos. . hydrogen atoms from the oxygen. However, cost per Btu is most prohibitive and completely restricts the known process from commercialization. The most commonly understood method of separating the hydrogen and oxygen atoms from water is electrolysis. This comprises placing a direct current voltage to.a solution of water and potassium hydroxide. When current flows, an exchange of ions and electrons occurs between the electrodes. Hydrogen atoms collect at the negative electrode (cathode) and oxygen atoms at the positive electrode (anode). A Separation between electrodes separates the gases. Significantly, this process requires a chemical solution; that is, it does not Operate when using pure water. Furthermore, the cast per million Btu is in the order of three times the cost of gasoline. Other electrolysis processes have been devised and disclosed but are more sophisticated, complicated, complex and costly with attendant unreliability. Another Process under Study. comprises nuclear energy to supply heat in a thermal of the hydrogen dissociation. The problems with the process include the lack of container materials that can withstand temperatures involved (900°C) and a practical method of attaining such temperatures. The addition of inorganic compounds to the water permits lower temperatures but again, adds to the complexity of the process & commercial method known as the Bosch process, consists in passing steam over highly heated carbon in the presence of a Suitable catalyst. Carbon monoxide, CO, and hydrogen are first formed as shown in the following equation:[](http://stanslegacy.com/uploads/images/gallery/2022-06/GQhuj3coI20Sjhio-screenshot-from-2022-06-25-00-42-40.png) The resulting carbon monoxide then reacts with more steam, forming carbon dioxide and hydrogen: [](http://stanslegacy.com/uploads/images/gallery/2022-06/mYfFd4UZ6G4g8HIw-screenshot-from-2022-06-25-00-42-06.png) The carbon dioxide is Separated from the hydrogen by passing the mixture through water under pressure; the carbon dioxide dissolves in the water and leaves the hydrogen pure or nearly so. Another process consists in the action of steam on methane, CH4. The equations for the reactions that take place are: [](http://stanslegacy.com/uploads/images/gallery/2022-06/7wpNBS3fsBfax18b-screenshot-from-2022-06-25-00-42-10.png) The resulting carbon dioxide and hydrogen are separated as in Bosch process. In a similar way, hydrogen may be obtainéd ‘from other hydrocarbons. Hydrogen is also obtained as a by-product from processes designed to prepare other substances, for example in the preparation of chlorine by electrolysis of sodium chloride solution: [](http://stanslegacy.com/uploads/images/gallery/2022-06/Dkjnw1Djl1EKYkFL-screenshot-from-2022-06-25-00-44-00.png) and other important processes. The symbol **(aq)** tells us that the substances are present in water (aqueous) solutions. Finally, there is the natural way of attaining hydrogen by photosynthesis. At best the process is still in the laboratory small-scale stage and those in the art acknowledge the process can produce hydrogen with an efficiency of only 373%. It is generally acknowledged by scientists that every form of hydrogen production must be explored ~~ even 1£ it is too costly, inefficient, or impractical. But, more significantly, hydrogen will be the fuel of the future. The only question remains how and when it will be produced.Reference is made to the publication Cheaper Hydrogen. Popular Science, September 1981, pages 10 through 14, that reviews and updates the above-noted processes.

