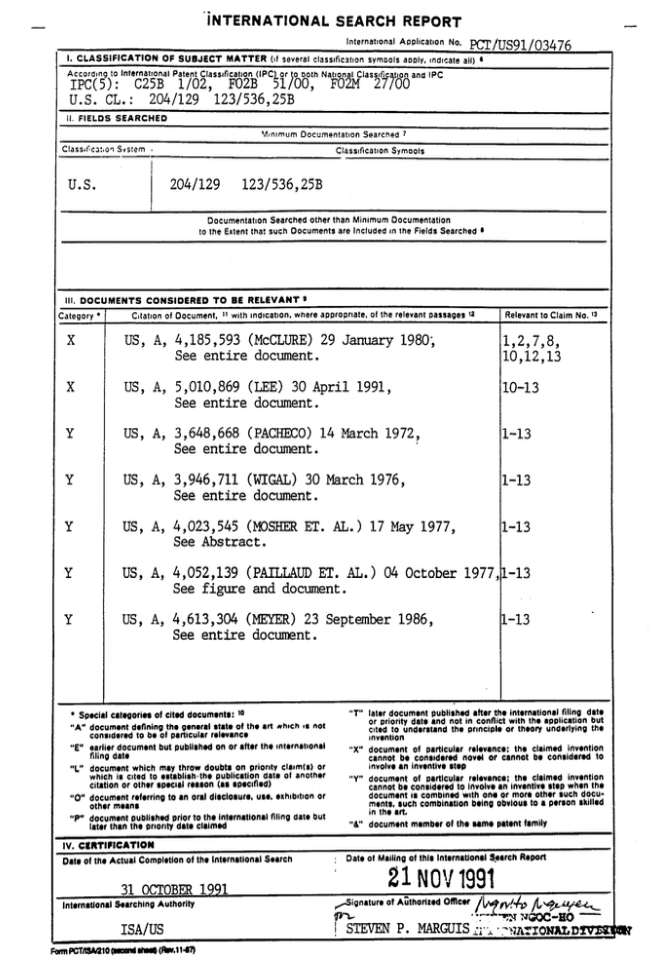

International Patents

1989 Through 1992

- WO9207861A1 - International Patent

- WO8912704A1 - Process And Apparatus For The Production Of Fuel Gas And The Enhanced Release Of Thermal Energy From Such Gas

- WO9222679A1 - Water Fuel Injection System

- WO8901464A3 - Controlled Process for the Production of Thermal Energy from Gases and Apparatus Useful Therefor

- WO9208046A1 - Hydrogen Gas Fuel & Management System For An Internal Combustion Engine

WO9207861A1 - International Patent

PDF Download: SMeyer-WO9207861A1-International_Patent.pdf

This invention relates to electrical circuit systems useful in the operation of a water fuel cell including a water capacitor/resonant cavity for the production of a hydrogen containing fuel gas, such as that described in my United States Letter Patent No. 4,936,961, "Method for the Production of a Fuel Gas", issued on June 26, 1990.

REFERENCE: Patent No. 4,936,961, "Method for the Production of a Fuel Gas", issued on June 26, 1990.

Image Text: A control circuit for a capacitive resonant cavity water capacitor cell (7) for the production of a hydrogen containing fuel gas has a resonant scanning circuit cooperating with a resonance detector and PLL circuit to produce pulses. The pulses are fed into the primary (TX1) transformer. The secondary (TX2) transformer is connected to the resonant cavity water capacitor cell (7) via a diode and resonant charging chokes (TX4, TX5).

In my aforesaid Letters Patent for a method for the production of a fuel gas, voltage pulses applied to plates of a water capacitor tune into the dielectric properties of the water and attenuate the electrical forces between the hydrogen and oxygen atoms of the molecule. The attenuation of the electrical forces results in a change in the molecular electrical field and the covalent atomic bonding forces of the hydrogen and oxygen atoms. When resonance is achieved, the atomic bond of the molecule is broken, and the atoms of the molecule disassociate. At resonance, the current (amp) draw from a power source to the water capacitor is minimized and voltage across the water capacitor increases. Electron flow is not permitted (except at the minimum, corresponding to leakage resulting from the residual conductive properties of water).

For the process to continue, however, a resonant condition must be maintained.

Because of the electrical polarity of the water molecule, the fields produced in the water capacitor respectively attract and repel the opposite and like charges in the molecule, and the forces eventually achieved at resonance are such that the strength of the covalent bonding force in the water molecule is exceeded, and the atoms of the water molecule (which are normally in an electron sharing mode) disassociate. Upon disassociation, the formerly shared bonding electrons migrate to the hydrogen nuclei, and both the hydrogen and oxygen revert to net zero electrical charge. The atoms are released from the water as a gas mixture.

In the invention herein, a control circuit for a resonant cavity water capacitor cell utilized for the production of a hydrogen containing fuel gas is provided.

The circuit includes an isolation means such as a transformer having a ferromagnetic, ceramic or other electromagnetic material core and having one side of a secondary coil connected in series with a high speed Switching diode to one plate of the water capacitor of the resonant cavity and the other side of the secondary coil connected to the other plate of the water capacitor to form a closed loop electronic circuit utilizing the dielectric properties of water as part of the electronic resonant circuit. The primary coil of the isolation transformer is connected to a pulse generation means. The secondary coil of the transformer may include segments that form resonant charging choke circuits in series with the water capacitor plates.

In the pulse generation means, an adjustable first, resonant frequency generator and a second gated pulse frequency generator are provided. A gate pulse controls the number of the pulses produced by the resonant frequency generator sent to the primary coil during a period determined by the gate frequency of the second pulse generator.

The invention also includes a means for sensing the occurrence of a resonant condition in the water capacitor/resonant cavity, which when a ferromagnetic or electromagnetic core is used, may be a pickup coil on the transformer core. The sensing means is interconnected to a scanning circuit and a phase lock loop circuit, whereby the pulsing frequency to the primary coil of the transformer is maintained at a sensed frequency corresponding to a resonant condition in the water capacitor.

Control means are provided in the circuit for adjusting the amplitude of a pulsing cycle sent to the primary coil and for maintaining the frequency of the pulsing cycle at a constant frequency regardless of pulse amplitude. In addition, the gated pulse frequency generator may be operatively interconnected with a sensor that monitors the rate of gas production from the cell and controls the number of pulses from the resonant frequency generator sent to the cell in a gated frequency in a correspondence with the rate of gas production. The sensor may be a gas pressure sensor in an enclosed water capacitor resonant cavity which also includes a gas outlet. The gas pressure sensor is operatively connected to the circuit to determine the rate of gas production with respect to ambient gas pressure in the water capacitor enclosure.

Thus, an omnibus control circuit and its discrete elements for maintaining and controlling the resonance and other aspects of the release of gas from a resonant cavity water cell is described herein and illustrated in the drawings which depict the following:

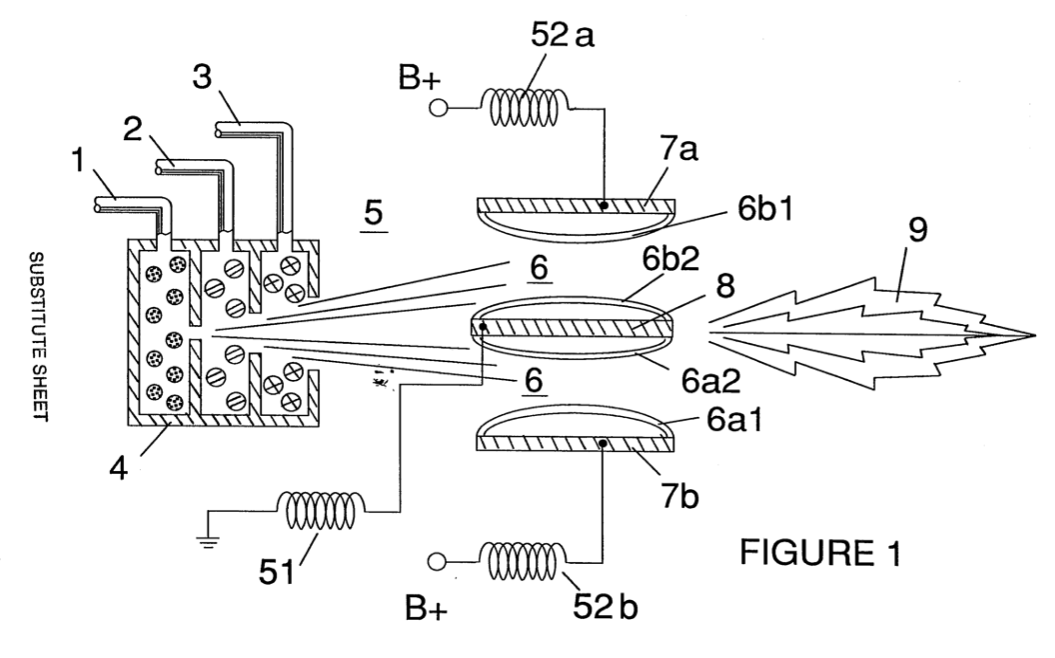

Figure 1 is a block diagram of an overall control circuit showing the interrelationship of sub-cireuits, the pulsing core/resonant circuit and the water capacitor resonant cavity.

Figure 1 - Overall Control Circuit Block Diagram

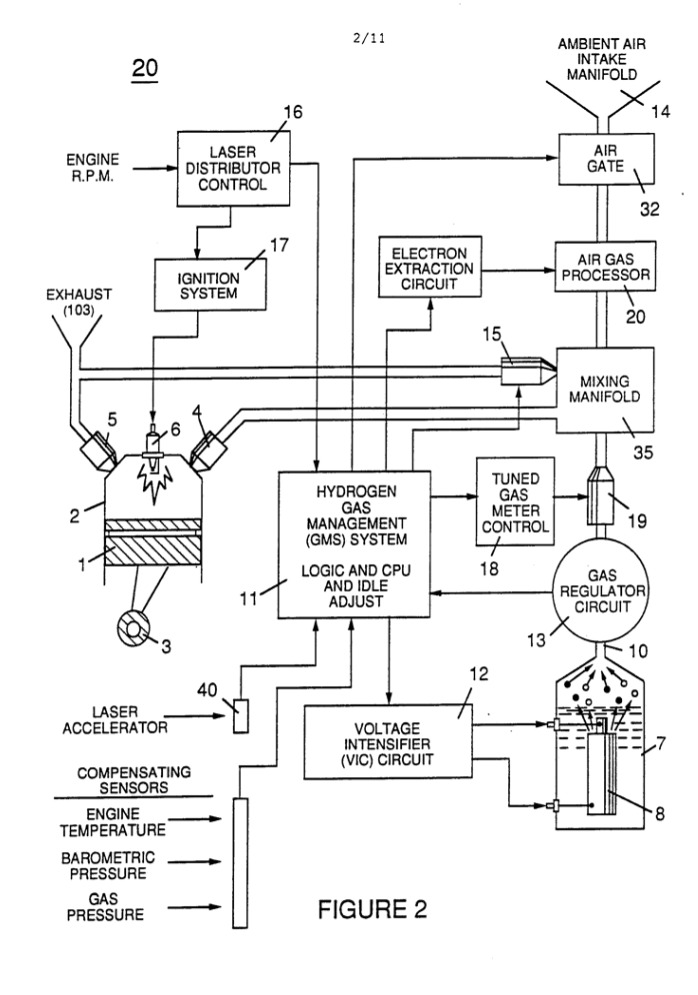

Figure 2 shows a type of digital control means for regulating the ultimate rate of gas production as determined by an external input. (Such a control means would correspond, for example, to the accelerator in an automobile or a building thermostat control.)

Figure 2 - Digital Control Means

Figure 3 shows an analog voltage generator.

Figure 3 - Analog Voltage Generator

Figure 4 is a voltage amplitude control circuit interconnected with the voltage generator and one side of the primary coil of the pulsing core.

