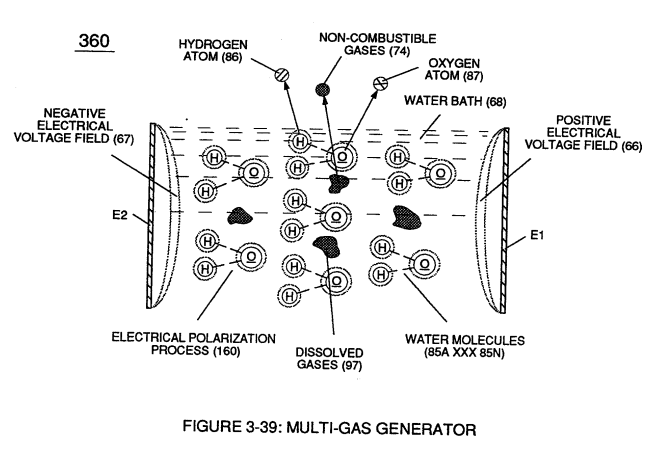

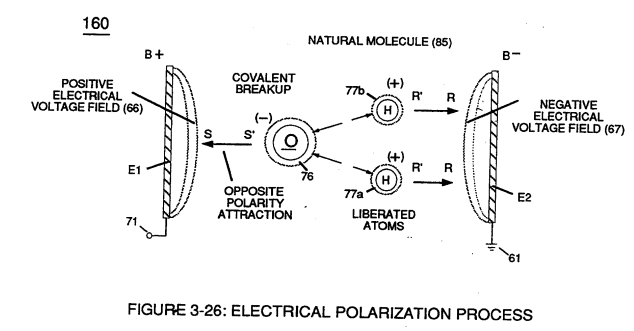

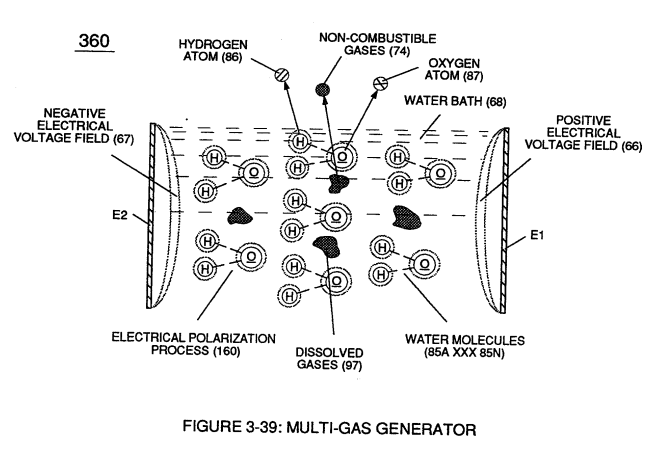

| **Dissolved air gases** (97) of Figure (3-39) [](https://stanslegacy.com/uploads/images/gallery/2023-12/DapPTPnafhxr0u3b-image-1703378524117.png) | **Electrical Polarization Process** (160) of Figure (3-26) [](https://stanslegacy.com/uploads/images/gallery/2023-12/FI7iyHF5qFsbEw5X-image-1703376323691.png) |