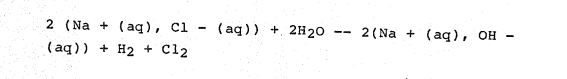

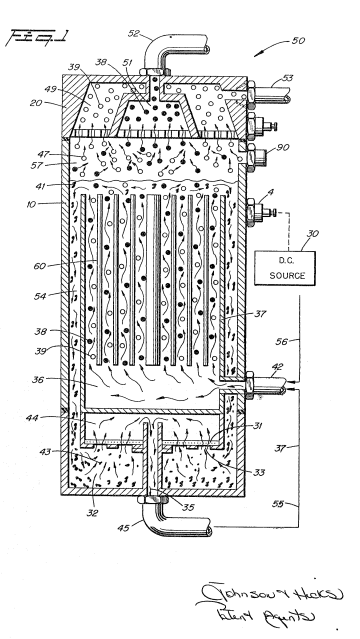

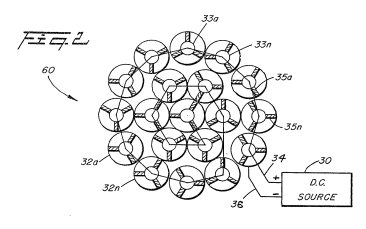

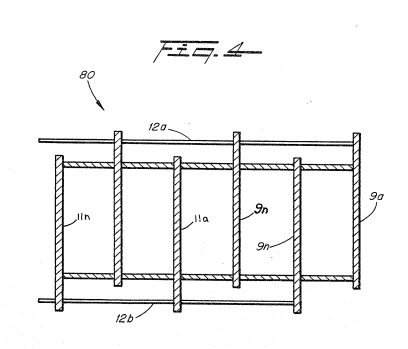

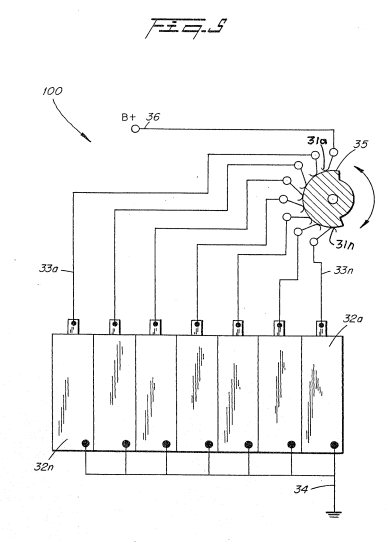

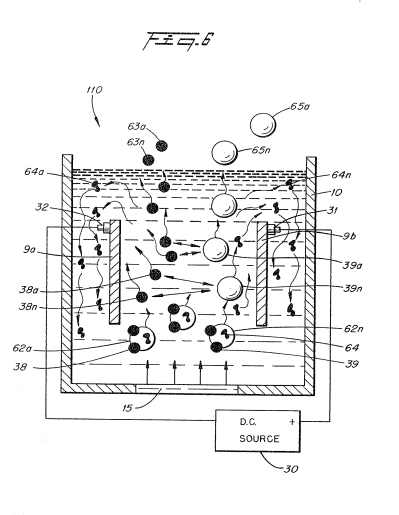

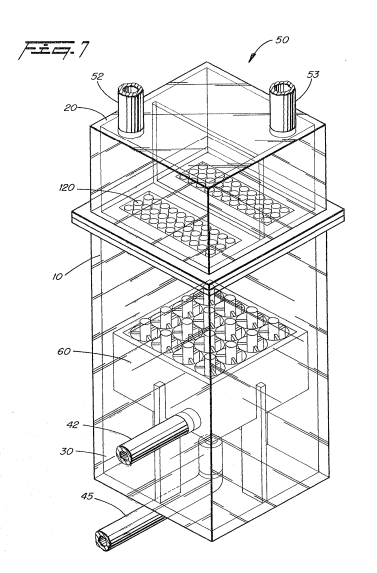

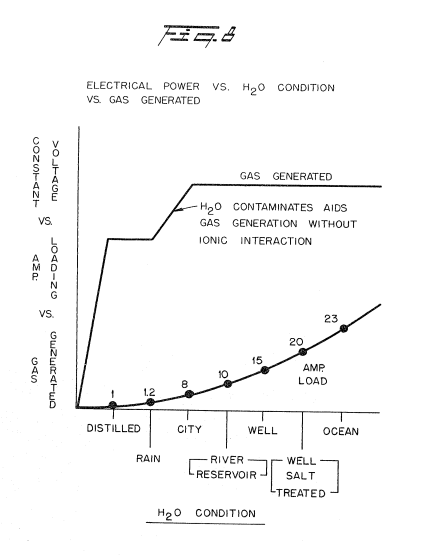

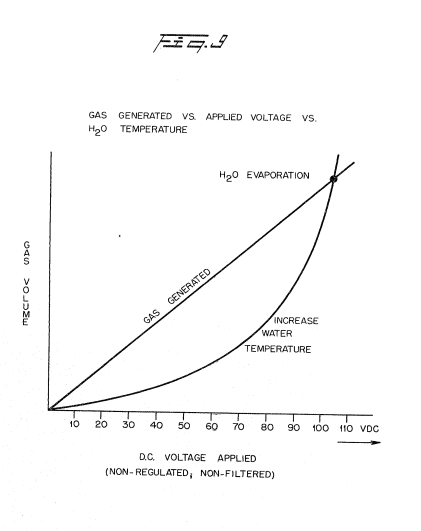

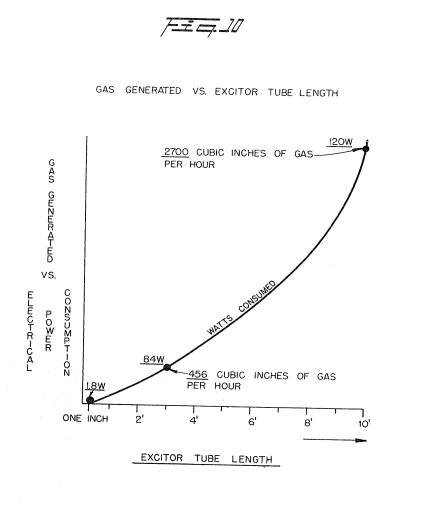

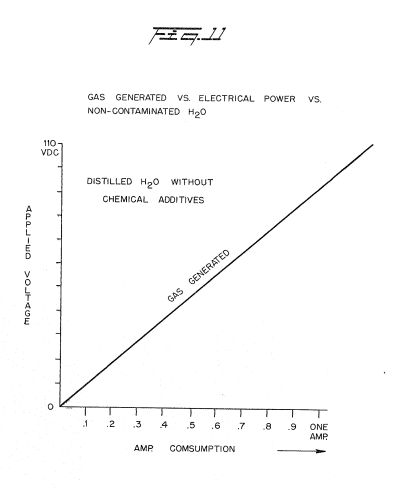

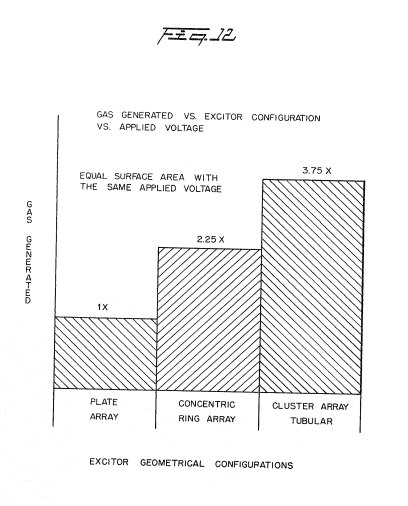

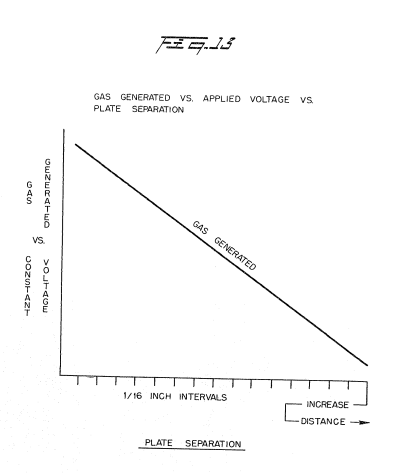

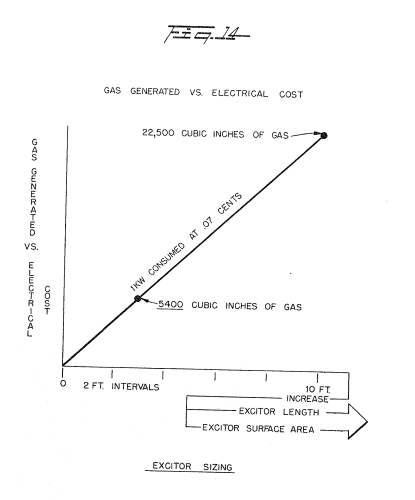

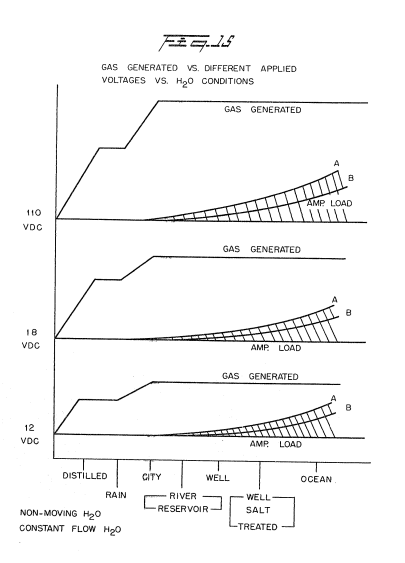

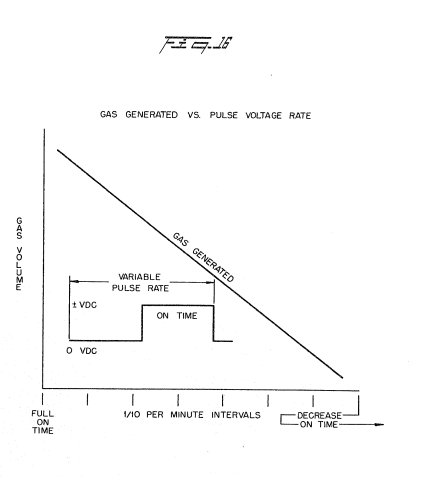

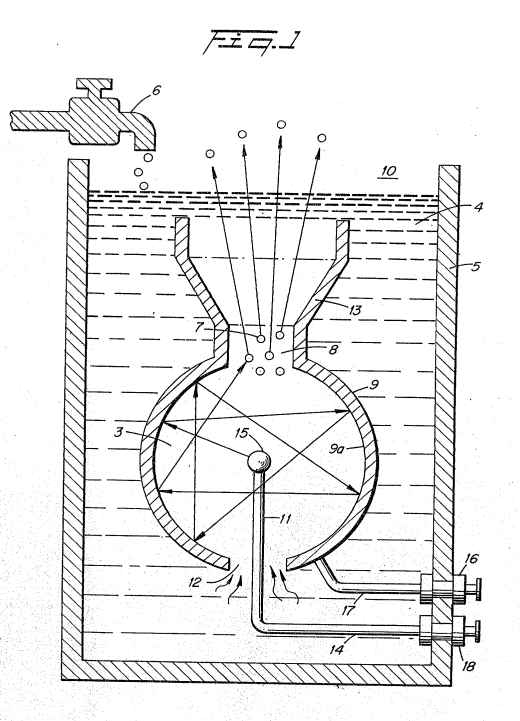

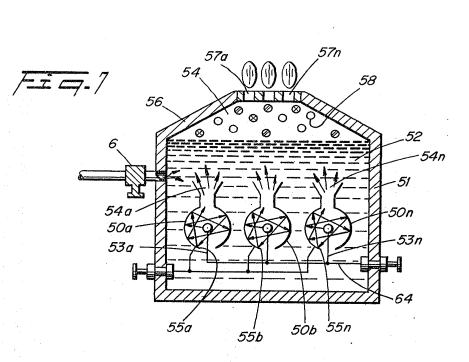

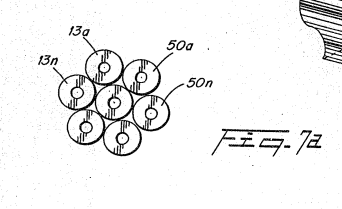

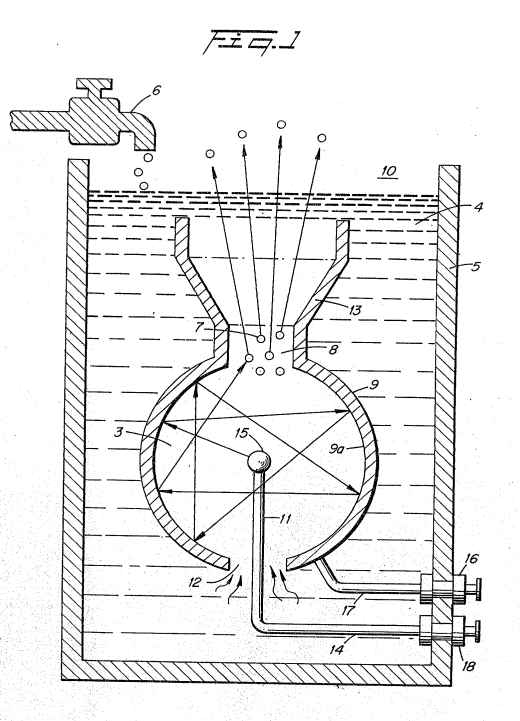

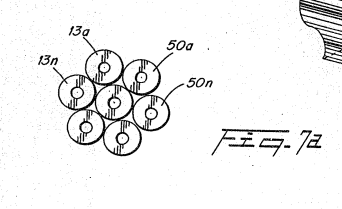

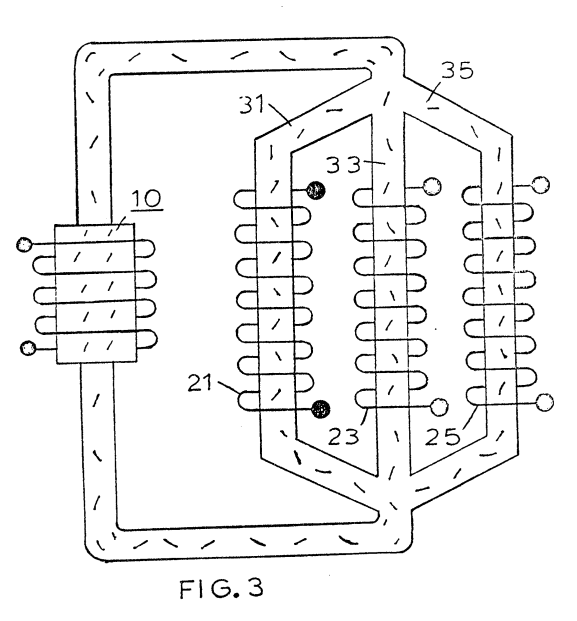

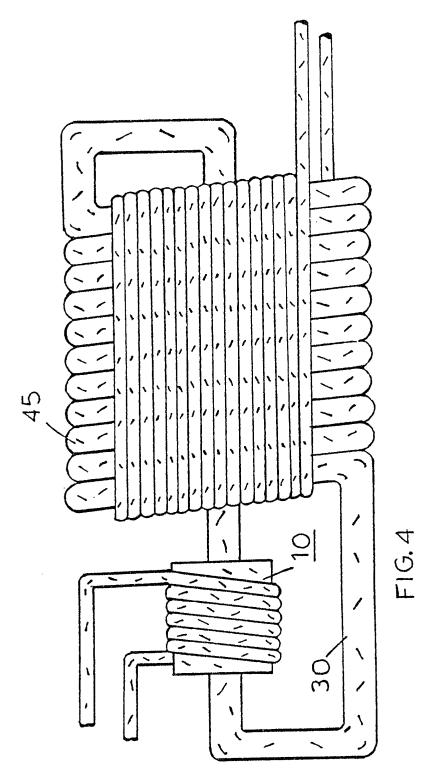

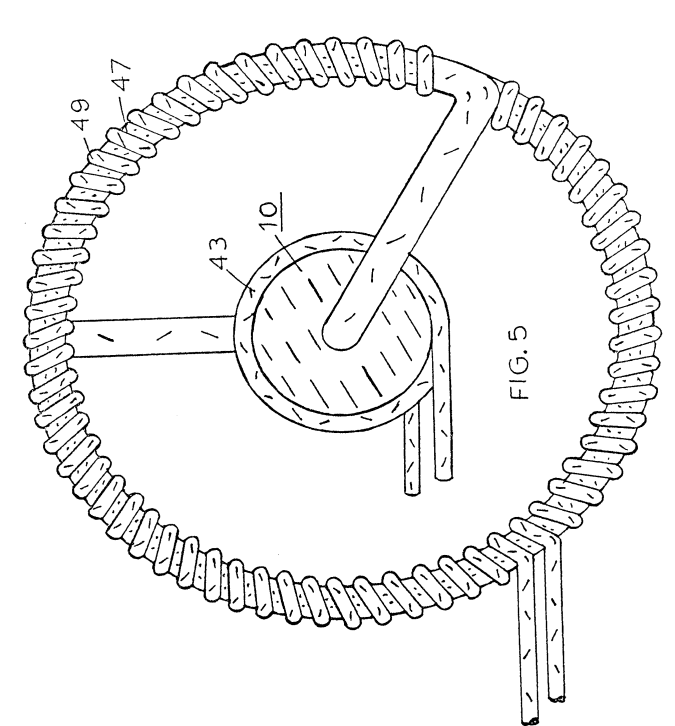

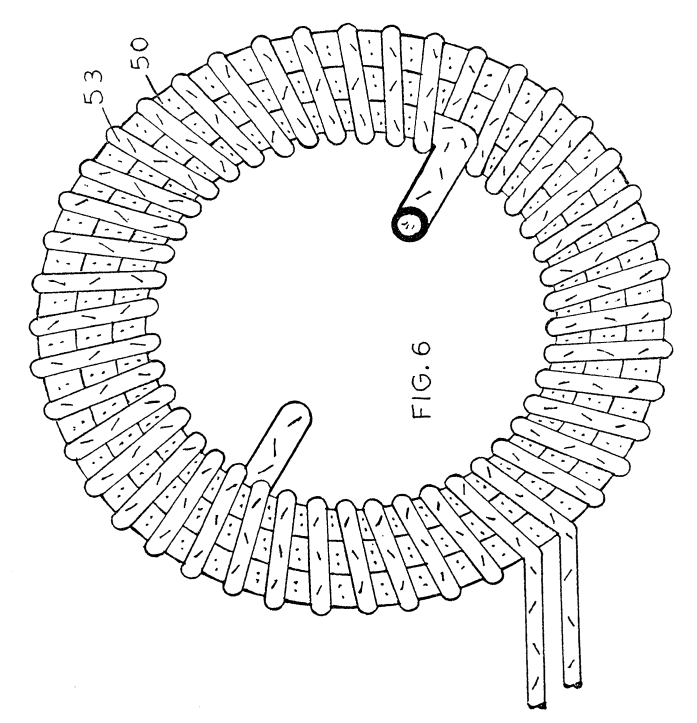

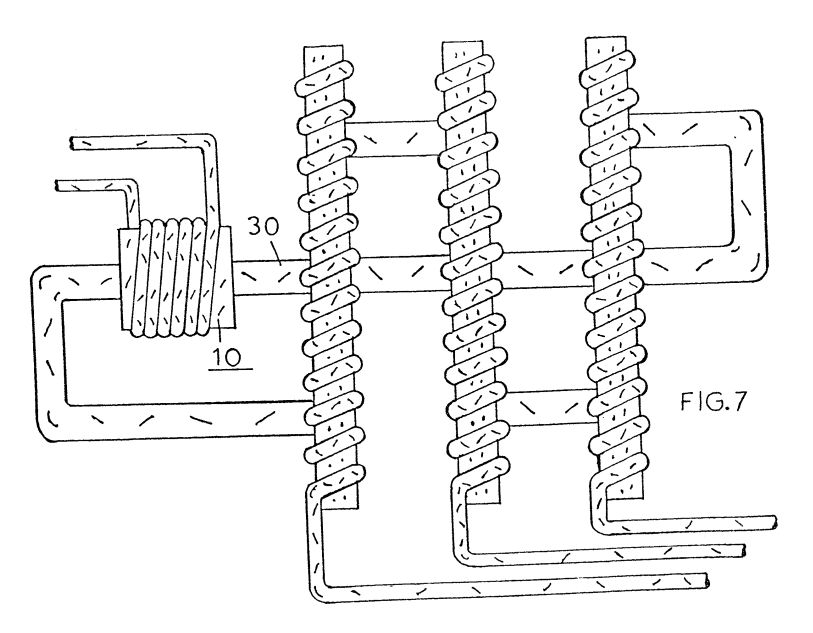

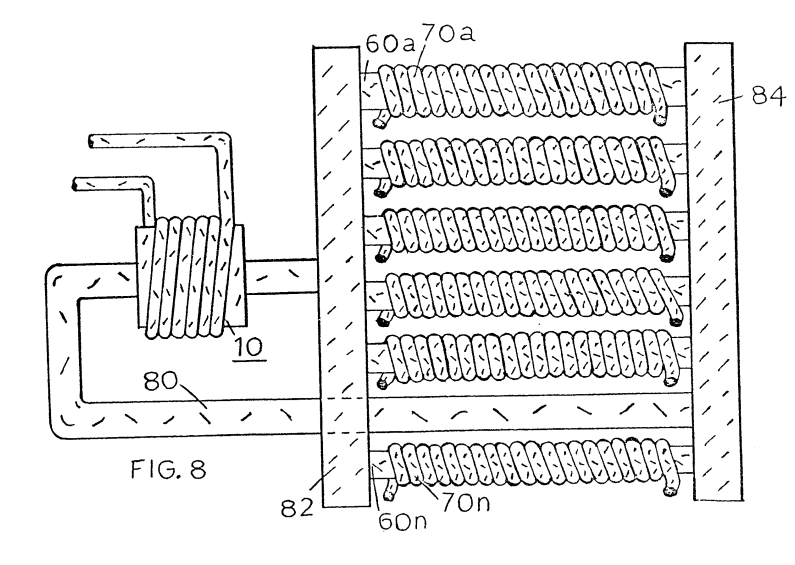

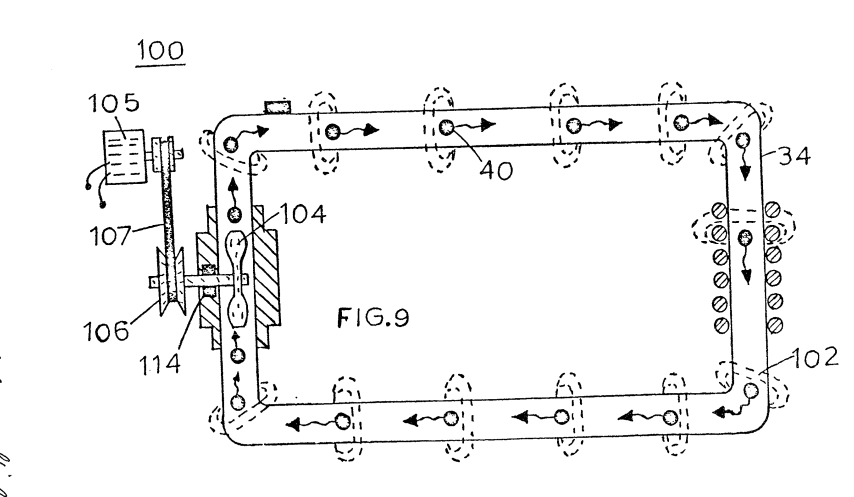

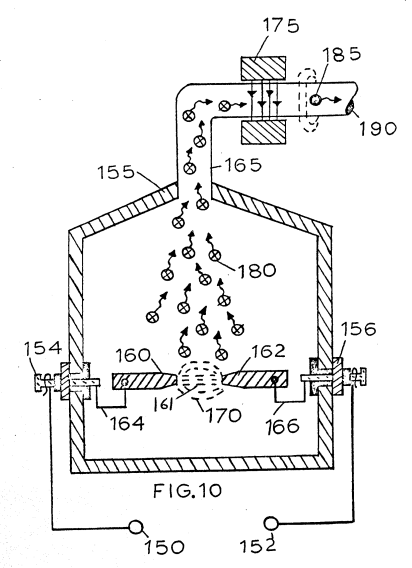

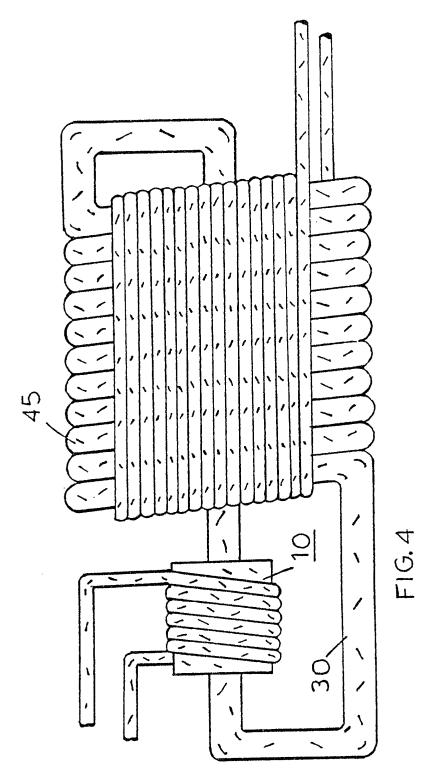

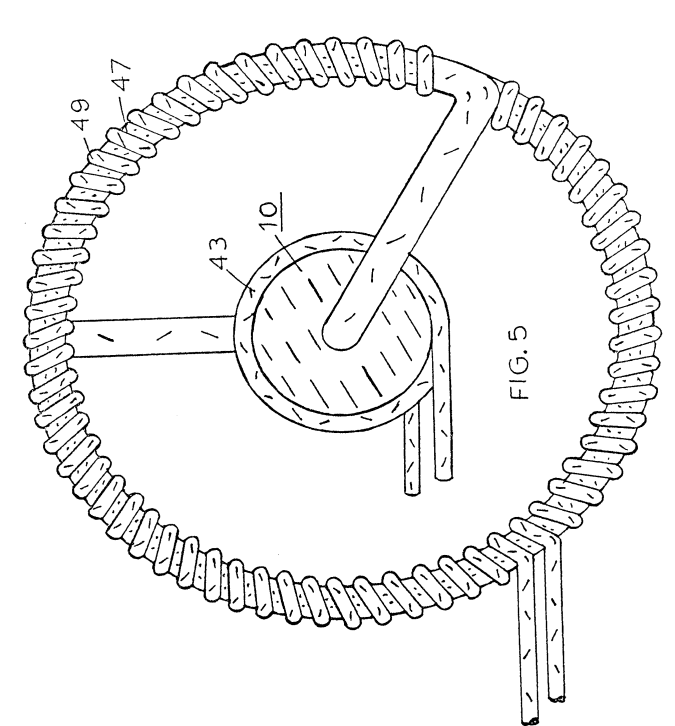

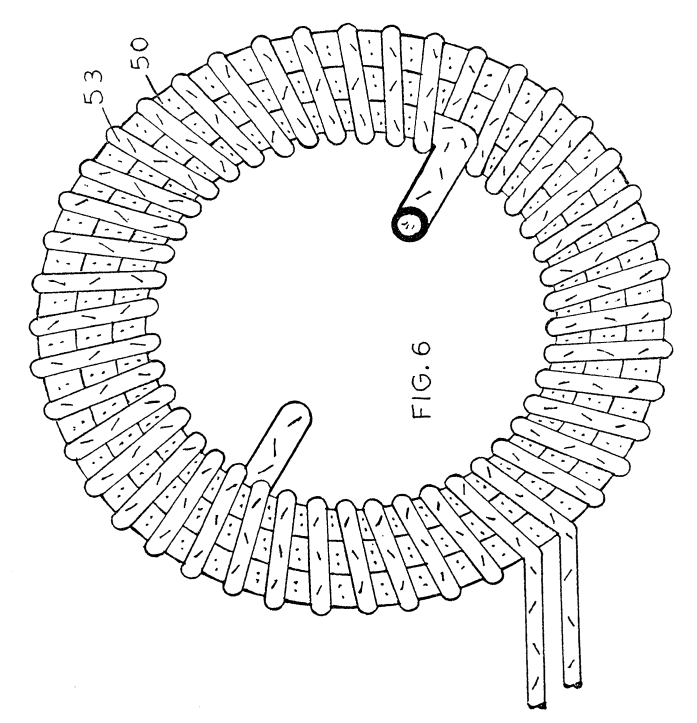

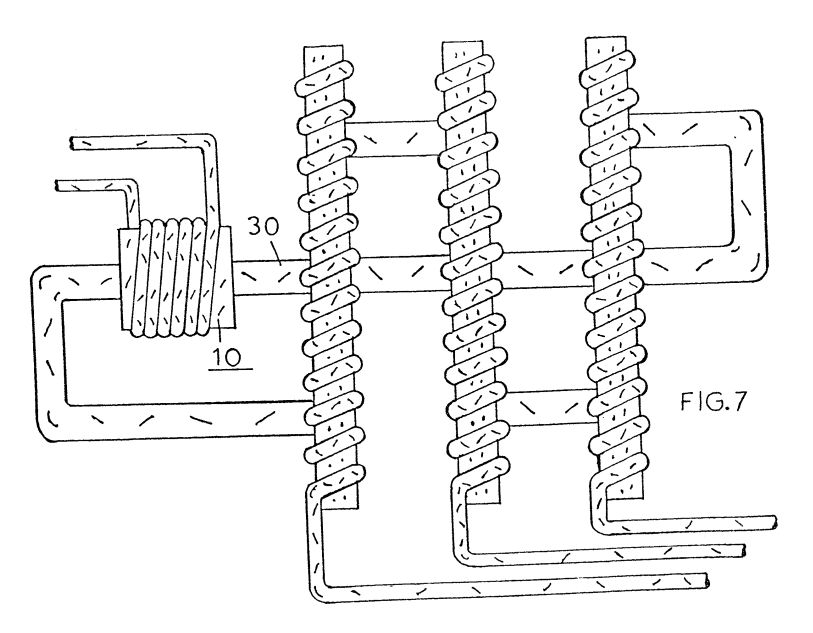

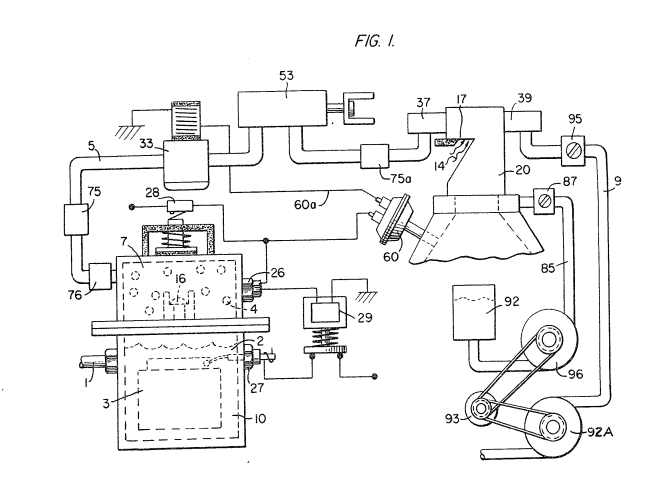

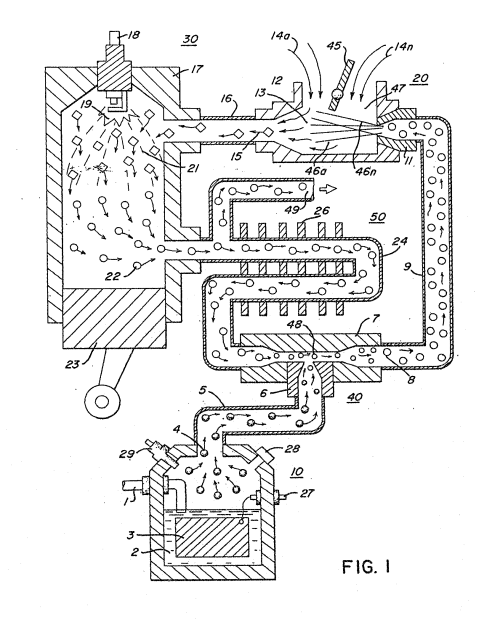

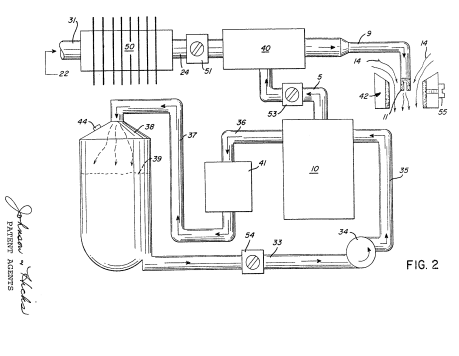

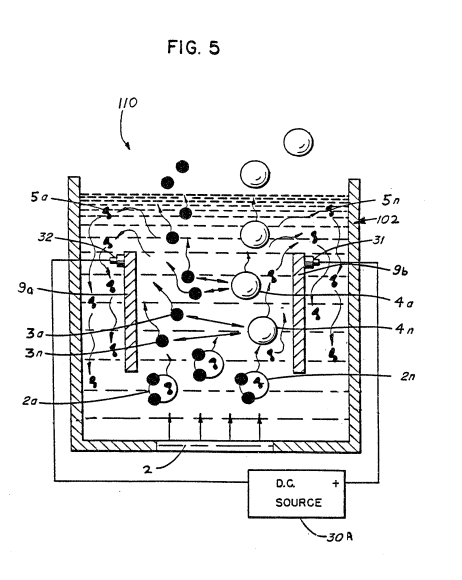

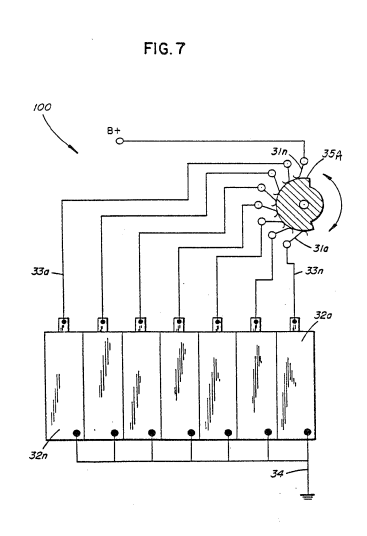

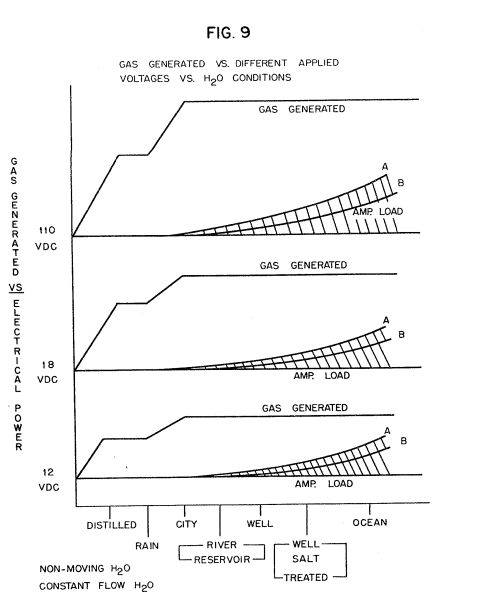

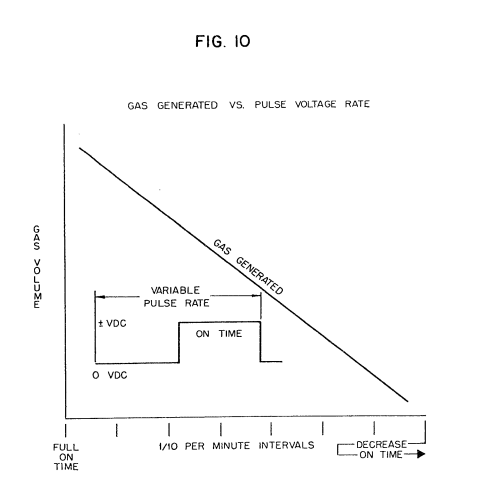

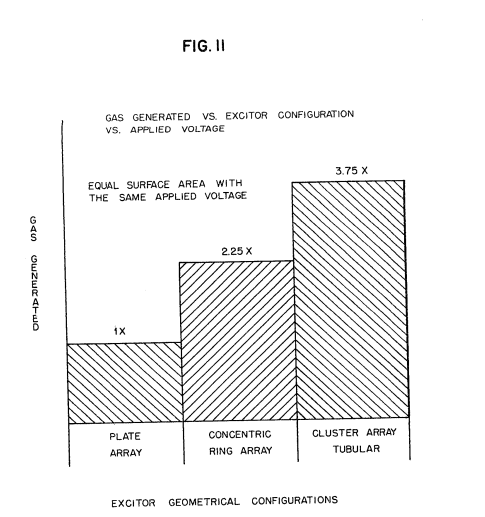

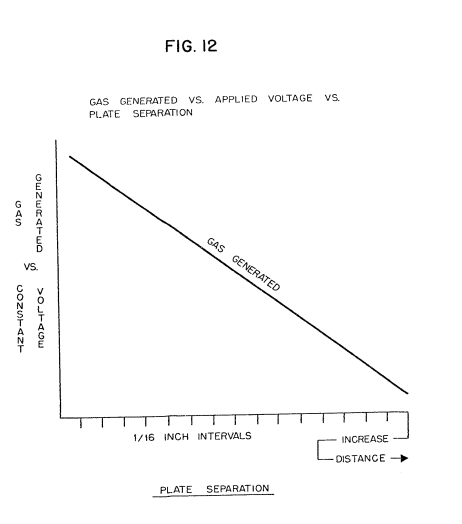

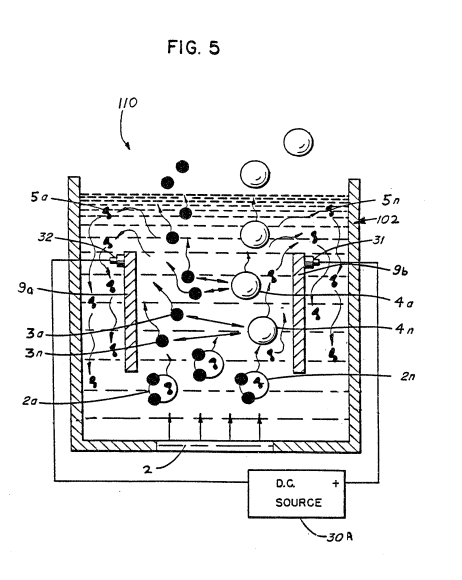

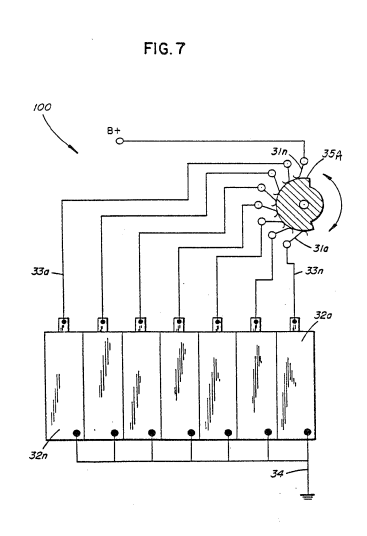

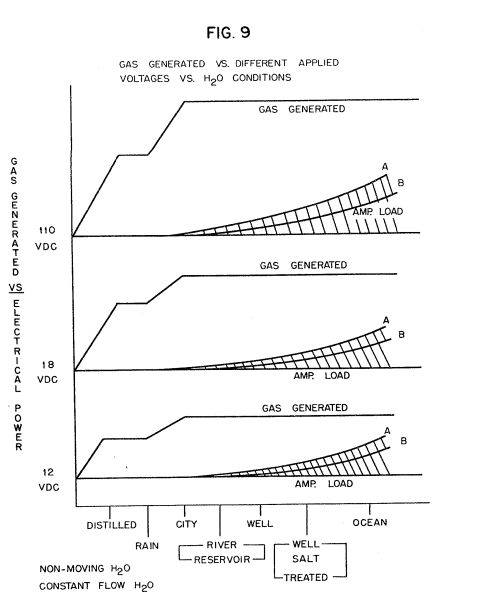

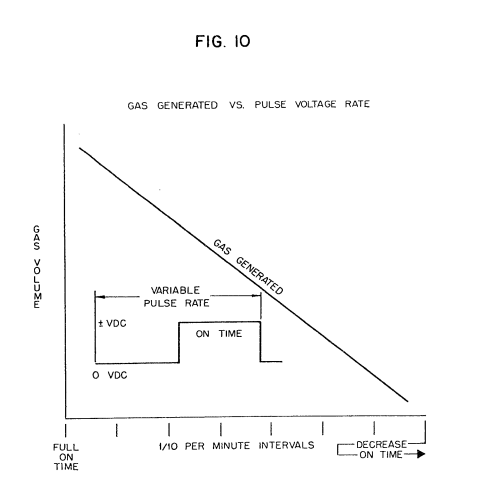

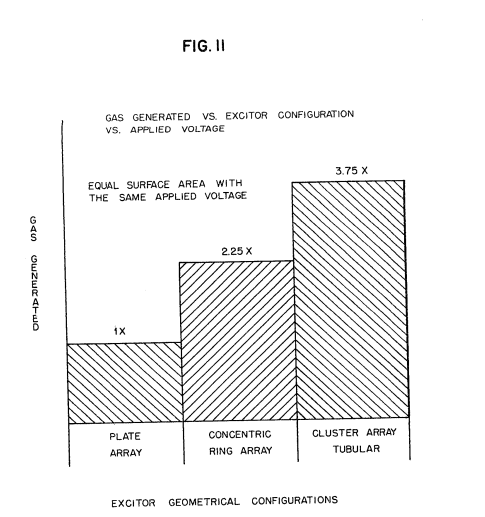

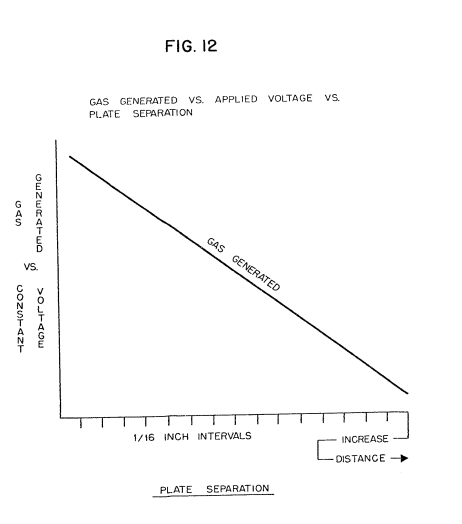

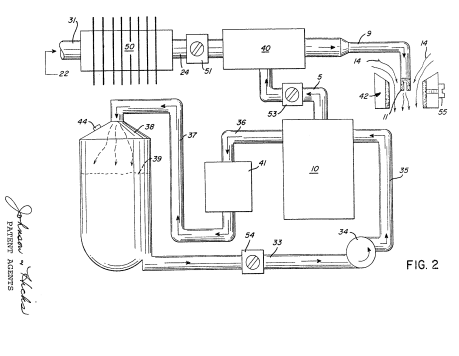

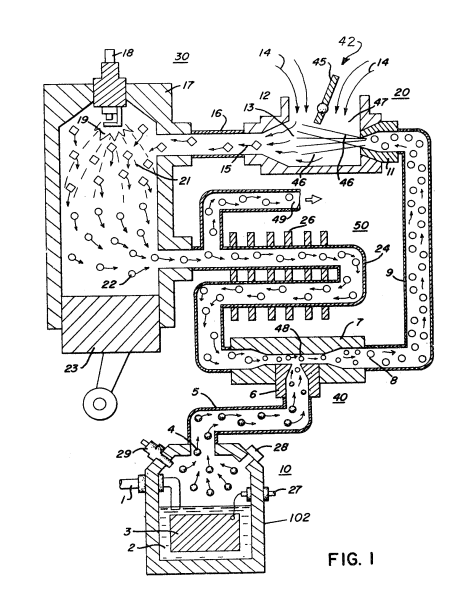

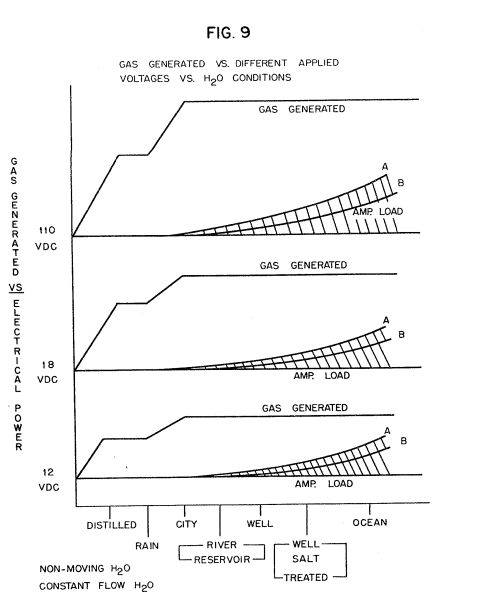

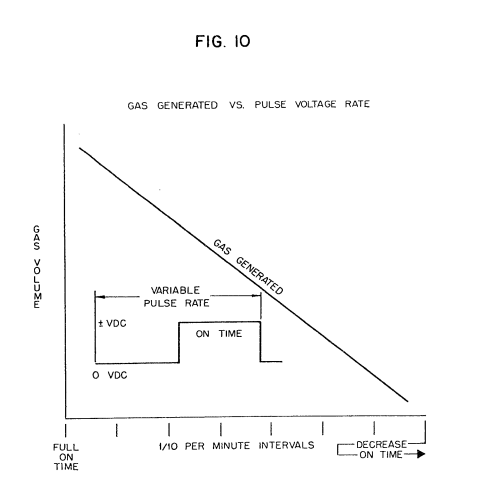

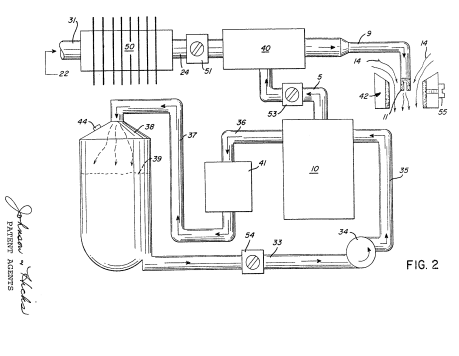

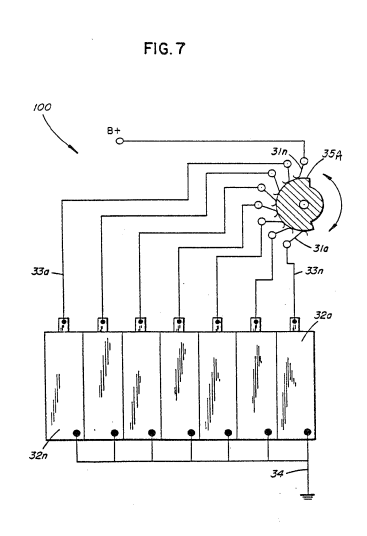

##### Summary of Invention The process of the present invention, unlike those of the prior art, is a simple, efficient, and low cost process for separating the hydrogen and oxygen atoms from water. No chemicals are added to the water and the electrical power utilized is only negligible. In its most fundamental concept the water (which may be uncontaminated or pure water, salt water, or contaminated water) is passed between two plates of similar non-oxidizing metal. The one plate has placed thereon a positive potential and the other a negative potential from a very low direct current voltage power source. The hydrogen atoms are separated and collected for utilization. The contaminants in the water are dissociated and the dissociated parts may be collected and disposed of or utilized. This in turn leads to recombining the hydrogen’ and oxygen to form pure water. The direct current voltage is non-regulated and non-filtered. Experimentation demonstrated that the direct current voltage acts as a **static force** on the water molecules; whereas the rippling direct current voltage acts as a **dynamic force**. Pulsating the direct current further results in a dynamic force and enhances considerably the splitting of the atoms from the water molecules, The apparatus for carrying out the process is extremely simple and can be manufactured most inexpensively. Certain plate arrangements and configurations are disclosed with graphical illustration of relative efficiency. Alternative structure for separating and collecting the hydrogen from the oxygen is disclosed. ##### Objects It is accordingly a principal object of the present invention to provide method and means that is operable for producing hydrogen and oxygen from any natural water irrespective of its purity. Another object of the present invention is to provide a hydrogen/oxygen generator that is operable from very low electrical power, extremely efficient, and wherein the cost o£ Operation is minimal. Another object of