Figure 4 - Voltage Amplitude Control Circuit

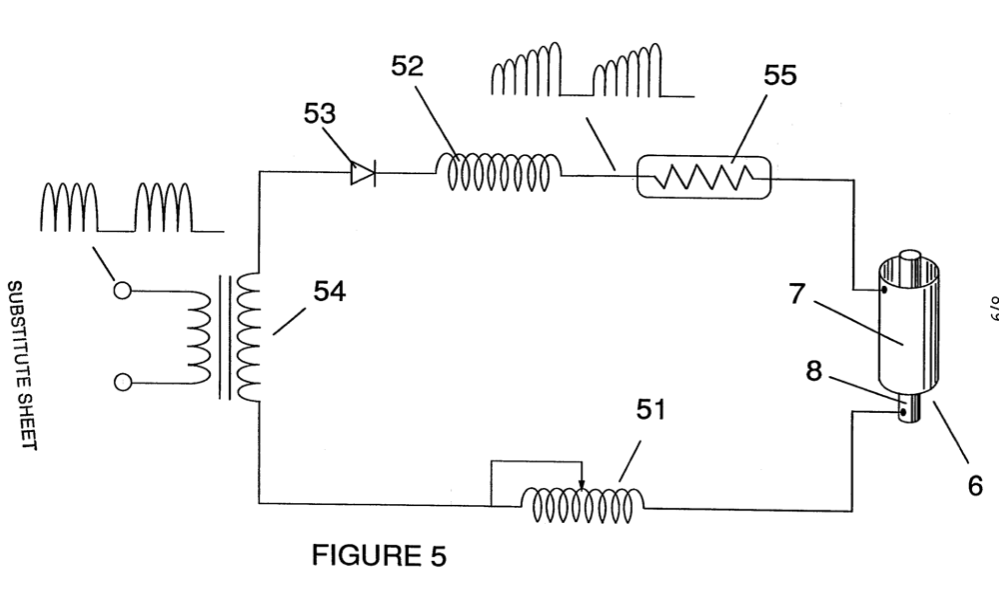

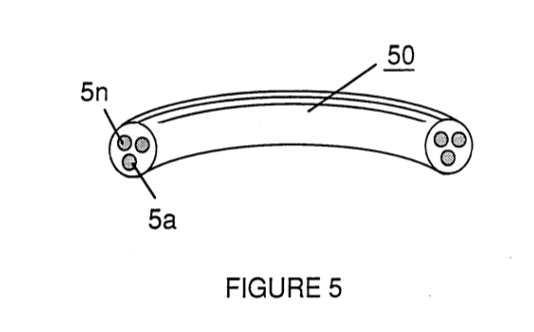

Figure 5 is the cell driver circuit that is connected with the opposite side of the primary coil of the pulsing core.

Figure 5 - Cell Driver Circuit

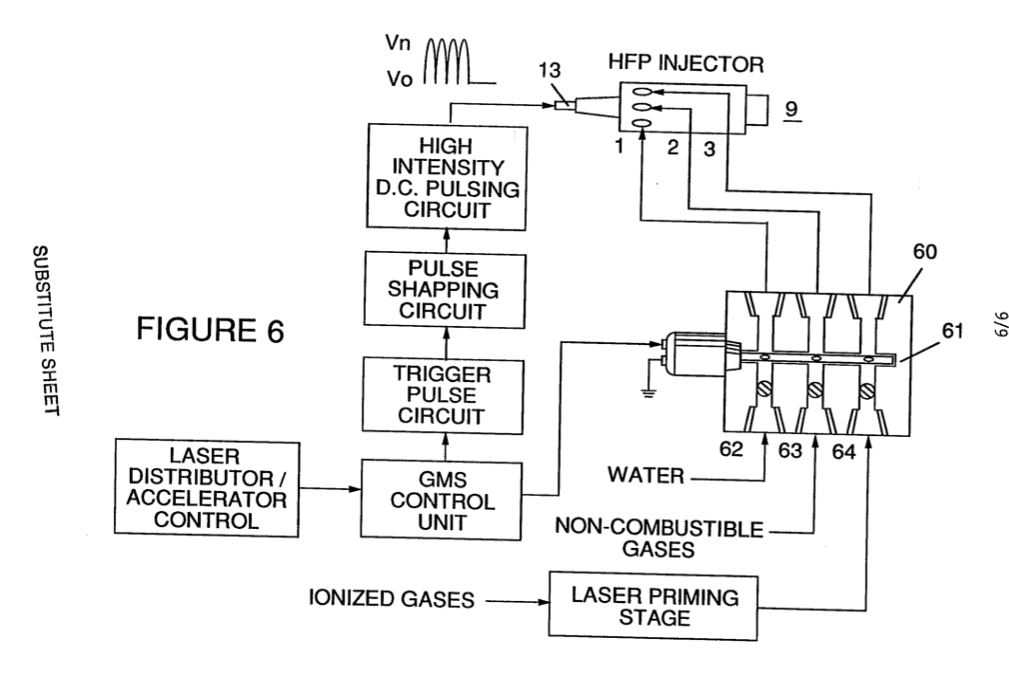

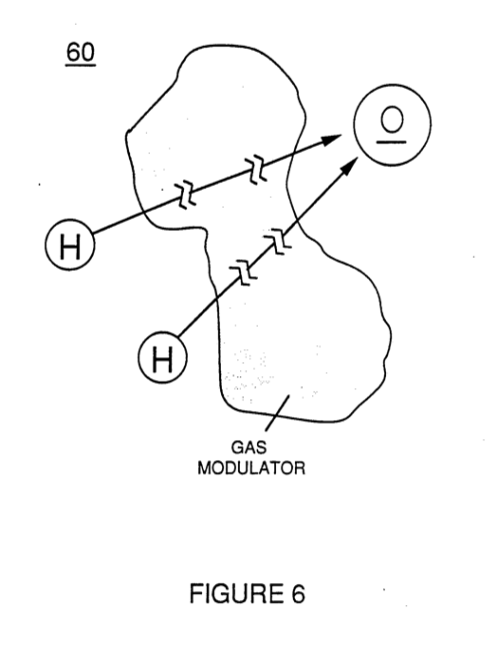

Figures 6, 7, 8 and 9 relate to pulsing control means including a gated pulse frequency generator (Figure 6): a phase lock circuit (Figure 7); a resonant scanning circuit (Figure 8); and the pulse indicator circuit (Figure 9) that control pulses transmitted to the resonant cavity/water fuel cell capacitor.

Figure 6: a phase lock circuit

Figure 6 - PLL Phase Lock Circuit

(Figure 7); a resonant scanning circuit

Figure 7 - Resonant Scanning Circuit

(Figure 8); and the pulse indicator circuit

Figure 8 - Pulse Indicator Circuit

(Figure 9): the pulse indicator circuit that control pulses transmitted to the resonant cavity/water fuel cell capacitor.

Figure 9 - PLL Feedback Circuit

Figure 10 shows the pulsing core and the voltage intensifier circuit that is the interface between the control circuit and the resonant cavity.

Figure 10 - VIC Interface

Figure 11 is a gas feedback control circuit.

Figure 11 - Gas Feedback Control Circuit

Figure 12 is an adjustable frequency generator circuit.

Figure 12 - Adjustable Frequency Generator Circuit

The circuits are operatively interconnected as shown in Figure 1 and to the pulsing core voltage intensifier circuit of Figure 10, which, inter alia, electrically isolates the water capacitor so that it becomes an electrically isolated cavity for the processing of water in accordance with its dielectric resonance properties. By reason of the isolation, power consumption in the control and driving circuits is minimized when resonance occurs; and current demand is minimized as voltage is maximized in the gas production mode of the water capacitor/fuel cell.

inter alia: (adverb) - among other things.

The reference letters appearing in the Figures, A, B, C, D, E, etc., to M and Ml show, with respect to each separate circuit depicted, the point at which a connection in that circuit is made to a companion or interrelated circuit.

In the invention, the water capacitor is subjected to a duty pulse which builds up in the resonant changing choke coil and then collapses. This occurrence permits a uni-polar pulse to be applied to the fuel cell capacitor. When a resonant condition of the circuit is locked-in by the circuit, amp leakage is held to a minimum as the voltage which creates the dielectric field tends to infinity. Thus, when high voltage is detected upon resonance, the phase lock loop circuit that controls the cell driver circuit maintains the resonance at the detected (or sensed) frequency.

The resonance of the water capacitor cell is affected by the volume of water in the cell. The resonance of any given volume of water maintained in the water capacitor cell is also affected by "contaminants" in the water which act as a damper. For example, at an applied potential difference of 2000 to 5000 volts to the cell, an amp spike or surge may be caused by inconsistencies in water characteristics that cause an out-of-resonance condition which is remedied instantaneously by the control circuits.

In the invention, the adjustable frequency generator (Figure 12) tunes into the resonant condition of the circuit including the water cell and the water therein. The generator has a frequency capability of 0 - 10 KHz and tunes into resonance typically at a frequency of 5 KHz in a typical 3.0 inch water capacitor formed of a 0.5 inch rod enclosed within a 0.75 inside diameter cylinder.

At start up, in this example, current draw through the water cell will measure about 25 milliamp; however, when the circuit finds a tuned resonant condition, current drops to a 1-2 milliamp minimum leakage condition.

The voltage to the capacitor water cell increases according to the turns of the winding and size of the coils, as in a typical transformer circuit. For example, if 12 volts are sent to the primary coil of the pulsing core and the secondary coil resonant charging choke ratio is 30 to 1, then 360 volts are sent to the capacitor water cell. Turns are a design variable that control the voltage of the uni-polar pulses sent to the capacitor.

High Speed Switching Diode

The high speed switching diode shown in Figure 10 prevents charge leakage from the charged water in the water capacitor cavity, and the water capacitor as an overall capacitor circuit element, i.e., the pulse and charge status of the water/capacitor never pass through an arbitrary ground. The pulse to the water capacitor is always uni-polar, The water capacitor is electrically isolated from the control, input and driver circuits by the electromagnetic coupling through the core. The switching diode in the VIC circuit (Figure 10) performs several functions in the pulsing. The diode is an electronic switch that determines the generation and collapse of an electromagnetic field to permit the resonant charging choke(s) to double the applied frequency and also allows the pulse to be sent to the resonant cavity without discharging the "capacitor" therein. The diode, of course, is selected in accordance with the maximum voltage encountered in the pulsing circuit. A 600 PIV fast switching diode, such as an NVR 1550 high speed switching diode, has been found to be useful in the circuit herein,

The VIC circuit of Figure 10 also includes a ferromagnetic or ceramic ferromagnetic pulsing core capable of producing electromagnetic flux lines in response to an electrical pulse input. The flux lines equally affect the ‘secondary coil and the resonant charging choke windings. Preferably, the core is a closed loop construction. The effect of the core is to isolate the water capacitor and to prevent the pulsing signal from going below an arbitrary ground and to maintain the charge of the already charged water and water capacitor.

In the pulsing core, the coils are preferably wound in the same direction to maximize the additive effect of the electromagnetic field therein.

The magnetic field of the pulsing core is in synchronization with the pulse input to the primary coil. The potential from the secondary coil is introduced to the resonant charging choke({s) series circuit elements which are subjected to the same synchronous applied electromagnetic field, simultaneously with the primary pulse.

When resonance occurs, control of the gas output is achieved by varying voltage amplitude or varying the time of duty gate cycle. The transformer core is a pulse frequency doubler. In a figurative explanation of the workings of the fuel gas generator water capacitor cell, when a water molecule is “hit" by a pulse, electron time share is affected, and the molecule is charged. When the time of the duty cycle is changed, the number of pulses that “hit" the molecules in the fuel cell is correspondingly modified. More “hits" result in a greater rate of molecular disassociation.

With reference to the overall circuit of Figure 1, Figure 3 receives a digital input signal, and Figure 4 depicts the control means that directs 0-12 volts across the primary coil of the pulsing core. Depending upon design parameters of primary coil voltage and other Factors relevant to core design, the secondary coil of the pulsing core can be set up for a predetermined maximum, such as 2000 volts.

Figure 5, the cell driver circuit, allows a gated pulse to be varied in direct relation to voltage amplitude.

As noted above, the circuit of Figure 6 produces a gate pulse frequency. The gate pulse is superimposed over the resonant frequency pulse to create a duty cycle that determines the number of discrete pulses sent to the primary coil. For example, assuming a resonant pulse of 5 KHz, a 0.5 Hz gate pulse may be superimposed over the 5 KHz pulse to provide 2500 discrete pulses in a 50% duty cycle per Hz. The relationship of resonant pulse to the gate pulse is determined by conventional signal addition/subtraction techniques.

Figure 7, a phase lock loop, allows pulse frequency to be maintained at a predetermined resonant condition sensed by the circuit. Together, the circuits of Figures 7 and 8 determine an output signal to the pulsing core until the peak voltage signal sensed at resonance is achieved.

A resonant condition occurs when the pulse frequency and the voltage input attenuates the covalent bonding forces of the hydrogen and oxygen atoms of the water molecule. When this occurs, amp leakage through the water capacitor is minimized. The tendency of voltage to maximize at resonance increases the force of the electric potential applied to the water molecules, which ultimately disassociate into atoms.

Because resonances of different waters, water volumes, and capacitor cells vary, the resonant scanning circuit of Figure 8 is useful. The scanning circuit of Figure 8 scans frequency from high to low to high repeating until a signal lock is determined. The ferromagnetic core of the voltage intensifier circuit transformer suppresses electron surge in an out-of-resonance condition of the fuel cell. In an example, the circuit scans at frequencies from 0 Hz to 10 KHz to 0 Hz. In water having contaminants in the range of 1 ppm to 20 ppm, a 20% variance in resonant frequency is encountered. Depending on water flow rate into fuel cell, the normal variance range is about 8-10%. For example, iron in well water affects the status of molecular disassociation. Also, at a resonant condition harmonic effects occur. In a typical operation of the cell with a representative water capacitor described below, at a frequency of about 5 KHz at unipolar pulses from 0 to 650 volts at a sensed resonant condition into the resonant cavity, conversion of’ about 5 gallons of water per hour into a fuel gas will occur on average. To increase the rate, multiple resonant cavities can be used and/or the surfaces of the water capacitor can be increased, however, the water capacitor cell is preferably small in scale. A typical water capacitor may be formed from a 0.5 inch in diameter stainless steel rod and a 0.75 inch inside diameter cylinder that together extend concentrically about 3.0 inches with respect to each other.

Shape and size of the resonant Cavity may vary. Larger resonant cavities and higher rates of consumption of water in the conversion process require higher frequencies such as up to 50 KHz and above. The pulsing rate, to sustain such high rates of conversion must be correspondingly increased.

From the foregoing description of the preferred embodiment, other variations and modifications of the system disclosed will be evident to those of skill in the art.

WHAT IS CLAIMED IS:

- A control circuit for a resonant cavity water capacitor cell utilized for the production of a hydrogen containing fuel gas including an isolation transformer including a ferromagnetic core and having one side of a secondary coil connected in series with a high speed switching diode to one plate of the water capacitor of the resonant cavity and the other side of the secondary coil connected to the other plate of the water capacitor to form a closed loop electronic circuit utilizing the dielectric properties of water as part of the electronic circuit and a primary coil connected to a pulse generation means.

- The circuit of Claim 1 in which the secondary coil includes segments that form a resonant charging choke circuit in series with the water capacitor.

- The circuit of Claim 1 in which the pulse generation means includes an adjustable first frequency generator and a second gated pulse frequency generator which controls the number of pulses produced by the first frequency generator sent to the primary coil during a period determined by the gate frequency of the second pulse generator.

- The circuit of Claim 1 further including a means for sensing the occurrence of a resonant condition in the water capacitor of the resonant cavity.

- The circuit of Claim 4 in which the means for sensing is a pickup coil on the ferromagnetic core of the transformer.

- The circuit of Claim 4 or Claim 5 in which the sensing means is interconnected to a scanning circuit and a phase lock loop circuit, whereby the pulsing frequency to the primary coil of the transformer is maintained at a sensed frequency corresponding to a resonant condition in the water capacitor.

- The circuit of Claim 1 including means for adjusting the amplitude of a pulsing cycle sent to the primary coil.

- The circuit of Claim 6 including further means for maintaining the frequency of the pulsing cycle at a constant frequency regardless of pulse amplitude.

- The circuit of Claim 3 in which the gated pulse frequency generator is operatively interconnected with a sensor that monitors the rate of gas production from the cell and controls the number of pulses to the cell in a gated frequency in a correspondence with the rate of gas production.

- The circuit of Claim 7 or Claim 8 or Claim 9 further including a gas pressure sensor in an enclosed water capacitor resonant cavity which also includes a gas outlet, which gas pressure sensor is operatively connected to the circuit to determine the rate of gas production with respect to ambient gas pressure in the water capacitor enclosure.

- The methods and apparatus as substantially described herein.

WO8912704A1 - Process And Apparatus For The Production Of Fuel Gas And The Enhanced Release Of Thermal Energy From Such Gas

PDF Download: SMeyer-WO8912704A1-Process_&_Apparatus_for_The_Production_of_Fuel_Gas_&_Enhanced_Release_of_Thermal_Energy.pdf

Abstract

Water molecules are broken down into hydrogen and oxygen gas atoms in a capacitive cell by a polarization and resonance process dependent upon the dielectric properties of water and water molecules. The gas atoms are thereafter ionized or otherwise energized and 8 thermally combusted to release a degree of energy greater than that of combustion of the gas in ambient air.

WO8912704A1 - Process And Apparatus For The Production Of Fuel Gas And The Enhanced Release Of Thermal Energy From Such Gas

Related Applications

This is a continuation-in-part of my co-pending application Serial Wo. 207,730 filed June 16, 1988 which in turn was a continuation in part of Serial No. 081,859, now United States Patent No. 4, 826, 581.

Field of the Invention

This invention relates to a method of and apparatus for obtaining the release of a fuel gas mixture including hydrogen and oxygen from water and to a method of and apparatus for obtaining the further release of energy from such a fuel gas mixture. Charged ions derived from the fuel gas are stimulated to an activated state, and then passed through a resonant cavity, where successively increasing energy levels are achieved, and finally passed to an outlet orifice to produce thermal explosive energy.

Background of the Prior Art

Numerous processes have been proposed for separating a water molecule into its elemental hydrogen and oxygen components. Electrolysis is one such process. Other processes are described in United States patents such as 4,344,831; 4,184,931; 4,023,545; 3,980,053; and Patent Cooperation Treaty Application No. PCT/US80/1362, published 30 April, 1981.

Other processes have been proposed for many years in which controlled energy producing reactions of atomic particles are expected to occur under "cold" conditions.

Source: ([See, e.g,. Rafelski, J. and Jones, S.E., "Cold Nuclear Fusion," Scientific American, July, 1987, page 84].

Further processes are also described in United States patents 4,233,109; 4,406,765; 4,687,753 and 4,695,357. The process and apparatus described herein are considered variations to and improvements in fuel sources and processes by which energy is derived from fuel gas components in a controllable manner.

Objects of the Invention

A first object of the invention is to provide a fuel cell and a process in which molecules of water are broken down into hydrogen and oxygen gases, and a fuel gas mixture including hydrogen, oxygen and other gasses formerly dissolved within the water is produced. A further object of the invention is to realize significant energy-yield from a fuel gas derived from water (H20) molecules. Molecules of water are broken down into hydrogen and oxygen gases. Electrically charged hydrogen and oxygen ions of opposite electrical polarity are activated by electromagnetic wave energy and exposed to a high temperature thermal zone. Significant amounts of thermal energy with explosive force beyond the gas burning stage are released.

An explosive thermal energy under a controlled state is produced. The process and apparatus provide a heat energy source useful for power generation, aircraft, rocket engines, or space stations.

Brief Description of the Drawings

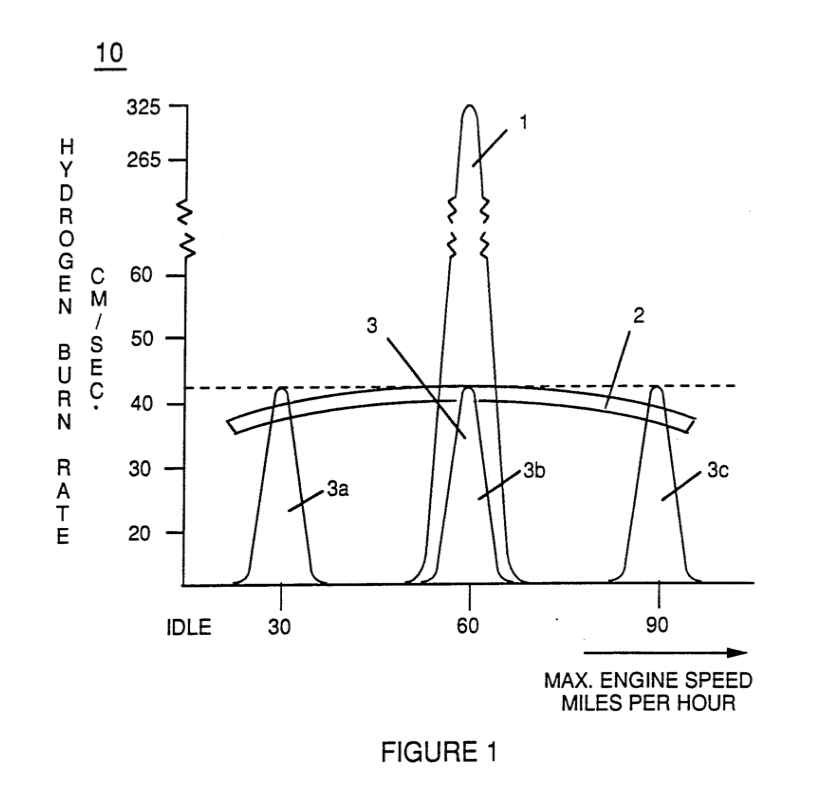

Figures 1A through 1F

Figures 1A through 1F are illustrations depicting the theoretical bases for phenomena encountered during operation of the fuel gas production stage of the invention herein

Figure 2 illustrates a circuit useful in the fuel gas generation process

Figure 2 - Useful Circuit

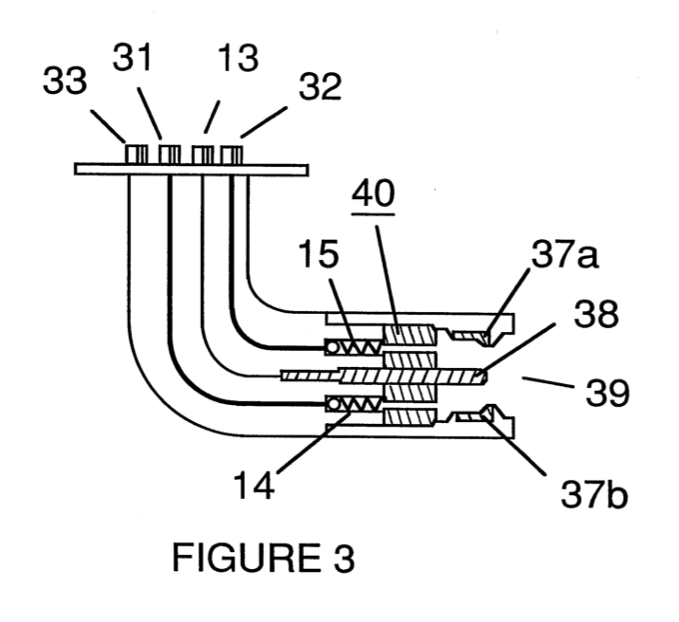

Figure 3 shows a perspective of a “water capacitor" element used in the fuel cell circuit.