the present invention is to provide a. hydrogen/oxygen generator using water containing contaminants, and thereafter recombining the hydrogen/oxygen to form pure water. Still another object of the present invention is to provide a hydrogen/oxygen generator that utilizes apparatus of simple and low cost materials, and which structure can be made in varying sizes, and duplicated without loss of efficiency. Other objects and features of the present invention will become apparent from a reading of the detailed description of the preferred embodiment and its alternative structures when taken in conjunction with the drawings in which: ##### ##### BRIEF DESCRIPTION OF THE DRAWINGS Figure 1 is an illustration in cross~section of the operable constructed preferred embodiment of the present invention; [](http://stanslegacy.com/uploads/images/gallery/2022-06/mLY7btVVcR3JjsJl-screenshot-from-2022-06-25-00-53-18.png) Figure 2 illustrates a coaxial cluster or array of plates utilized in the embodiment of Figure 1; [](http://stanslegacy.com/uploads/images/gallery/2022-06/Ao9KqTXZ4nFHWdrQ-screenshot-from-2022-06-25-00-53-54.png) Figure 3 is a first alternative plate arrangement, a concentric coaxial array; [](http://stanslegacy.com/uploads/images/gallery/2022-06/Hikgx27AT0VxhMBi-screenshot-from-2022-06-25-00-53-58.png) Figure 4 is another alternative plate arrangement, a flat plate array; [](http://stanslegacy.com/uploads/images/gallery/2022-06/tgjspqmga2Y3Ha4F-screenshot-from-2022-06-25-00-54-02.png) Figure 5 diagrammatically illustrates applying a voltage potential to several plates; [](http://stanslegacy.com/uploads/images/gallery/2022-06/HRdSvzDPjPtwTepe-screenshot-from-2022-06-25-00-54-07.png) Figure 6 illustrates the principles of the present invention in its most simplified embodiment; [](http://stanslegacy.com/uploads/images/gallery/2022-06/CnziGnXLMZgEgWZx-screenshot-from-2022-06-25-00-54-13.png) ‘Figure 7 is the preferred embodiment shown in Figure 1 except in this illustration, the view is perspective; [](http://stanslegacy.com/uploads/images/gallery/2022-06/ryrIK0x7Npz5Fqqo-screenshot-from-2022-06-25-00-54-31.png) Figure 8 is a graphical illustration of amperage versus gas generated, and effect as to condition of water; [](http://stanslegacy.com/uploads/images/gallery/2022-06/Lk7cApsW2y4i6AgT-screenshot-from-2022-06-25-00-54-36.png) Figure 9 is a graphical illustration of D.c. voltage versus gas generated, and increases in water temperatures; . . generation [](http://stanslegacy.com/uploads/images/gallery/2022-06/L7XaE0tvcPTZjrp4-screenshot-from-2022-06-25-00-54-41.png) Figure 10 is a graphical illustration of. gas generator versus tube length in a tubular plate arrangement; [](http://stanslegacy.com/uploads/images/gallery/2022-06/1xG7aikX6KQObmo0-screenshot-from-2022-06-25-00-54-46.png) ‘Figure 11 is a graphical illustration of applied power versus gas generated for pure water; [](http://stanslegacy.com/uploads/images/gallery/2022-06/YwmAtZDvqD6Gh1Um-screenshot-from-2022-06-25-00-54-51.png) Figure 12 is a graphical illustration of gas generation for three different geometrical configurations of plate structure; [](http://stanslegacy.com/uploads/images/gallery/2022-06/HGEtvCPGwelpMEG1-screenshot-from-2022-06-25-00-54-56.png) Figure 13 is a graphical illustration of gas generated with the plates having increasing separation; [](http://stanslegacy.com/uploads/images/gallery/2022-06/pmDgFARiIdQmOx19-screenshot-from-2022-06-25-00-55-01.png) Figure 14 is a graphical illustration of electrical costs versus gas generated, and increases in Exciter Plate 5; [](http://stanslegacy.com/uploads/images/gallery/2022-06/a3P8CZIuZL1OSFP8-screenshot-from-2022-06-25-00-55-05.png) Figure 15 is a graphical illustration of different applied power versus gas generated, for various types of water conditions; and [](http://stanslegacy.com/uploads/images/gallery/2022-06/vAjB6EBMs6ohlJ0u-screenshot-from-2022-06-25-00-55-10.png) Figure 16 is a graphical illustration of gas generated versus pulse direct current repetition rate. [](http://stanslegacy.com/uploads/images/gallery/2022-06/KJKMNjZy6frKoyAV-screenshot-from-2022-06-25-00-55-16.png) ##### ##### Detailed Description of Invention as Depicted in Drawings With particular