Figure 3 - Perspective Water Capacitor Element

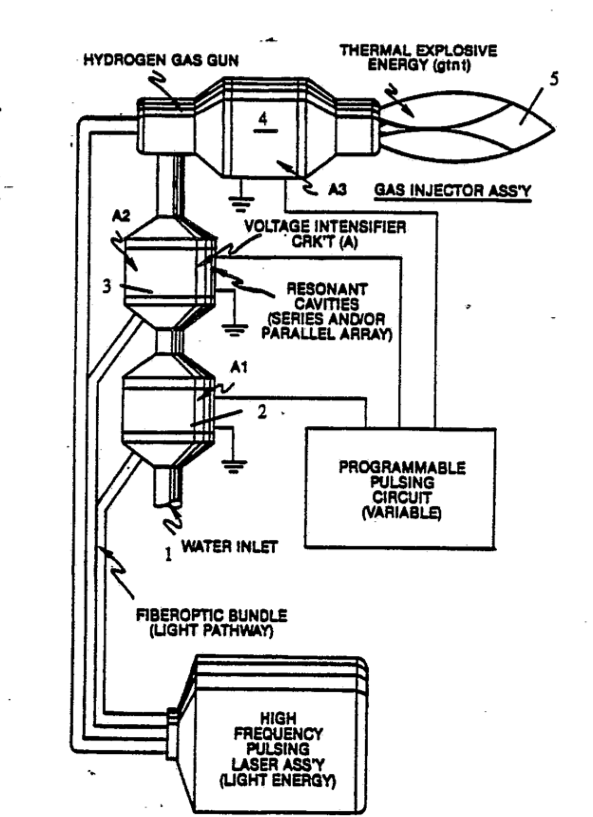

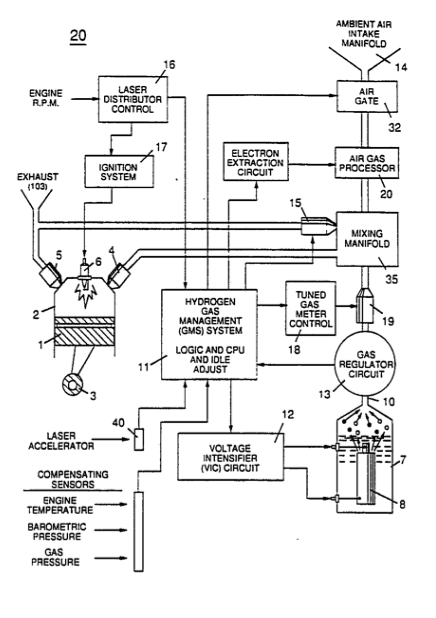

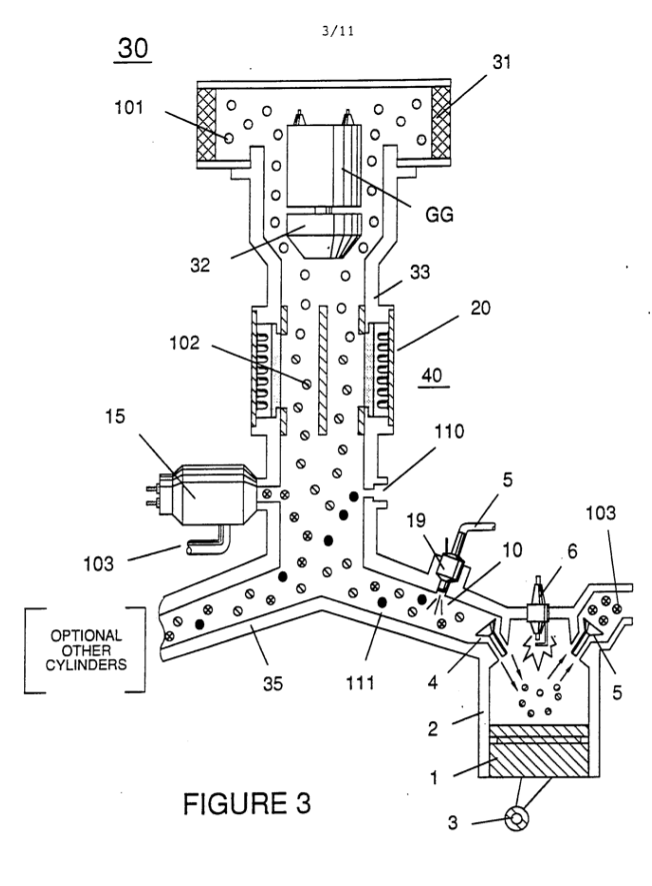

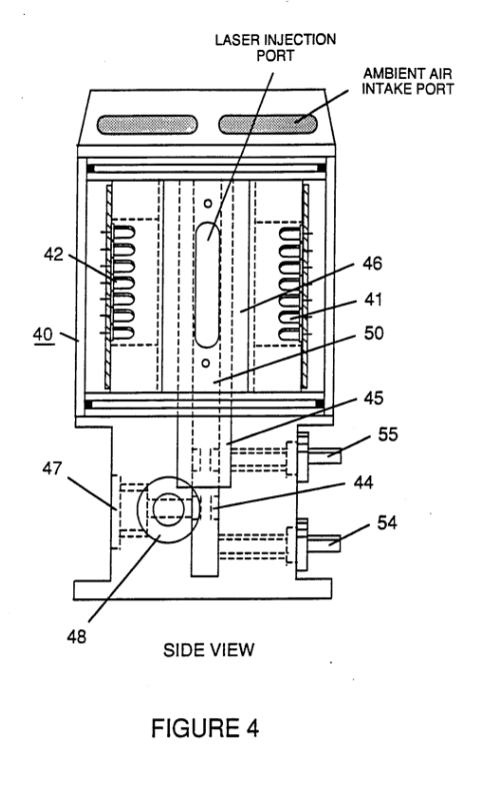

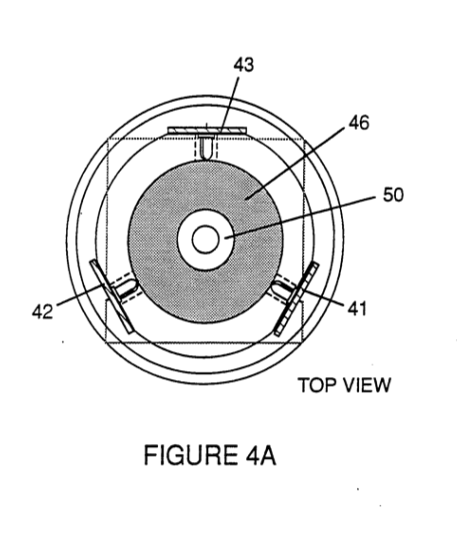

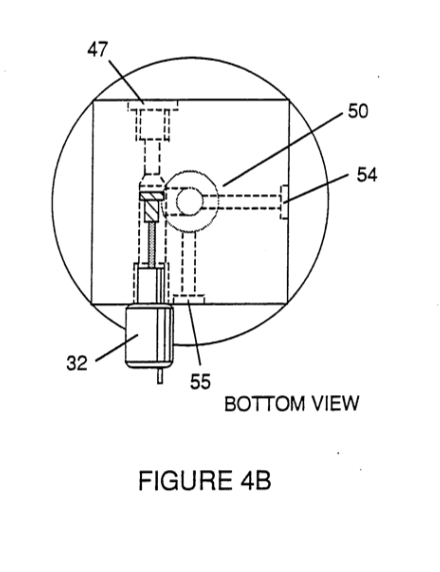

Figure 4 illustrates a staged arrangement of apparatus useful in the process, beginning with a water inlet and culminating in the production of thermal explosive energy.

Figure 4 - Staged Arrangement of Apparatus

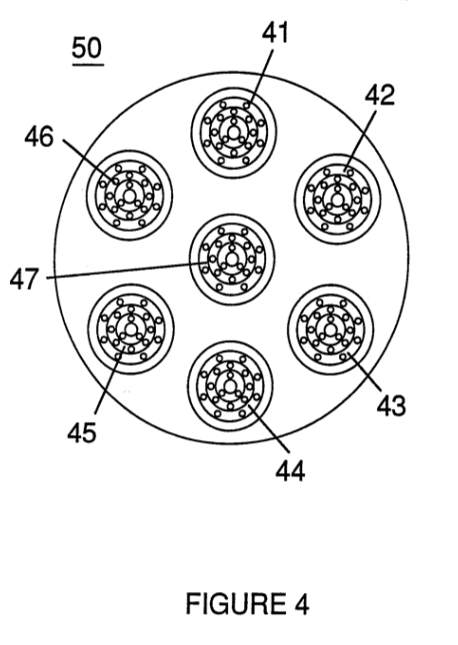

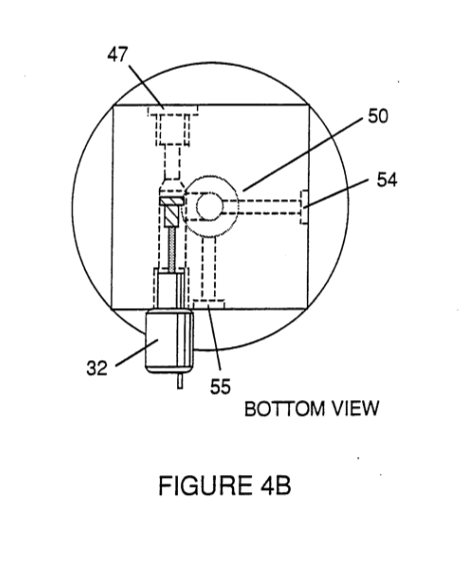

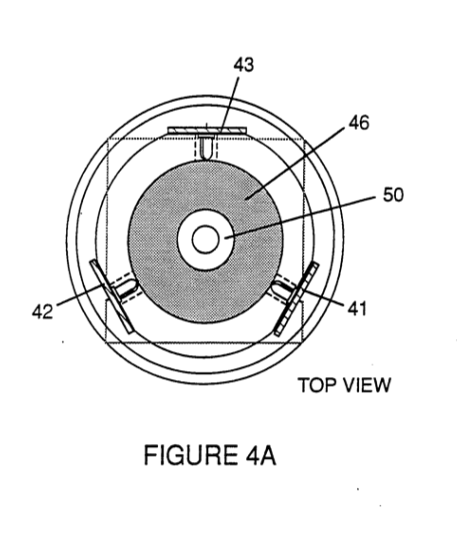

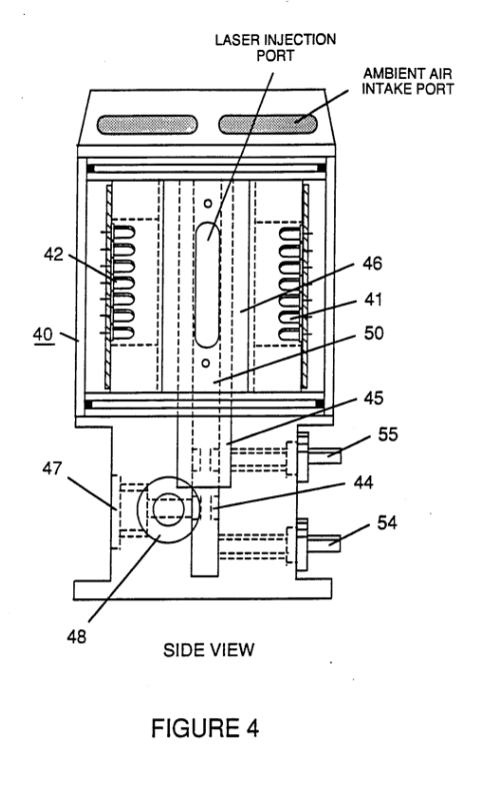

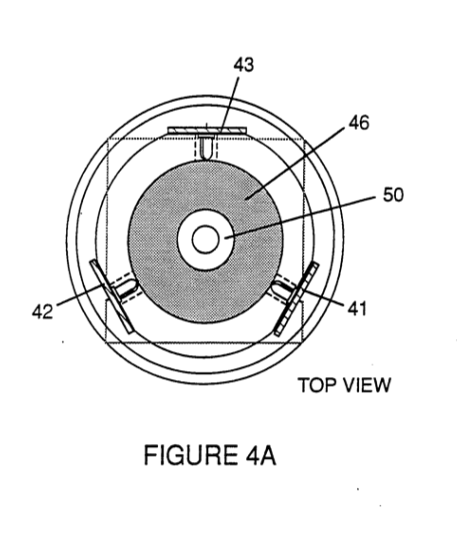

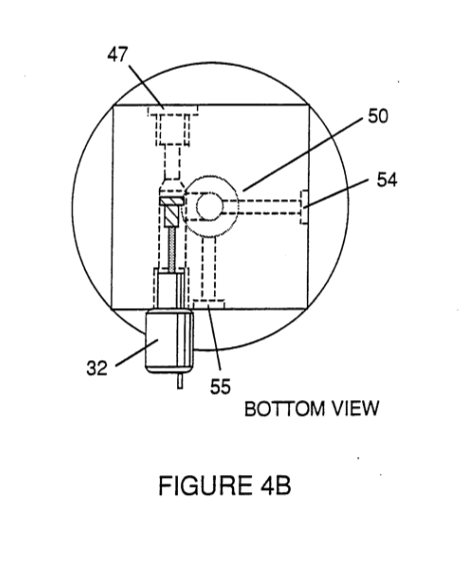

Figure 5A shows a cross-section of a circular gas resonant cavity used in the final stage assembly of Figure 4.

Figure 5A - Gas Cavity Cross-Section

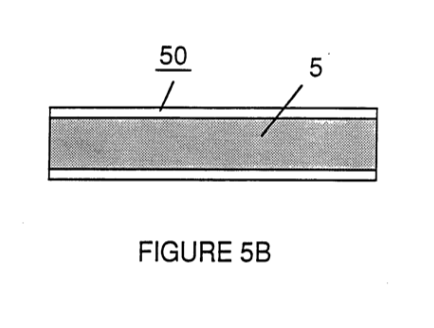

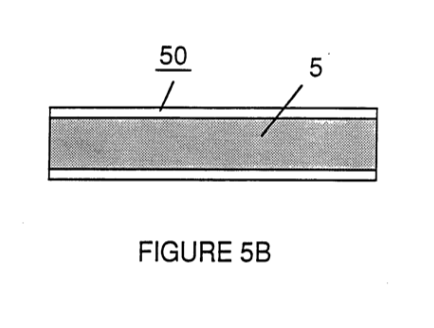

Figure 5B shows an alternative final stage injection system useful in the apparatus of Figure 4.

Figure 5B - Alternative Final Stage Injection System

Figure 5C shows an optical thermal lens assembly for use with either final stage of Figure 5A or Figure 53.

Figure 5C - Optical Thermal Lens Assembly

Figures 6A, 6B, 6C and 6D are illustrations depicting various theoretical bases for atomic phenomena expected to occur during operation of the invention herein.

Figures 6A, 6B, 6C and 6D - Various Theoretical Bases for Atomic Phenomena

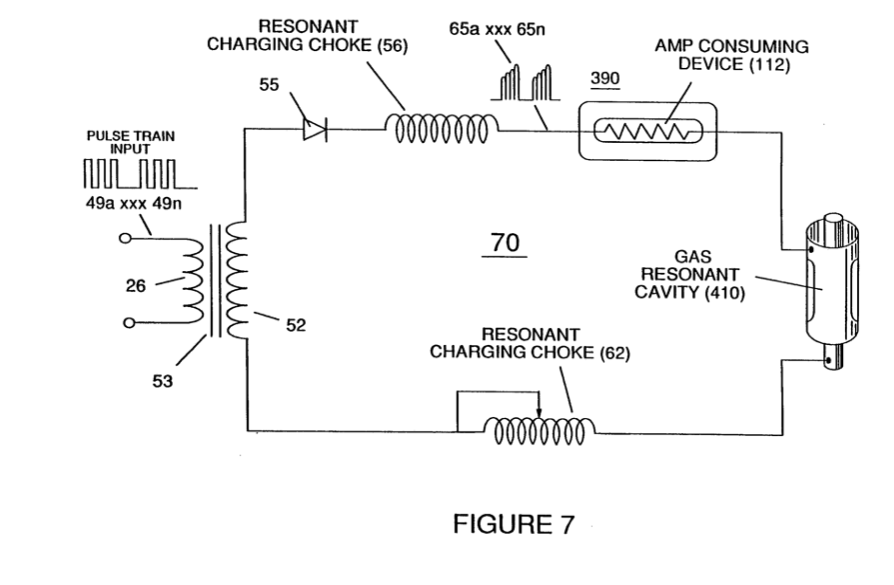

Figure 7 is an electrical schematic of the voltage source for the Base resonant cavity.

Figure 7 - Base Voltage Source

Figures 8A and 8B, respectively, show (A) an electron extractor grid used in the injector assemblies of Figure 5A and Figure 5B, and (B) the electronic control circuit for the extractor grid.

Figures 8A and 8B - Electron Extraction Grid & Control Circuit

Figure 9 shows an alternate electrical circuit useful in providing a pulsating waveform to the apparatus.

Figure 9 - Alternate Pulse Waveform Circuit

Description of the Preferred Embodiment

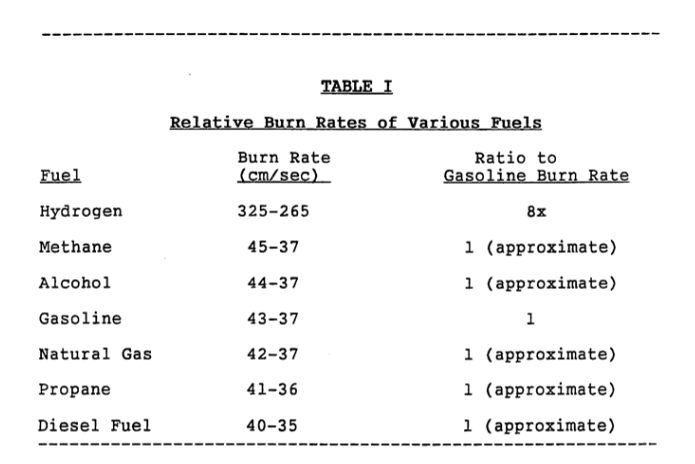

A fuel gas is produced by a hydrogen fracturing process that follows the sequence of steps shown in the following Table I.

Beginning with water molecules, the molecule is subjected to successively increasing electrical wave energy and thermal forces. In the succession of forces, randomly oriented water molecules are aligned with respect to molecular polar orientation and are themselves polarized and “elongated” by the application of an electric potential to the extent that covalent bonding of the water molecule is so weakened that the atoms disassociate and the molecule breaks down into hydrogen and oxygen elemental components. The released atomic gases are next ionized and electrically charged in a vessel while being subjected to a further energy source that promotes inter-particle impact in the gas at an increased overall energy level. Finally, the atomic particles in the excited gas, having achieved successively higher energy levels, are subjected to a laser or electromagnetic wave energy source that produces atomic destabilization and the final release of thermal explosive energy. Engineering design parameters based on known theoretical principles of atomic physics determine the incremental levels of electrical and wave energy input required to produce resonance in each stage of the system. Instead of a dampening effect, a resonant energization of the molecule, atom or ion provides a compounding energy interaction resulting in the final energy release.

TABLE 1

PROCESS STEPS LEADING TO IGNITION

RELATIVE STATE OF WATER MOLECULE AND/OR HYDROGEN/OXYGEN/OTHER ATOMS

1st Stage Water to Gas

- RANDOM (AMBIENT STATE)

- ALIGNMENT OF POLAR FIELDS

- POLARIZATION OF MOLECULES

- MOLECULAR ELONGATION

- ATOM LIBERATION BY BREAKDOWN OF COVALENT BOND

- RELEASE OF GASES

2nd Stage Gas Ionization

- LIQUID TO GAS IONIZATION ELECTRICAL CHARGING EFFECT PARTICLE IMPACT

- ELECTROMAGNETIC WAVE, LASER OR PHOTON INJECTION

3rd Stage Priming

- ELECTRON EXTRACTION ATOMIC DESTABILIZATION

Final Stage Ignition

- THERMAL IGNITION

In brief, in the first stage a gas mixture including hydrogen and oxygen and other dissolved gases formerly entrapped in water is obtained, from water.

In general, the method used in the first stage consists of:

(A) providing a capacitor, in which the water is included as a dielectric liquid between capacitor plates, in a resonant charging choke circuit that includes an inductance in series with the capacitor;

(B) subjecting the capacitor to a pulsating, unipolar electric voltage field in which the polarity does not pass beyond an arbitrary ground, whereby the water molecules within the capacitor are subjected to a charge of the same polarity and the water molecules are distended by their subjection to electrical polar forces;

(C) further subjecting the water in said capacitor to said pulsating electric field to achieve a pulse frequency such that the pulsating electric field induces a resonance within the water molecule;

(D) continuing the application of the pulsing frequency to the capacitor cell after resonance occurs so that the energy level within the molecule is increased in cascading incremental steps in proportion to the number of pulses;

(E) maintaining the charge of said capacitor during the application of the pulsing field, whereby the covalent electrical bonding of the hydrogen and oxygen atoms within said molecules is destabilized such that the force of the electrical field applied, as the force is effective within the molecule, exceeds the bonding force of the molecule, and hydrogen and oxygen atoms are liberated from the molecule as elemental gases; and

(F) collecting said hydrogen and oxygen gases, and any other gases that were formerly dissolved within the water, and discharging the collected gases as a fuel gas mixture.

The water molecules are subjected to ‘increasing electrical forces. In an ambient state, randomly oriented water molecules are aligned with respect to a molecular polar orientation. They are next, themselves polarized and “elongated" by the application of an electric potential to the extent that covalent bonding of the water molecule is so weakened that the atoms disassociate and the molecule breaks down into hydrogen and oxygen elemental components.

In the process, the point of optimum gas release is reached at a circuit resonance.

Water in the fuel cell is subjected to a pulsating, polar electric field produced by the electrical circuit whereby the water molecules are distended by reason of their subjection to electrical polar forces of the capacitor plates. The polar pulsating frequency applied is such that the pulsating electric field induces a resonance in the molecule. A cascade effect occurs and the overall energy level of specific water molecules is increased in cascading, incremental steps. The hydrogen and oxygen atomic gases, and other gas components formerly entrapped as dissolved gases in water, are released when the resonant energy exceeds the covalent bonding force of the water molecule. A preferred construction material for the capacitor plates is a Stainless steel I-304 which is non-chemically reactive with water, hydrogen, or oxygen.

An electrically conductive material which is inert in the fluid environment is a desirable material of construction for the electrical field plates of the "water capacitor" employed in the circuit.

Once triggered, the gas output is controllable by the attenuation of operational parameters, Thus, once the frequency of resonance is identified, by varying the applied pulse voltage to the water fuel cell assembly, gas output is varied. By varying the pulse shape and/or amplitude or pulse train sequence of the initial pulsing wave source, final gas output is varied. Attenuation of the voltage field frequency in the form of OFF and ON pulses likewise affects output.

The overall apparatus thus includes an electrical circuit in which a water capacitor having a known dielectric property is an element. The fuel gases are obtained from the water by the disassociation of the water molecule. The water molecules are split into component atomic elements (hydrogen and oxygen gases) by a voltage stimulation process called the electrical polarization process which also releases dissolved gases entrapped in the water.

From the outline of physical phenomena associated with the first stage of the process described in Table 1, the theoretical basis of the invention considers the respective states of molecules and gases and ions derived from liquid water. Before voltage stimulation, water molecules are randomly dispersed throughout water within a container. When a uni-polar voltage pulse train such as shown in Figures 1B through 1F is applied to positive and negative capacitor plates, an increasing voltage potential is induced in the molecules in a linear, step-like charging effect. The electrical field of the particles within a volume of water including the electrical field plates increases from a low energy state to a high energy state successively in a step manner following each pulse-train as illustrated figuratively in the depictions of Figures 1A through 1F. The increasing voltage potential is always positive in direct relationship to negative ground potential during each pulse. The voltage polarity on the plates which create the voltage fields remains constant although the voltage charge increases. Positive and negative voltage “zones” are thus formed simultaneously in the electrical field of the capacitor plates.

In the first stage of the process described in Table 1, because the water molecule naturally exhibits opposite electrical fields in a relatively polar configuration (the two hydrogen atoms are positively electrically charged relative to the negative electrically charged oxygen atom), the voltage pulse causes initially randomly oriented water molecules in the liquid state to spin and orient themselves with reference to positive and negative poles of the voltage fields applied. The positive electrically charged hydrogen atoms of said water molecule are attracted to a negative voltage field; while, at the same time, the negative electrically charged oxygen atoms of the same water molecule are attracted to a positive voltage field. Even a slight potential difference applied to inert, conductive plates of a containment chamber which forms a capacitor will initiate polar atomic orientation within the water molecule based on polarity differences.

When the potential difference applied causes the orientated water molecules to align themselves between the conductive plates, pulsing causes the voltage field intensity to be increased in accordance with Figure 1B. As further molecular alignment occurs, molecular movement is hindered. Because the positively charged hydrogen atoms of said aligned molecules are attracted in a direction opposite to the negatively charged oxygen atoms, a polar charge alignment or distribution occurs within the molecules between said voltage zones, as shown in Figure 1B. And as the energy level of the atoms subjected to resonant pulsing increases, the stationary water molecules become elongated as shown in Figures 1C and 1D. Electrically charged nuclei and electrons are attracted toward opposite electrically charged voltage zones -- disrupting the mass and charge equilibrium of the water molecule.

Figures 1C and 1D - Step Charging

As the water molecule is further exposed to an increasing potential difference resulting from the step charging of the capacitor, the electrical force of attraction of the atoms within the molecule to the capacitor plates of the chamber also increases in strength. As a result, the covalent bonding between atoms which form the molecule is weakened and ultimately terminated. The negatively charged electron is attracted toward the positively charged hydrogen atoms, while at the same time, the negatively charged oxygen atoms repel electrons.

In a more specific explanation of the "sub-atomic" action that occurs in the water cell that provides a fuel gas for the subsequent stages, it is known that natural water is a liquid which has a dielectric constant of 78.54 at 20°C and 1 atm pressure.

Source: [Handbook of Chemistry and Physics, 68th ed., CRC Press (Boca Raton, Florida (1987-88)), Section E-50, H20 (water)].

When a volume of water is isolated and electrically conductive plates, that are chemically inert in water and are separated by a distance, are immersed in the water, a capacitor is formed, having a capacitance determined by the surface area of the plates, the distance of their separation and the dielectric constant of water.

When water molecules are exposed to voltage at a restricted current, water takes on an electrical charge. By the laws of electrical attraction, molecules align according to positive and negative polarity fields of the molecule and the alignment field. The plates of a capacitor constitute such an alignment field when a voltage is applied.

When a charge is applied to a capacitor, the electrical charge of the capacitor equals the applied voltage charge; in a water capacitor, the dielectric property of water resists the flow of amps in the circuit, and the water molecule itself, because it has polarity fields formed by the relationship of hydrogen and oxygen in the covalent bond, and an intrinsic dielectric property, becomes part of the electrical circuit, analogous to a "micro-capacitor" within the capacitor defined by the plates.

In the Example of a fuel cell circuit of Figure 2, a water capacitor is included. The step-up coil is formed on a conventional torroidal core formed of a compressed ferromagnetic powdered material that will not itself become permanently magnetized, such as the trademarked "Ferramic 06# "Permag" powder as described in Siemens Ferrites Catalog, CG~2000-002-121, (Cleveland, Ohio) No. F626-1205. The core is 1.50 inch in diameter and .25 inch in thickness. A primary coil of 200 turns of ~6-gauge copper wire is provided and a coil of 600 turns of 36 gauge wire comprises the secondary winding. Other primary/secondary coil winding ratios may be conventionally determined.

An alternate coil arrangement using a conventional M27 iron transformer core is shown in Figure 9. The coil wrap is always in one direction only.

In the circuit of Figure 2, the diode is a 1N1198 diode which acts as a blocking diode and an electric switch that allows voltage flow in one direction: only. Thus, the capacitor is never subjected to a pulse of reverse polarity.