reference now to Figure 6, there is illustrated schematically in cross-section the invention in its most simplified embodiment. A structure 110 contains water supply 15 comprising molecules 62a xxx 62n, of hydrogen 38a xxx 38n, oxygen, 39a xxx 39n, and foreign substances 64a xxx 64n. A pair of plates 9a and 9b consisting of non-oxidizing metal ~- and both of the same metal, are submerged in the water 15. Attached to terminal 32 on the first of the plates 9a is a wire having its other end connected to the negative terminal power source 30 and another wire is connected to terminal 31 on Plate 9b the other end of such wire being connected to the positive terminal of the aforesaid direct current voltage electrical source 30, The direct current voltage applied to the water passing between plates 9a and 9b is sufficient to dissociate the hydrogen atoms 38a xxx 38n and oxygen atoms 39a xxx 39n (appearing as bubbles) from the water molecules 62a xxx 62n. The forceful action of the applied potential attacks the Molecule structure of the water and not its atomic structure. The foreign substance or contaminants 64a xxx 64n are broken” away from the water molecule 62a xxx 62n, and spill over the outside area of the plates 9a and 9b to a collector at the bottom of the tank 10. The hydrogen gas 63a xxx 63n and oxygen gas 65a xxx 65n rises above the liguid. The gases are separated, collected and thereafter utilized all as set forth below. The process shown with the apparatus of Figure 6 is operable, as depicted schematically, in its most crude form. To increase and enhance the action, the process and the apparatus are improved upon as shown in the constructed and preferred embodiment of Figure 1 (a cross~sectional view) and Figure 7 (a perspective view). The voltage source 30 (shown schematically in Figure 5) supplies a direct current voltage that is rectified but not filtered and not regulated. That is, the direct current voltage is rippled and unregulated. The varying amplitude $S3K5, ripples, in terms of applied force act as a constant static physical force. The amount of electrical power required by the hydrogen/oxygen generator of the preferred embodiment, as illustrated, is surprisingly minimal. For the embodiment shown in Figures 1, 2 and 7, the power source 30 supplies 12 volts at J ampere. It can be appreciated, that increasing the voltage would enhance the forceful action upon the water molecule. The correlation of gas generated vs, electrical energy is graphically illustrated in Figure 11. The gas generated is a linear function of the magnitude of voltage applied. However, there is a serious limitation to increasing the voltage. As the voltage/current is increased the temperature of the water increases and eventually reaches a condition where steam is generated -- as illustrated graphically in Figure 9. Further, as shown graphically in Figure 8, the current versus gas , generated is also a function of the type of water utilized. Therefore, in lieu of increasing the electrical power to enhance the action on the water molecules, other conditions must be considered. The first is to alter the plate source direct current voltage waveform, With particular reference to Figure 5 there is illustrated an electronic switch for switching on and off the rippled D.C. output of supply 30. The- ripple is not removed. The plates 32a XXX. 32n are connected to a common ground 34. The positive terminals 33a xxx 33n are connected respectively to contacts 31a Xxx 31n of switch 35 rotatively making and breaking contact with the direct-current voltage source 30. In function the pulsed rippled output voltage functions to forcefully apply to the water molecules a dynamic force, the pulse repetition rate determining the amount of gas generated. Other structured factors affecting the hydrogen gas generation comprise altering (1) plate size, (2) plate spacing, (3) number of plates, and (4) the plate configuration. All of these factors have been taken into consideration in the development of a plate configuration to provide optimum results for a preferred embodiment. With reference to Figure 2, there is shown an array or cluster of tubular plates utilized in the preferred embodiment of Figures 1 and 7. The term "plate" hereinafter, is intended to convey a large area electrical surface; and whether the surface is flat, curved, tubular or otherwise, is of no consequence except as hereinafter defined. Particularly, each tubular plate comprises an outside tube 32a XXX 32n, and an inside tube 33a xxx 33n. Connecting each of the inner tubes 33a xxx 33n is a terminal wire 34; and connecting each of the outside tubes through a common ground is a terminal wire 36. The two terminal wires 34 and 36 are connected to the positive and negative side respectively of the direct current voltage source 30. Intermediate the outside and inside tubes are a series of spacers 35a Xxx 35n.. The coaxial tubes in an array are shown pictorially in the perspective view of Figure.7. With particular reference to Figure 3 there is illustrated, as an alternative to that utilized in the preferred.embodiment, another plate arrangement and configuration... This concentric ring array comprises a series of co-axial radially spaced tubes with equal spacing between adjacent tubes. The center tube 38a and the alternate tubes 38b.and 38c serve as the positive plates connected to positive wire terminal 34. Each of the tubular plates 38a, 38b, and 38c is interconnected via connectors 8a and 8b to wire terminal 34. The three spacers 39a, 39b, and 39c maintain a uniform spacing between the respective tubular plates. With particular reference to Figure 4 there is shown still another plate arrangement and configuration. In this embodiment, shown in cross-section, the positive plates 9a xxx 9n are interconnected by electrode 12a whereas the negative plates lla xxx lin are interconnected by the electrode 12b. With particular reference to Figure 12 there is illustrated graphically the efficiency of the tubular plate array of Figure 2, the cluster tubular array of Figure 3, and the flat plate array of Figure 4. Specifically there is shown the gas generation versus the plate configuration. It can be appreciated from this graph why the embodiment of Figure 1 includes the cluster tubular array of Figure 2. As stated above another factor affecting the gas generation output is the plate separation. With particular reference to Figure 13 there is illustrated graphically plate Spacing versus gas generation. As can be seen, the greater the spacing the less gas generation. The efficiency versus spacing of the plates is a linear decrease with spacing. As stated above, the applied direct current voltage across the positive current voltage plates having water therebetween is a force applied -- in the nature of a physical force -- to the water molecules. The applied force is sufficient to cause the hydrogen and oxygen atoms to dissociate themselves from the Water molecule and anything else that may be included therewith. In the aforementioned prior art system of hydrogen gas generation such as the electrolysis process, it is essential that the water be distilled or otherwise made pure. To determine the relative differences of the amount of gas generated versus the purity of the water, analysis was made of distilled water, rain water, city tap water, river water, well water untreated, well. water treated, and sea water. The results of gas generation versus electrical power are illustrated in Figures 8 and 15 graphically for each of the waters tested. It appears that water containing contaminants aids gas generation; however, the nature of the water contaminants appears to have no significance. The hydrogen atoms and oxygen atoms dissociate themselves from the water molecule. Anything else that may be included in the water is also bombarded loose and overflows the tank 37 and falls to the bottom 43. Having now examined the applied electrical force phenomena the physical configuration of the electrical plates, the power applied, and the condition of the water, reference is made specifically to-the construction, function and operation of the hydrogen gas generator of the present invention which is shown in cross-section in Figure 1 and in perspective in Figure 7. The container 10 is a square elongated box configuration completely enclosing and sealing the components as hereinafter described. Water, from which the hydrogen gas is to be taken, enters via inlet 42 to the