The primary coil of the toroid is subject to a 50% duty cycle pulse. The toroidal pulsing coil provides a voltage step-up from the pulse generator in excess of five times, although the relative amount of step-up is determined by pre-selected criteria for a particular application. As the stepped-up pulse enters first inductor (formed from 100 turns of 24 gauge wire 1 inch in diameter), an electromagnetic field is formed around the inductor, voltage is switched off when the pulse ends, and the field collapses and produces another pulse of the same polarity; i.e., another positive pulse is formed where the 50% duty cycle was terminated. Thus, a double pulse frequency is produced; however, in a pulse train of uni-polar pulses, there is a brief time when pulses are not. present.

By being so subjected to electrical pulses in the circuit of Figure 2, water confined in the volume that includes the capacitor plates takes on an electrical charge that is increased by a step charging phenomenon occurring in the water capacitor.

Voltage continually increases (to about 1000 volts and more) and the water molecule starts to elongate.

The pulse train is then switched off: the voltage across the water capacitor drops to the amount of charge that the water molecules have taken on, i.e. voltage is maintained across the charged capacitor. The pulse train is then reapplied.

Because a voltage potential applied to a capacitor can perform work, the higher the voltage potential, the more work is performed by a given capacitor. In an optimum capacitor that is wholly non-conductive, zero (0) current flow will occur across the capacitor. Thus, in view of an idealized capacitor circuit, the object of the water capacitor circuit is to prevent electron flow through the circuit, i.e. such as occurs by electron flow or leakage through a resistive element that produces heat. Electrical leakage in water will occur, however, because of some residual conductivity and impurities or ions that may be otherwise present in the water. Thus, the water capacitor is preferably chemically inert. An electrolyte is not added to the water.

In the isolated water bath, the water molecule takes on charge, and the charge increases. The object of the process is to switch off the covalent bonding of the water molecule and interrupt the sub-atomic force, i.e, the electrical force or electromagnetic force, that binds the hydrogen and oxygen atoms to form a molecule so that the hydrogen and oxygen separate.

Because an electron will only occupy a certain electron shell (the shells are well known) the voltage applied to the capacitor affects the electrical forces inherent in the covalent bond. As a result of the charge applied by the plates, the applied force becomes greater than the force of the covalent bonds between the atom of the water molecule; and the water molecule becomes elongated. When this happens, the time share ratio of the electrons between the atoms and the electron shells is modified.

In the process, electrons are extracted from the water bath; electrons are not consumed nor are electrons introduced into the water bath by the circuit as electrons are conventionally introduced in an electrolysis process. There may nevertheless occur a leakage current through the water. Those hydrogen atoms missing electrons become neutralized; and atoms are liberated from the water. The charged atoms and electrons are attracted to opposite polarity voltage zones created between the capacitor plates. The electrons formerly shared by atoms in the water covalent bond are re-allocated such that neutral elemental gases are liberated.

In the process, the electrical resonance may be reached at all levels of voltage potential. The overall circuit is characterized as a "resonant charging choke" circuit which is an inductor in series with a capacitor that produces a resonant circuit.

Source: [SAMS Modern Dictionary of Electronics, Rudolff Garff, ©1984, Howard W. Sams & Co. (Indianapolis, Ind.)}, page 859.]

Such a resonant charging choke is on each side of the capacitor. In the circuit, the diode acts as a switch that allows the magnetic field produced in the inductor to collapse, thereby doubling the pulse frequency and preventing the capacitor from discharging. In this Manner a continuous voltage is produced across the capacitor plates in the water bath; and the capacitor does not discharge. The water molecules are thus subjected to a continuously charged field until the breakdown of the covalent bond occurs,

As noted initially, the capacitance depends on the dielectric properties of the water and the size and separation of the conductive elements forming the water capacitor.

EXAMPLE I

In an example of the circuit of Figure 2 (in which other circuit element specifications are provided above), two concentric cylinders 4 inches long formed the water capacitor of the fuel cell in the volume of water. The outside cylinder was 0.75 inch in outside diameter; the inner cylinder was 0.5 inch in outside diameter. Spacing from the outside of the inner cylinder to the inner surface of the outside cylinder was .0625 inch. Resonance in the circuit was achieved at a 26 volt applied pulse to the primary coil of the toroid at 10KHz, and the water molecules disassociated into elemental hydrogen and oxygen and the gas released from the fuel cell comprised a mixture of hydrogen, oxygen from the water molecule, and gases formerly dissolved in the water such as the atmospheric gases or oxygen, nitrogen, and argon. In achieving resonance in any circuit, as the pulse frequency is adjusted, the flow of amps is minimized and voltage is maximized to a peak. Calculation of the resonance frequency of an overall circuit is determined by known means; different cavities have a different frequency of resonance dependent on parameters of the water dielectric, plate size, configuration and distance, circuit inductors, and the like. Control of the production of fuel gas is determined by variation of the period of time between a train of pulses, pulse amplitude and capacitor plate size and configuration, with corresponding value adjustments to other circuit components.

The wiper arm on the second inductor tunes the circuit and accommodates to contaminants in water so that the charge is always applied to the capacitor. The voltage applied determines the rate of breakdown of the molecule into its atomic components. As water in the cell is consumed, it is replaced by any appropriate means or control system.

Thus in the first stage, which is of itself independently useful, a fuel gas mixture is produced having, in general, the components of elemental hydrogen and oxygen as well as formerly dissolved entrapped atmospheric gases such as nitrogen, argon, and the like. The fuel gas is itself combustible in a conventional manner. .

After the first stage the gas atoms become elongated during electron removal as the atoms are ionized. Laser, or light wave energy of a predetermined frequency is injected into a containment vessel in a gas ionization process. The light energy absorbed by voltage stimulated gas nuclei causes destabilization of gas ions still further. The absorbed laser energy causes the gas nuclei to increase in energy state, which, in turn, causes electron deflection to a higher orbital shell.

The electrically charged and laser primed combustible gas ions from a gas resonant cavity may be directed into an optical thermal liens assembly for triggering. Before entry into the optimal thermal lens, however, electrons are stripped from the ions and the atom is destabilized. The destabilized gas ions which are electrically and mass unbalanced atoms having highly energized nuclei are pressurized during spark ignition. The unbalanced, destabilized atomic components thermally interact; the energized and unstable hydrogen gas nuclei collide with highly energized and unstable oxygen gas nuclei, causing and producing thermal explosive energy beyond the gas burning Stage. The ambient air gas components in the initial mixture aid the thermal explosive process under a controlled state,

In the process, the point of optimum energy-yield is reached when the electron deficient oxygen atoms (having less than a normal number of electrons) lock onto and capture a hydrogen atom electron prior to or during thermal combustion of the hydrogen/oxygen mixture, Atomic decay results in the release of energy.

After the first stage, the gas mixture is subjected to a pulsating, polar electric field whereby electrons of the gas atoms are distended in their orbital fields by reason of their subjection to electrical polar forces. The polar pulsating frequency applied is such that the pulsating electric field induces a resonance with respect to an electron of the gas atom. A cascade effect results and the energy level of. specific resonating electron is increased in cascading, incremental steps.

Next, the gas atoms are ionized and subjected to electromagnetic wave energy having a predetermined frequency to induce a further election resonance in the ion, whereby the energy level of the election is successively increased. Electrons are extracted from the resonating ions while such ions are in an increased energy State to destabilize the nuclear electron configuration of said ions; and the gas mixture of destabilized ions is thermally ignited.

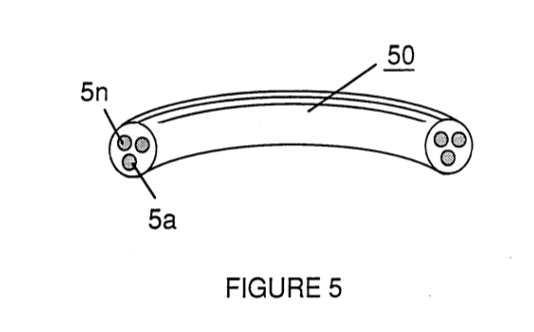

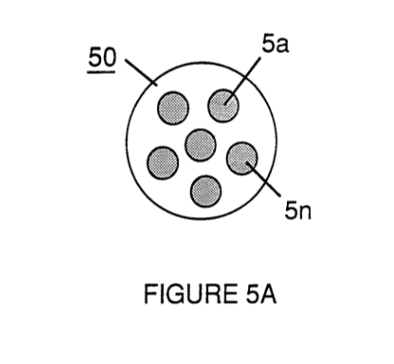

In the apparatus shown in Figure 4, water is introduced at inlet 1 into a first stage water fracturing module 2, such as the water fuel cell described above, in which water molecules are broken down into hydrogen, oxygen and released entrapped gas components. The released atomic gases and other gas components formerly entrapped as dissolved gases in water may be introduced to a successive stage 3 or other number of like resonant cavities, which are arranged in either a series or parallel combined array. The successive energization of the gas atoms provides a cascading effect, successively increasing the voltage stimulation level of the released gasses as they sequentially pass through cavities 2, 3, etc. Ina final stage, an injector system 4, of a configuration of the type show in Figures 5A or 5B, receives energized atomic and gas particles where the particles are subjected to further energy input, electrical excitation and thermal stimulation, whereby thermal explosive energy results 5, which may be directed thru a lens assembly of the type shown in Figure 5C to provide a controlled thermal energy output.

A single cell, or a battery of cells such as shown in Figure 3, provides a fuel gas source for stages after the first stage. The fuel gas is activated by electromagnetic waves, and electrically charged gas ions of hydrogen and oxygen (of opposite polarity) are expelled from the cascaded cells 2, 3, etc. shown in Figure 4. The circuit of Figure 9 may be utilized as a source of ionizing energy for the gases. The effect of cascading successively increases the voltage stimulation level of the released gases, which then are directed to the final injector assembly 4. In the injector assembly, gas ions are stimulated to a yet higher energy level. The gases are continually exposed to a pulsating laser or other electromagnetic wave energy source together with a high intensity oscillating voltage field that occurs within the cell between electrodes or conductive plates of opposite electrical polarity. A preferred construction material for the plates is a stainless steel T-304 which is non-chemically reactive with water, hydrogen, or oxygen. An electrically conductive material which is inert in the fluid environment is a desirable material of construction for the electrical field producing plates, through which field the gas stream of activated particles passes. Gas ions of opposite electrical charges reach and maintain a critical energy level state. The gas ions are oppositely electrically charged and subjected to oscillating voltage fields of opposite polarity and are also subjected to a pulsating electromagnetic wave energy source. Immediately after reaching critical energy, the excited gas ions are exposed to a high temperature thermal zone in the injection cell, 4, that causes the excited gas ions to undergo gas combustion. The gas ignition triggers atomic decay and releases thermal energy, 5, with explosive force.

Once triggered, the thermal explosive energy output is controllable by the attenuation of operational parameters. With reference to Figure 6A, for example, once the frequency of resonance is identified, by varying applied pulse voltage to the initial water fuel cell assemblies, 2, 3, the ultimate explosive energy output is likewise varied. By varying the pulse shape and/or amplitude or pulse train sequence of the electromagnetic wave energy source, final output is varied. Attenuation of the voltage field frequency in the form of OFF and ON pulses likewise affects output of the staged apparatus. Each control mechanism can be used separately, grouped in sections, or systematically arranged in a sequential manner.

A complete system in accordance with the present application thus includes a water fuel cell for providing a first fuel gas mixture consisting of at least a portion of hydrogen and oxygen gas. An electrical circuit of the type shown in Figure 7 provides a pulsating, polar electric field to the gas mixture as illustrated in Figure 6A, whereby electrons of the gas atoms are distended in their orbital fields by reason of their subjection to electrical polar forces, changing from the state conceptually illustrated by Figures 6B to that of Figure 6G, at a frequency such that the pulsating electric field induces a resonance with respect to electrons of the gas atoms. The energy level of the resonant electrons is thereby increased in cascading, incremental steps. A further electric field to ionize said gas atoms is applied and an electromagnetic wave energy source for subjecting the ionized gas atoms to wave energy of a predetermined frequency to induce a further electron resonance in the ion, whereby the energy level of the election is successively increased is an additional element of the apparatus as shown in Figure 6D.

An electron sink, which may be in the form of the grid element shown in Figure 8A, extracts further electrons from the resonating ions. While such ions are in an increased energy state and destabilizes the nuclear electron configuration of the ions. The "extraction" of electrons by the sink means is coordinated with the pulsating electrical field of the resonant cavity produced by the circuit of Figure 7, by means of an interconnected synchronization circuit, such as shown in Figure 8B. A nozzle, 10 in Figure 5B, or thermal lens assembly, Figure 5C, provides the directing means in which the destabilized ions are finally thermally ignited.

As previously noted, to reach and trigger the ultimate atomic decay of the fuel cell gases at the final stage, sequential steps are taken, First, water molecules are split into component atomic elements (hydrogen and oxygen gases) by a voltage stimulation process which also releases dissolved gases entrapped in the water. In the injector assembly, a laser produced light wave or other form of coherent electromagnetic wave energy capable of stimulating a resonance within the atomic components is absorbed by the mixture of gases (hydrogen/oxygen/ambient air gases) released by the polarization process. At this point, as shown in Figure 6B, the individual atoms are subjected to an electric field to begin an ionization process.