chamber 36. The water is pumped or enters under normal pressure from a source via line 56. As mentioned above, the water need not be pure and hence may originate from any source. The water from source 42 enters chamber 36 which is a free area to an open top enclosure 37. The water entering chamber 36 is caused to rise upwardly through the plates of the cluster 60 previously described in more detail relative to Figure 2. Applied to the inner tubular structures is a positive direct current voltage, and to the outer tubular structures of the cluster array 60 is applied a negative direct current voltage. The direct current voltage is applied via terminals 4 connected to a suitable direct current voltage power source 30. The hydrogen gas is depicted in Figure 1 as a solid circle 38 whereas the oxygen gas is depicted as the open circles 39. OSes The separated hydrogen and oxygen“gas rise into the accumulator chamber 47, Not all of the water molecules are broken up into their various atomic components. Thus, the unspent water 41 spills over the top of chamber 37 and drops down through outer chamber 54 and back to reservoir 43. As aforesaid, it is not necessary to utilize pure (uncontaminated) water, the intake water will include several forms of contaminants. As best understood, when the water molecule is bombarded with the dynamic and static electrical force, the contaminants adhering to the water molecules are shaken loose and released therefrom. The contaminants, too, rise to the top of chamber 37 and fill a part of the spillway 41. in that the contaminants do not contain hydrogen or oxygen, there will be no atomic breakup. The combination of water with contaminants drops down into extraction chamber 43. In the extraction chamber 43 most of the sediment or sludge will drop to the bottom of. the chamber 32. The water with most of the sediment removed passes through the ports 33a xxx 33n, through charcoal filter 31, and into return water chamber 44, The uppermost portion of the water in chamber 44 drops into Standpipe. 35. The water cleansed of substantially all contaminants, exits via pipe 45 and then through line 55 and back to inlet pipe 42. The combined water from inlets 55 and 56 is again processed as aforesaid. ##### THE EMBODIMENTS OF THE INVENTION IN WHICH AN EXCLUSIVE PROPERTY OR PRIVILEGE IS CLAIMED ARE DEFINED AS FOLLOWS : 1\. A system for the release of hydrogen and oxygen gas from natural water having no electrolyte added thereto, comprising: > a housing of non-corrosive, non-reactive, and non-oxidizing material, > > simi laa a pair of’electrical voltage conductive plates sSimitarly of . NON Gorrodeble : : : : a non-reactive, 1 and non-oxidizing material positioned in said housing with a spatial relationship to one another, > > means for passing said natural water between said plates; and > > means connecting one of said plates to a negative output terminal and the other of said plates to a positive output terminal of a variable D.c. voltage source which includes circuit means for restricting the current thereof to a negligible value relative to the magnitude of the voltage, Said voltage forming a positive electrical voltage zone adjacent said plate having said positive terminal connected thereto and a negative voltage zone adjacent said plate having said negative output terminal connected thereto, > > voltage when applied to said plates having a sufficient magnitude to cause the hydrogen atoms of the water molecule to be attracted to said negative zone, and the oxygen atoms to be attracted to said positive zone, > > and thereby force the hydrogen atoms and the oxygen atoms to disassociate themselves from the water molecule at a rate in dependence on the magnitude of the voltage applied to said plates. 4234774 2\. The system as set forth in claim 1 including means selectively to vary the voltage and maintain it at a constant level. 3\. The system as set forth in claim 1 wherein said variable voltage source further comprises pulsing circuit means and wherein the rate of release of said hydrogen and oxygen gas is directly related to the repetition rate of the voltage output pulses of said pulsing circuit. 4\. The system as set forth in claim 3 wherein the magnitude of the output voltage of said variable voltage source is interrelated to the pulse repetition rate of the output pulse of sand pulsing circuit, and wherein the rate of the hydrogen and oxygen atoms disassociating from the water molecule is related to the magnitude of said voltage and the pulse repetition rate of said pulses. 5\. The system as set forth in claim 1 wherein said variable voltage source includes means for varying the magnitude of said voltage from 0 volts to in excess of 110 volts and for restricting the current thereof to less than 1 ampere. 6\. The system as set forth in claim 1, characterized in that said non-oxidizing plates are coaxial or alternatively have concentric surfaces. 7\. The system as set forth in claim 1, characterized in that said non-oxidizing plates are a plurality of plates in an array. 8\. The system as set forth in claim 1, characterized in that said non-oxidizing plates are a cluster of coaxial plates in an array. 9\. The system as set forth in claim 1, characterized in that said non-oxidizing housing further comprises a gas collection chamber for maintaining a preset volume of gas under pressure. 10, The system as set forth in claim 7, characterized by switching means interconnected to each of said plates in said array and to said voltage source for switching in and out selected ones of said array of plates from said voltage source. 11\. The system as set forth in the spacing between the plates, surface area of the plates, the configuration of the plates and plates is adapted to be changed claim 1 wherein at least one of the length of the plates, the the the voltage applied to the so as to alter the production number of plates, rate of hydrogen and oxygen gas. 12\. The system as set forth in claim 1 further comprising means to separate the produced hydrogen and oxygen gases. 13\. The process of releasing hydrogen and oxygen gas from natural water having no electrolyte added thereto, comprising: > passing said natural water through a contained area having nen-daorrodable AGR-EOEEOSLVG, non-reactive electrically conductive plates therein, > > a pair of similar non-oxidizing, ’ applying a variable D.C. positive voltage across one of > > said plates and applying a variable D.C. negative voltage across the other of said plates, restricting the current of said variable voltages applied rash to said plates to a negligible value 4p GOS. to said voltage, > > said positive voltage forming a positive voltage zone adjacent said plate having a positive voltage applied thereto and said negative voltage forming a negative voltage zone adjacent the plate having a negative voltage applied thereto, > > Said variable voltages applied to said plates being of sufficent magnitude to cause the positive atoms of the water molecule to be attracted to the negative voltage zone and said plate and the negative atoms of the water molecule to be attracted to the positive voltage zone on said other plate, > > thereby forcing the hydrogen atoms and the oxygen atoms to disassociate themselves from the water molecules at a rate dependent on the magnitude of said variable voltage, > > and varying the magnitude of the variable voltage applied to said plates to vary the rate at which the hydrogen atoms and the oxygen atoms disassociate themselves from the water molecule. 14, The process of claim 13 further comprises pulsing the variable voltage applied to said plates at a variable repetition rate and varying the physical parameters of said plates in an interrelationship with said variable voltages. 15\. The system as set forth in claim 7 further comprising switching means interconnected to each of said plates in said array and to said voltage source for switching in and out selected ones of said array of plates from said voltage source and wherein the number of said plates having said voltage source switched therein is directly related to the rate of hydrogen atoms and oxygen atoms disassociating from said water molecule # CA1234773A1 Resonant Cavity Hydrogen Generator That Operates with a Pulsed Voltage Electrical PotentialPDF Download: [SMeyer-CA1234773A1-Resonant\_Cavity\_Hydrogen\_Generator\_That\_Operates\_with\_a\_Pulsed\_Voltage\_Electrical\_Potential.pdf](http://stanslegacy.com/attachments/46)