The laser or electromagnetic wave energy is absorbed and causes gas atoms to lose electrons and form positively charged gas ions. The energized hydrogen atoms which, as ionized, are positively charged, now accept electrons liberated from the heavier gases and attract other negatively charged gas ions as conceptually illustrated in Figure 6C. Positively and negatively charged gas ions are re-exposed to further pulsating energy sources to maintain random distribution of ionized atomic gas particles.

The gas ions within the wave energy chamber are subjected to an oscillating high intensity voltage field in a chamber 11 in Figures 5A and 5B formed within electrodes 12 and 13 in Figures 5A and 5B of opposite electrical polarity to produce a resonant cavity. The gas ions reach a critical energy state at a resonant state,

At this point, within the chamber, additional electrons are attracted to said positive electrode; whereas, positively charged ions or atomic nuclei are attracted to the negative electrode. The positive and negative attraction forces are co-ordinate and operate on said gas ions simultaneously; the attraction forces are non-reversible. The gas ions experience atomic component deflection approaching the point of electron Separation. At this point electrons are extracted from the chamber by a grid system such as shown in Figure 5A. The extracted electrons are consumed and prevented from re-entering the chamber by a circuit such as shown in Figure 8B. The elongated gas ions are subjected to a thermal heat zone to cause gas ignition, releasing thermal energy with explosive force. During ionic gas combustion, highly energized and stimulated atoms and atom nuclei collide and explode during thermal excitation. The hydrogen fracturing process occurring sustains and maintains a thermal zone, at a temperature in excess of normal hydrogen/oxygen combustion temperature, to wit, in excess of 2500°F. To cause and maintain atomic elongation depicted in Figure 6C before gas ignition, a voltage intensifier circuit such as shown in Figure 7 is utilized as a current restricting voltage source to provide the excitation voltage applied to the resonant cavity. At the same time the interconnected electron extractor circuit, Figure 8B, prevents the reintroduction of electrons back into the system. Depending on calculated design parameters, a predetermined voltage and frequency range may be designed for any particular application or physical configuration of the apparatus.

In the operation of the assembly, the pulse train source for the gas resonant cavity shown at 2 and 3 in Figure 4 may be derived from a circuit such as shown in Figures 2, 7 or 9, and such cavity circuits may be in sequence to provide a cascading energy input. It is necessary in the final electron extraction that the frequency with which electrons are removed from the system by sequenced and synchronized with the pulsing of the gas resonant cavity. In the circuit of Figure 8B, the coordination or synchronization of the circuit with the circuit of Figure 7 may be achieved by interconnecting point "A" of the gate circuit of Figure 8B to coordinate point "A" of the pulsing circuit of Figure 7.

The circuit shown in Figure 9 enhances the voltage potential across the resonant charging choke coils during puising operations and restricts amp flow by allowing an external electromagnetic pulsing field, F, derived from the primary coil A being energized to transverse the coil windings D and E being energized by the incoming pulse train Ha xxx Hn, through switching diode G, The external pulse field, F and the incoming pulse-train Ha xxx Hn, are sequentially the same, allowing resonant action to occur, restricting amp flow while allowing voltage intensity to increase to stimulate the electrical polarization process, the gas ionization process and the electron extraction process. The voltage intensifier circuit of Figure 9 prevents electrons from entering into those processes.

Together, the hydrogen injector assembly 4 and the resonant cavity assemblies 2, 3 form a gas injector fuel cell which is compact, light in weight and design variable. For example, the hydrogen injector system is suited for automobiles and jet engines. Industrial applications require larger systems. For rocket engine applications, the hydrogen gas injector system is positioned at the top of each resonant cavity arranged in a parallel cluster array. If resonant cavities are sequentially combined in a parallel/series array, the hydrogen injection assembly is positioned after the exits of said resonant cavities are combined.

From the outline of physical phenomena associated with the process described in Table 1, the theoretical basis of the invention considers the respective states of molecules, gases and ions derived from liquid water. Before voltage stimulation, water molecules are randomly dispersed throughout water within a container. When a uni-polar voltage pulse train such as shown in Figure 6A (53a xxx 53n) is applied, an increasing voltage potential is induced in the molecules, gases and/or ions in a linear, step-like charging effect. The electrical field of the particles within a chamber including the electrical field plates increases from a low energy state (A) to a high energy state (J) in a step manner following each pulse-train as illustrated in Figure 6A. The increasing voltage potential is always positive in direct relationship to negative ground potential during each pulse. The voltage polarity on the plates which create the voltage fields remains constant. Positive and negative voltage "zones" are thus formed simultaneously.

In the first stage of the process described in Table 1, because the water molecule naturally exhibits opposite electrical fields in a relatively polar configuration (the two hydrogen atoms are positively electrically charged relative to the negative electrically charged oxgen atom), the voltage pulse causes initially randomly oriented water molecules in the liquid state to spin and orient themselves with reference to positive and negative poles of the voltage fields applied. ‘The positive electrically charged hydrogen atoms of said water molecule are attracted to a negative voltage field; while, at the same time, the negative electrically charged oxygen atoms of the same water molecule are attracted to a positive voltage field. Even a slight potential difference applied to the inert, conductive plates of a containment chamber will initiate polar atomic orientation within the water molecule based on polarity differences,

When the potential difference applied causes the orientated water molecules to align themselves between the conductive plates, pulsing causes the voltage field intensity to be increased in accordance with Figure 6A. As further molecular alignment occurs, molecular movement is hindered, Because the positively charged hydrogen atoms of said aligned molecules are attracted in a direction opposite to the negatively charged oxygen atoms , a4 polar charge alignment or distribution occurs within the molecules between said voltage zones, as shown in Figure 6B. And as the energy level of the atoms subjected to resonant pulsing increases, the stationary water molecules become elongated as shown in Figure 6C. Electrically charged nuclei and electrons are attracted toward opposite electrically charged voltage zones ~— disrupting the mass equilibium of the water molecule.

In the first stage, as the water molecule is further exposed to a potential difference, the electrical force of attraction of the atoms within the molecule to the electrodes of the chamber also increases in intensity. As a result, the covalent bonding between said atoms which forms the molecule is weakened and ultimately terminated. The negatively charged electron is attracted toward the positively charged hydrogen atoms ’ while at the same time, the negatively charged oxygen atoms repel electrons,

Once the applied resonant energy caused by pulsation of the electrical field in the cavities reaches a threshold level, the disassociated water molecules, now in the form of liberated hydrogen, oxygen, and ambient air gases begin to ionize and lose or gain electrons during the final stage in the injector assembly. Atom destabilization occurs and the electrical and mass equilibrium of the atoms is disrupted. Again, the positive field produced within the chamber or cavity that encompasses the gas steam attracts negatively charged ions while the positively charged ions (and/or hydrogen nuclei) are attracted to the negative field. Atom stabilization does not occur because the pulsating voltage applied is repetitive without polarity change. A potential of approximately several thousand volts triggers the ionization state,

As the ionized particles accumulate within said chamber, the electrical charging effect is again an incremental stepping effect that produces an accumulative increased potential while, at the same time, resonance occurs.

The components of the atom begin to "vibrate" at a resonant frequency such that an atomic instability is created. As shown in Figure 6D, a high energy level is achieved, which then collapses resulting in the release of thermal explosive energy. Particle impact occurs when liberated ions in a gas are subjected to further voltage. A longitudinal cross section of a gas resonant cavity is shown in Figure 5A. To promote gas ionization, electromagnetic wave energy such as a laser or photon energy source of a predetermined wave length and pulse-intensity is directed to and absorbed by the ions forming said gas. In the device of Figure 5A, semiconductor optical lasers 20a-20p, 20xxx surround the gas flow path. In the device of Figure 5B, photon energy 20 is injected into a separate absorption chamber 21. The incremental stimulation of nuclei to a more highly energized state by electromagnetic wave energy causes electron deflection to a higher orbital state. The pulse rate as well as intensity of the electromagnetic wave source is varied to match the absorption rate of ionized particles to produce the stepped incremental increase in energy. A single laser coupled by means of fiber optic light guides is an alternative to the plurality of lasers shown in Figure 5B. Continued exposure of the gas ions to different forms of wave energy during voltage stimulation maintains individual atoms in a destabilized state and prevents atomic stabilization.

The highly energized gas ions are thermally ignited when said combustible gas ions pass from injector 4 and enter into and pass through a nozzle, 10 in Figure 5B, or an optical thermal lens assembly such as shown in Figure 5C, In Figure 5C, the combustible gas ions are expelled through and beyond a quenching circuit, 30, and reflected by lenses, 31 and 32, back and forth through a thermal heat zone, 33, prior to atomic breakdown beyond exiting through a final port, 34. A quenching circuit is a restricted orifice through which the particle stream passes such that flashback does not occur. The deflection shield or lens, 31, superheats beyond 3,000° F. and the combustible gas ions passing through said exiting-ports are regulated to allow a gas pressure to form inside said thermal zone. The energy yield is controlled by varying the applied voltage, or pulse-train since said thermal-lens assembly is self-adjusting to the flow-rate of said ionized and primed gases. The combustible ionic gas mixture is composed of hydrogen, oxygen, and ambient air gases. The hydrogen gas provides the thermal explosive force, the oxygen atoms aid the gas thermal ignition, and the ambient air gases retard the gas thermal ignition process to a controllable state. As the combustible gas mixture is exposed to a voltage pulse train, the stepped increasing voltage potential causes said moving gas atoms to become ionized (losing or gaining electrons) and changes the electrical and mass equilibrium of said atoms. Gases that do not wndergo the gas ionization process may accept the liberated electrons (electron entrapment) when exposed to light or photon stimulation. The electron extractor grid circuit, Figures 8A and 8B, is applied to the assembly of Figure 5A or Figure 5B, and restricts electron replacement. The extractor grid, 56, is applied adjacent to electric field producing members, 44 and 45, within the resonant cavity. The gas ions incrementally reach a critical-state which occurs after a high energy resonant state. At this point the atoms no longer tolerate the missing electrons, the unbalanced electrical field, and the energy stored in the nucleus. Immediate collapse of the system occurs and energy is released as the atoms decay into thermal explosive energy.

The repetitive application of a voltage pulse train (A through J of Figure 6A) incrementally achieves the critical state of said gas ions. As the gas atoms or ions (la xxx in) shown in Figure 6C become elongated during electron removal, electromagnetic wave energy of a predetermined frequency and intensity is injected. The wave energy absorbed by the stimulated gas nuclei and electrons causes further destabilization of the ionic gas. The absorbed energy from all sources causes the gas nuclei to increase in energy state, and induces the ejection of electrons from the nuclei,

To further stimulate the electron entrapment process beyond the atomic level (capturing the liberated electrons during the hydrogen fracturing process) the electron extractor grid (as shown in Figure 8A) is placed in spaced relationship to the gas resonant cavity structure shown in Figure 5A. The electron extractor grid is attached to an electrical circuit (such as shown in Figure 8B) that allows electrons to flow to an electrical load, 55, when a positive electrical potential is placed on the opposite side of said electrical load. The electrical load may be a typical power consuming device such as a light bulb or resistive heat. producing device. As the positive electrical potential is switched on or pulse-applied, the negative charged electrons liberated in the gas resonant cavity are drawn away and enter into resistive load where they are consumed and released as heat or light energy. The consuming electrical circuit can be directly connected to the gas resonant cavity positive electrical voltage zone. The incoming positive wave form applied to resonant cavity voltage zone through a blocking diode is synchronized with the pulse train applied to the gas resonant cavity by the circuit of Figure 7 via alternate gate circuit. As one pulse train is gated “ON,” the other pulse train is switched "OFF." A blocking diode directs the electron flow to said electrical load while resistive wire prevents voltage leakage during pulse train "ON" time.

The electron extraction process is maintained during gas flow-rate change by varying the trigger pulse rate in relationship to applied voltage. The electron extraction process also prevents spark-ignition of the combustible gases traveling through the gas resonant cavity because electron build-up and potential sparking is prevented.

In an optical thermal lens assembly or thrust-nozzle, such as shown in Figure 5C, destabilized gas ions (electrically and mass unbalanced gas atoms having highly energized nuclei) can he pressurized during spark-ignition, During thermal interaction, the highly energized and unstable hydrogen gas nuclei collide with the highly energized and unstable oxygen gas nuclei and produce thermal explosive energy beyond the gas burning stage. Other ambient air gases and ions not otherwise consumed limit the thermal explosive process.

Variations of the process and apparatus may be evident to those skilled in the art.