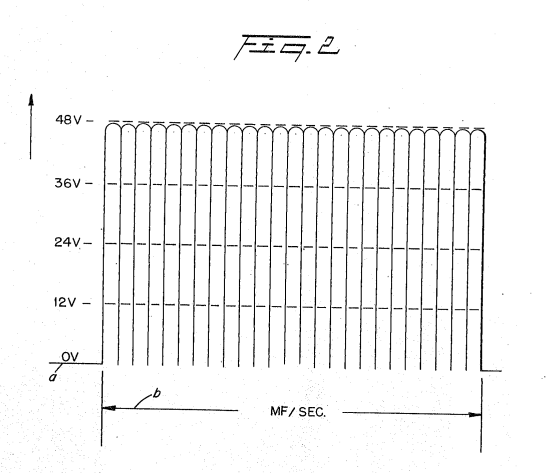

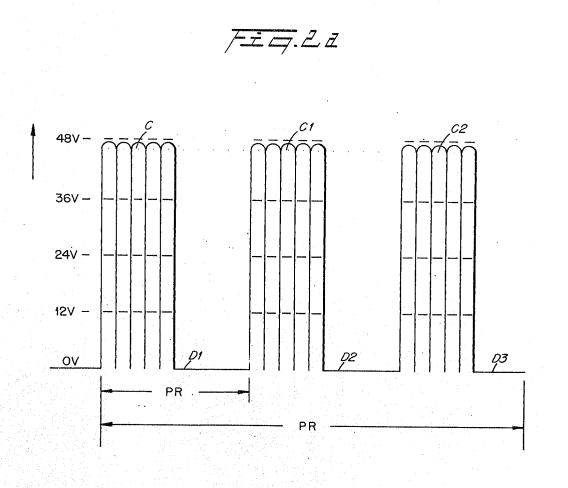

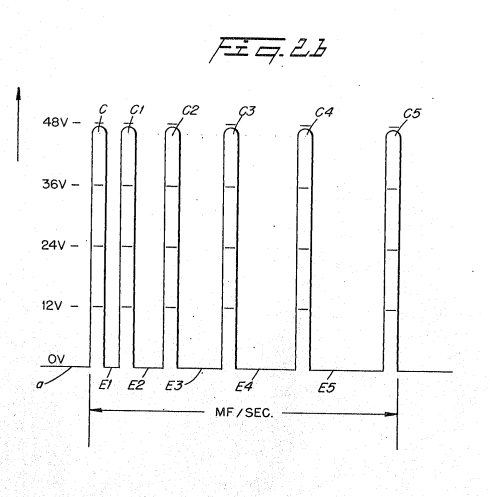

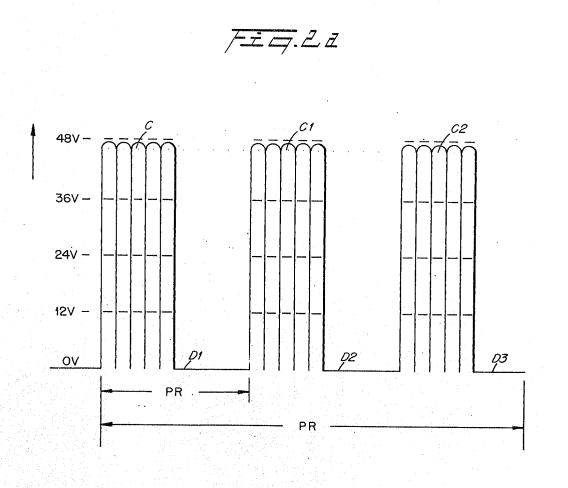

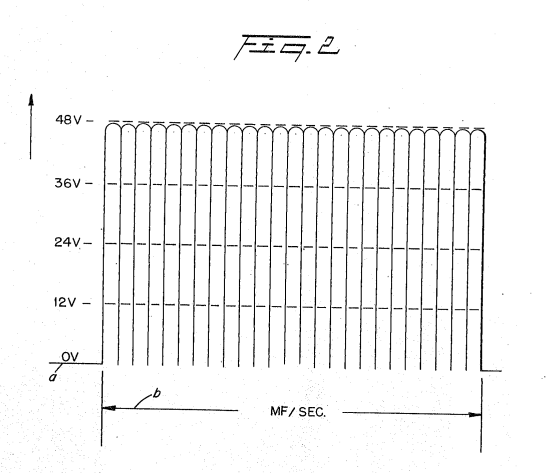

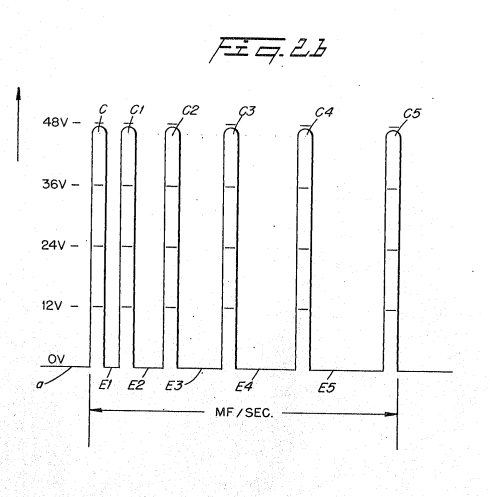

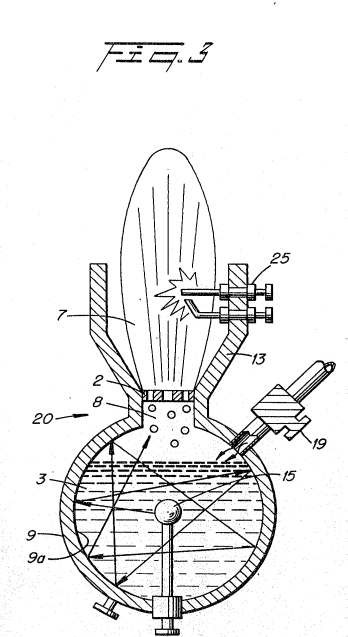

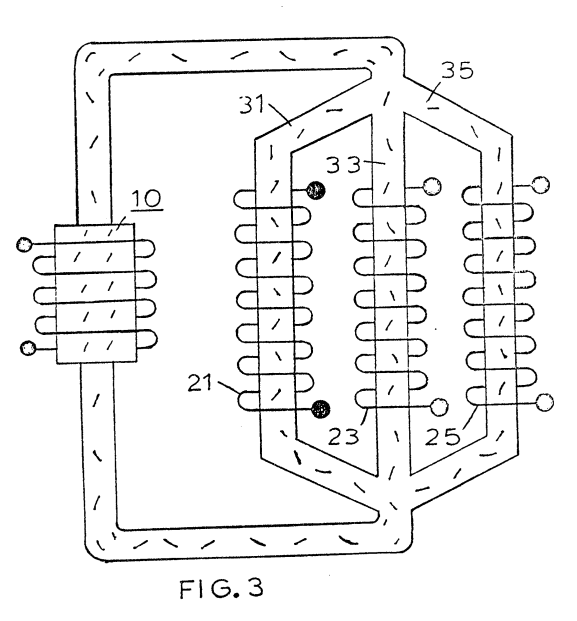

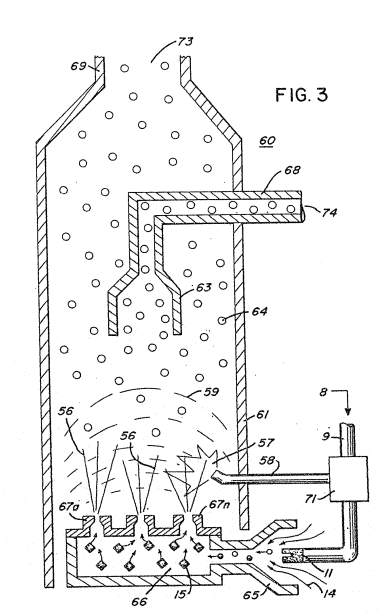

Consumer and Consommation Corporate Affairs Canada al Corporations Canada > (11) (A) No. 1 234 773 > (45) ISSUED 880405 > (52) CLASS 204-78 C.R. CL. 158-14 > (51) INT. CL. ¢C25B 1/04) > (54) Resonant Cavity Hydrogen Generator That Operates With a Pulsed Voltage Electrical Potential > (72) Meyer, Stanley A., U.S.A. > (21) APPLICATION No. 420 ,902 > (22) FILED 830204 > (30) PRIORITY DATE U.S.A. (P65,797) 820924 No. OF CLAIMS 22 > > DISTRIBUTED BY THE PATENT OFFICE, OTTAWA. CCA-274 (11-82) #### ABSTRACT A process is disclosed for producing hydrogen and oxygen gasses from water which includes having water in a cavity which has a selected resonant frequency and applying of voltage potential to exciter elements in contact with the in the cavity so that one element maintains a positive charge and the other a negative charge. The voltage potential is pulsed at a frequency matching the resonant frequency of the cavity. The apparatus includes preferably a spherical shell which is a first exciter element formed of an electrically conductive non-reactive material and defines the boundary of a cavity. The cavity has a pre-determined resonant frequency and a second exciter element of the same material as the the first element is located within the cavity in selected spaced relationship therewith. Water can flow into the cavity gasses produced outflow from the top of the cavity, such gasses being obtained from the water in the cavity when an electrical pulsating potential is applied to the exciter elements ##### ##### RESONANT CAVITY FOR A HYDROGEN GENERATOR CROSS REFERENCE: In the non-electrolysis process disclosed and Claimed in my co-pending Canadain patent application, Serial Number 420,908, filed 4 February 1983, for HYDROGEN GENERATOR SYSTEM, for separating hydrogen and oxygen atoms from water, water is passed between two plates of similar non-oxidizing metal. The one plate has placed thereon a positive potential and the other a negative potential from a very low-direct— current power source. The action of the direct current voltage causes the hydrogen and oxygen atoms to be separated. The contaminants in the water also separated out and may be collected or utilized and disposed of. This in turn lends the process to recombining the hydrogen and oxygen into pure water. The direct current voltage applied to the plates is non-regulated and non-filtered. The direct current acts as a static force on the water molecules whereas the rippling direct current voltage acts as a dynamic force. Pulsating the direct current further acts as a dynamic force and enhances considerably the splitting of the atoms from the water molecules. An increase in voltage potential further increases the hydrogen output. Certain plate arrangements and configurations with graphical illustrations of relative efficiency are disclosed. In my co-pending patent application, supra, it was shown that the hydrogen gas generator is variably increased by varying the construction of the exciters; more particularly, by (1) increasing the area of the plates, (2) reducing the Space between the plates, and (3) altering the physical configuration of the plate. ##### SUMMARY OF THE INVENTION: The basic structure of and principles of operation disclosed in the aforesaid co-pending patent application are utilized. The non-oxidizing exciters are of a construction, spherical in a preferred embodiment, with a given spacing between the positive and negative elements to form a resonant cavity at a given frequency. The direct current voltage is pulsed at a repetition rate (frequency) to match the resonant wavelength. At the matched frequency the action cof the 5 pulsed direct current voltage is enhanced considerably. The forceful action on the water molecule causes the molecules to break into their atomic structure at a much more rapid rate; thereafter, the gas atoms are set into motion within the resonant cavity, thereby increasing velocity to a jet-like action as they are released from a port. The single resonant cavity has a controlled size port for the utilization of the high velocity gasses. The resonant cavity plate structure in a preferred arrangement is an array of elements. The gasses emitted from the array are combined and expelled as high velocity gasses from a common nozzle and utilized. A principal object of the present invention is to provide an improved method and apparatus for the separation of hydrogen/oxygen gasses from water. In accordance with one aspect of the present invention there is provided a process for producing a gaseous medium which includes hydrogen and oxygen from water, comprising: providing at least one pair of spaced apart electrically conductive , non-oxidizing exciter elements in association with a cavity having a selected resonant frequency and in which there is water, said exciter elements being in 4 contact with the water in the cavity, applying a voltage potential to said exciter elements such that one element maintains a positive charge and the other a negative charge, 30. and pulsing the voltage patential at a frequency matching the resonant. frequency of the cavity. In accordance with a further aspect of the present invention there is provided apparatus for producing a gaseous, medium which includes hydrogen and oxygen from water 35 comprising a first exciter element formed of an electrically conductive non-reactive material having a surface which defines the boundaries of a cavity, said cavity having a predetermined resonant frequency with a quantity of water therein, a second exciter element of the said same material within said cavity in selected spaced relationship from said first exciter element, means permitting the inflow of water into said cavity and means permitting the outflow of gasses from said cavity, said gasses being obtained from water in the cavity when an electrical pulsating potential is applied to said exciter elements. ##### ##### BRIEF DESCRIPTION OF DRAWINGS: Figure 1 is a schematic illustration of the structure of the present invention in its most simplified arrangement. [](http://stanslegacy.com/uploads/images/gallery/2022-06/bByhlxezsgl28oj2-screenshot-from-2022-06-25-01-03-24.png) Figures 2, 2A, and 2B, are a series of waveforms illustrating the pulse rate of the direct current to’ match the resonant frequency of the structure of Figure 1.| [](http://stanslegacy.com/uploads/images/gallery/2022-06/xcHYGJAnsirvowzJ-screenshot-from-2022-06-25-01-03-30.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/tnWkcNIAjufxQnAA-screenshot-from-2022-06-25-01-03-35.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/Qt1LQ5CYMf7cyiyV-screenshot-from-2022-06-25-01-03-40.png) |

| [](http://stanslegacy.com/uploads/images/gallery/2022-06/lZ6f43kmSzeePYUU-screenshot-from-2022-06-25-01-04-17.png) | [](http://stanslegacy.com/uploads/images/gallery/2022-06/zXhKLjHmxVKzDSFP-screenshot-from-2022-06-25-01-04-12.png) |

It has been found that the distance between plates of the exciters will have, or can be adjusted to have, **a ‘wavelength or partial wavelength, or a multiple wavelength**, related to the motion of the **water molecule** in **travelling from the one plate to the other**. Therefore, the structure is constructed to be a resonant cavity at some given frequency of the molecular motion.

[](http://stanslegacy.com/uploads/images/gallery/2022-06/bByhlxezsgl28oj2-screenshot-from-2022-06-25-01-03-24.png)With specific reference again to Figure 1, the distance from the outer surface of the central element 15 to the inner surface 9a of the outer spherical element 9 will be at some wavelength correlated to the molecular motion of travel. When the wavelength is matched with a physical force equal in frequency to that wavelength the inner area becomes a resonant cavity. As understood in resonant cavities of an electron nature, the molecules are set into motion and will be bombarded back and forth from the one surface to the next continuously so long as the initial force is applied. In the sphere of Figure 1, the directions that the water molecules may travel from the inner sphere 15 to the surface 9a of the other sphere 9 is of an infinite number. Considering a single molecule, the water molecule's motion will under normal conditions be impeded by the water. If the distance between the inner and outer sphere is co-related to a wavelength related to the frequency of the pulsating direct current applied to the water, the water molecule will be set in motion and thereafter enhanced in motion in the resonant cavity 3 and overcome the impediment of water. Further, the molecule upon striking the inside surface of the outer sphere, will be reflected and directed to an angular surface where it again will be reflected. This action continues indefinitely and will continue until the applied energy is terminated. Thus, a resonant cavity causes the water molecule to travel back and forth continuously and at a velocity that increases geometrically.The above-noted single molecule's motion of travel will be further increased in velocity when it is considered that the **number of water molecules is infinite** and the striking force is not only from **surface-to-surface** but also from **molecule-to-molecule**.