WHAT IS CLAIMED IS:

1. A method of obtaining the release of a gas mixture including hydrogen and other dissolved gases entrapped in water, from water, consisting of:

(A) providing a capacitor, in which the water is included as a dielectric between capacitor plates, in a resonant charging choke circuit that includes an inductance in series with the capacitor;

(B) subjecting the capacitor to a pulsating, uni-polar electric field in which the polarity does not pass beyond an arbitrary ground, whereby the water molecules within the capacitor are subjected to a charge of the same polarity;

(C) further subjecting the water in said capacitor to said pulsating electric field to achieve a pulse frequency such that the pulsating electric field induces a resonance within the water molecule;

(D) continuing the application of the pulsing frequency to the capacitor after resonance occurs so that the energy level within the molecule is increased in cascading incremental steps in proportion to the number of pulses;

(E) maintaining the charge of said capacitor during the application of the pulsing field, whereby the covalent electrical bonding of the hydrogen and oxygen atoms within said molecules is destabilized, such that the force of the electrical field applied within the molecule exceeds the bonding force of the molecule, and hydrogen and oxygen atoms are liberated from the molecule as elemental gases; and

(F) collecting said hydrogen and oxygen gases, and any other gases that were formerly dissolved within the water and discharging said collected gases as a fuel gas mixture.

2. The method of claim 1 including the further steps of:

(A) subjecting the collected gas mixture to a pulsating, polar electric field whereby electrons of the gas atoms are distended in their orbital fields by reason of their subjection to electrical polar forces, at a frequency such that the pulsating electric field induces a resonance with respect to an electron of the gas atom;

(B) cascading said gas atoms with respect to the pulsating electric field such that the energy level of the resonant electron is increased in cascading incremental steps;

(C) ionizing said gas atoms;

(D) subjecting the ionized gas atoms to electromagnetic wave energy having a predetermined frequency to induce a further election resonance in the ion, whereby the energy level of the electron is successively increased;

(E) extracting further electrons from the resonating ions while such ions are in an increased energy state to destabilize the nuclear and electron configuration of said ions; and

(F) subjecting the destabilized ions to thermal ignition, whereby thermal energy having a level enhanced over conventional combustion is achieved

3. In an apparatus for obtaining the release of a gas mixture including hydrogen and other dissolved gases entrapped in water, from water, the improvement consisting of a resonant electronic circuit in operative relationship with the water in which the dielectric property of water determines the resonance of the circuit.

4. The apparatus of Claim 3 in which the resonant circuit includes a resonant charging choke.

5. The apparatus of Claim 3 or Claim 4 in which water is included as a dielectric between conductive plates that form a capacitor in the resonant circuit.

6. An apparatus in accordance with Claim 3 or Claim 4 or Claim 5 further including successively interconnected:

(A) means for providing a pulsating, polar electric field to the gas mixture, whereby electrons of the gas atoms are- distended in their orbital fields by reason of their subjection to electrical polar forces, at a frequency such that the pulsating electric field induces a resonance with respect to an electron of the. gas atom; and the energy level of the resonant electron is increased in cascading, incremental steps; and

(B) means for providing a further electric field to ionize said gas atoms;

said further means connected to an electromagnetic wave energy source for subjecting the ionized gas atoms to wave energy of a predetermined frequency to induce a further election resonance in the ion, whereby the energy level of the electron is further successively increased; and

(C) an electron sink for extracting electrons from the resonating ions while such ions are in an increased energy state to destabilize the nuclear and electron configuration of said ions;

(D) a control means for directing particle flow in a continuous manner through the electric fields, wave energy source and electron sink to a final orifice at which the destabilized ions are thermally ignited; and

(E) a terminal orifice at which the mixture initially provided by the first means, after having passed through and been processed by the preceding means of the apparatus, is thermally ignited.

7. The method and apparatus as substantially described herein.

WO9222679A1 - Water Fuel Injection System

PDF Download: SMeyer-WO9222679A1-Water_Fuel_Injection_System.pdf

PCT WORLD INTELLECTUAL PROPERTY ORGANIZATION International Bureau

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

(51) International Patent Classification 5 : (11) International Publication Number: WO 92/22679 B Al oe te ete 51/00 (43) International Publication Date: © 23 December 1992 (23.12.92) (21) International Application Number: PCT/US91/03476 | Published

With international search report. (22) International Filing Date: 12 June 1991 (12.06.91)

(71}{(72) Applicant and Inventor: MEYER, Stanley, A. [US/US]; 3792 Broadway Blvd., Grove City, OH 43123 (US).

(74) Agent: BARANOWSKI, Edwin, M.; Porter, Wright, Mor- ris & Arthur, 41 South High Street, Columbus, OH 43215 (US).

(81) Designated States: AT (European patent), AU, BE (Euro- pean patent), CA, CH (European patent), DE (European patent), DK (European patent), ES (European patent), FR (European patent), GB (European patent), GR (Eu- ropean patent), IT (European patent), JP, KR, LU (Euro- pean patent), NL (Buropean patent), SE (European pa- tent), US.

(57) Abstract

An injector system comprising an improved method and apparatus useful in the production of a hydrogen containing fuel gas from water in a process in which the dielectric property of water and/or a mixture of water and other components determines a resonant condition that produces a breakdown of the atomic bonding of atoms in the water molecule. The injector delivers a mixture of water mist (1), ionized gases (2), and non-combustible gas (3) to a zone or locus (5) within which the breakdown pro- cess leading to the release of elemental hydrogen from the water molecules occurs.

WATER FUEL INJECTION SYSTEM

This invention relates to a method and apparatus useful in producing thermal combustive energy from the hydrogen component of water.

In my patent no. 4,936,961, "Method for the Production of a Fuel Gas," I describe a water fuel cell which produces a gas energy source by a method that utilizes water as a dielectric component of a resonant electrical circuit.

In my patent no. 4,826,581, "Controlled Process for the Production of Thermal Energy From Gases and Apparatus Useful Therefore,” I describe a method and apparatus for obtaining the enhanced release of thermal energy from a gas mixture including hydrogen and oxygen in which the gas is subjected to various electrical, ionizing and electromagnetic fields.

In my co-pending application serial no. 07/460,859, “Process and Apparatus for the Production of Fuel Gas and the Enhanced Release of Thermal Energy from Fuel Gas," I describe various means and methods for obtaining the release of thermal/combustive energy from the hydrogen (H) component of a fuel gas obtained from the disassociation of a water (HzO) molecule by a process which utilizes the dielectric properties of water in a resonant circuit; and in that application I more thoroughly describe the physical dynamics and chemical aspects of the water-to-fuel conversion process.

The invention of this present application represents a generational improvement in methods and apparatus useful in the utilization of water as a fuel source. In brief, the present invention is a micro-miniaturized water fuel cell and permits the direct injection of water, and its simultaneous transformation into a hydrogen containing fuel, in a combustion zone, such as a cylinder in an internal combustion engine, a jet engine, or furnace. Alternatively the injection system of the present invention may be utilized in any non-engine application in which a concentrated flame or heat source is desired, for example, welding.

The present injection system eliminates the need for an enclosed gas pressure vessel in a hydrogen fuel system and thereby reduces a potential physical hazard heretofore associated with the use of hydrogen-based fuels. The system produces fuel on demand in real-time operation and sets up an integrated environment of optimum parameters so that a water-to-fuel conversion process works at high efficiency.

The preferred embodiment of the invention is more fully explained below with reference to the drawings in which:

Figure 1 figuratively illustrates the sections and operating zones included in a single injector of the invention.

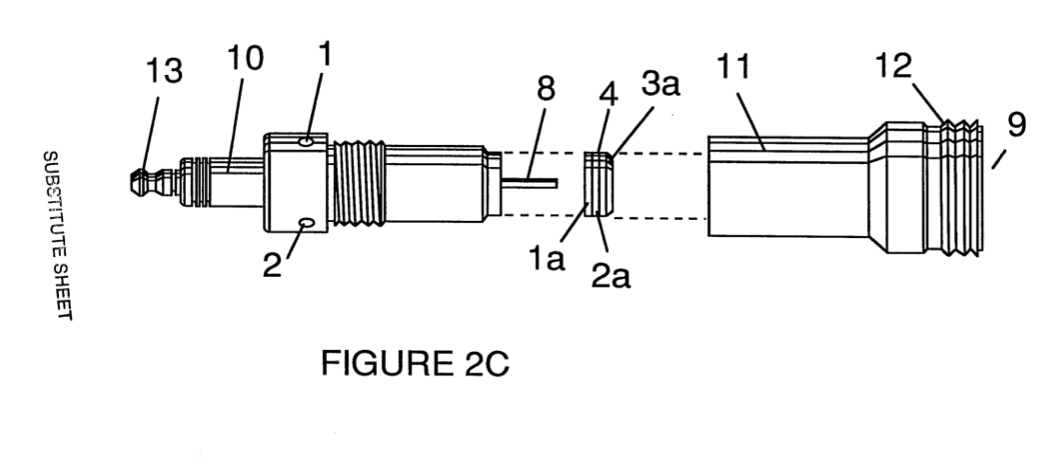

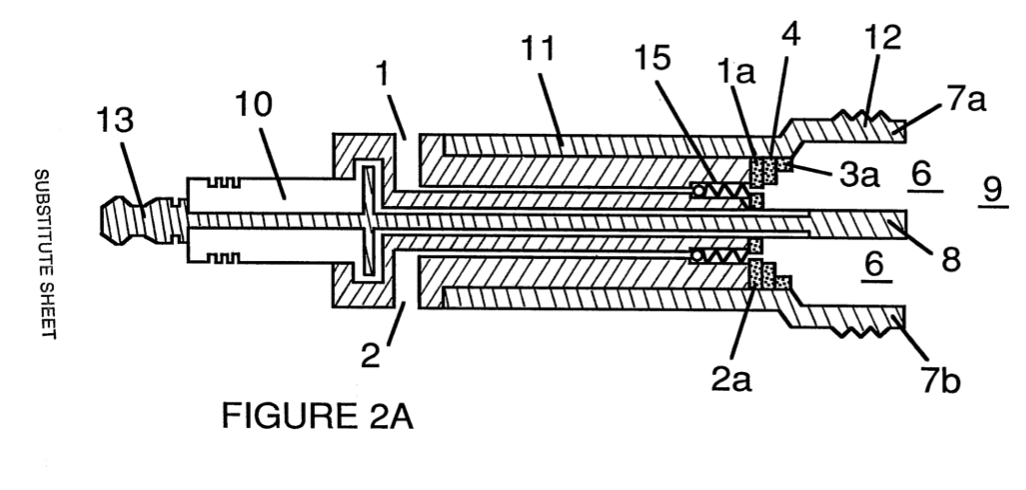

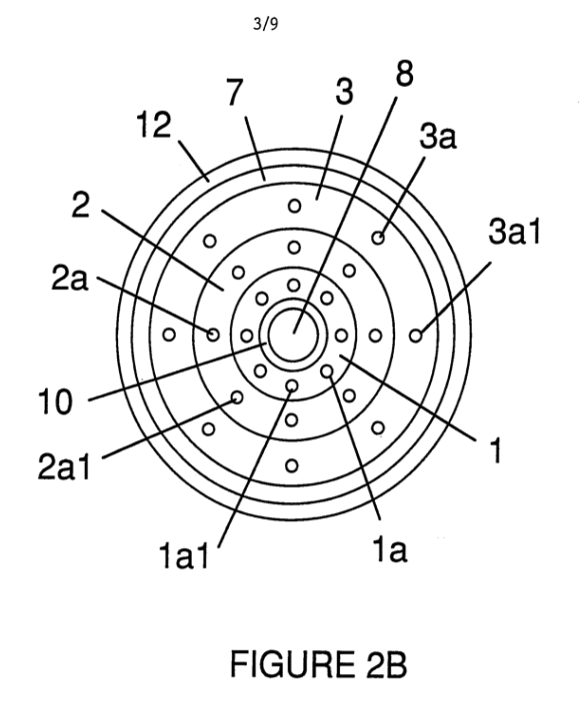

Figure 2A is a side cross sectional view; Figure 2B is a frontal view from the operative end; and Figure 2c is an exploded view -- of an individual injector.

|

|

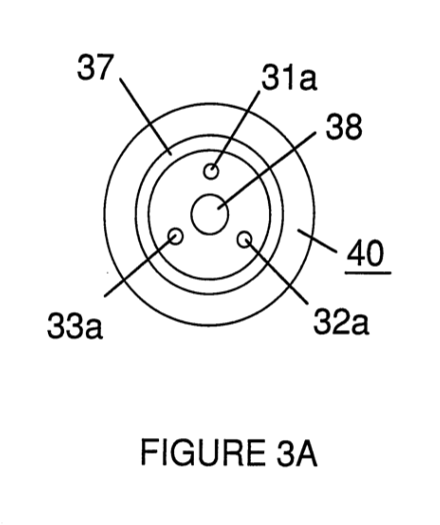

Figure 3A and Figure 3B respectively show a side cross-section view and frontal view of an alternatively configured injector.

|