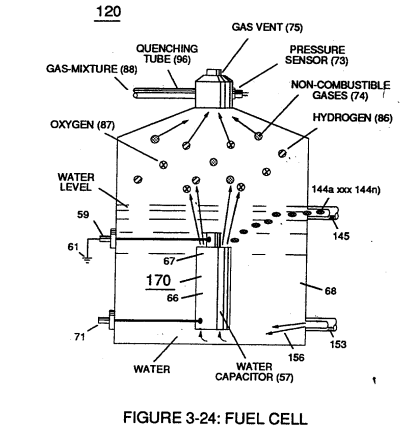

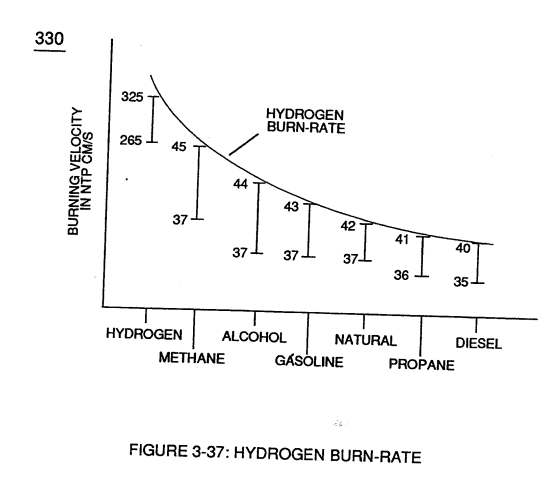

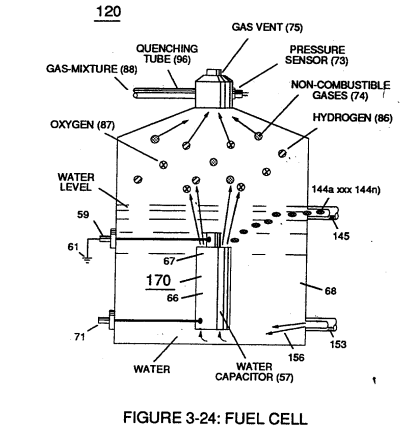

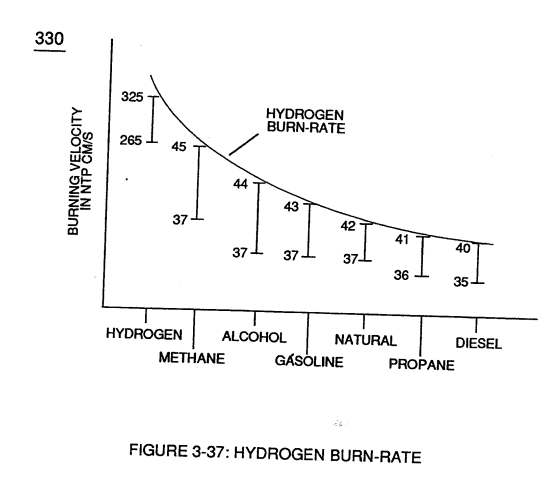

| **Fuel-Gas mixture** (88) of Figure (3-24) [](https://stanslegacy.com/uploads/images/gallery/2023-12/eS2UmsVf6o8YkE39-image-1703377231066.png) | (330) of Figure (3-37) [](https://stanslegacy.com/uploads/images/gallery/2023-12/WlQY61kCMBoWAmvg-image-1703378872882.png) |

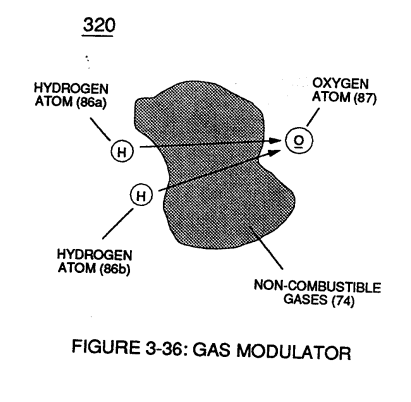

| (320) of Figure (3-36) [](https://stanslegacy.com/uploads/images/gallery/2023-12/rtVP70fKKJltrRpY-image-1703269420703.png) | Figure (3-39) [](https://stanslegacy.com/uploads/images/gallery/2023-12/DapPTPnafhxr0u3b-image-1703378524117.png) |

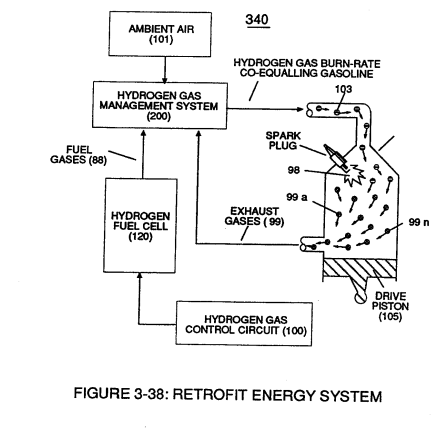

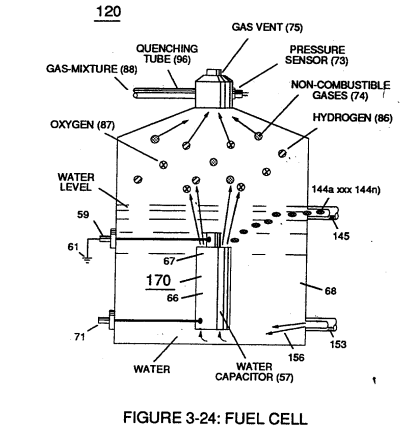

| (340) of Figure (3-38) [](https://stanslegacy.com/uploads/images/gallery/2023-12/MeLbNiqN8Ishsstr-image-1703379003610.png) | Figure (3-24) [](https://stanslegacy.com/uploads/images/gallery/2023-12/eS2UmsVf6o8YkE39-image-1703377231066.png) |

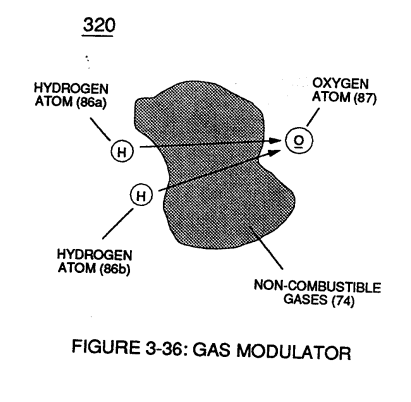

**Water bath** (68) of Figure (3-39) as to Figure (3-24), now, becomes and functions as a "**Gas Mixing Regulator**" since the highest possible **thermal explosive energy yield** (gtnt) obtainable from hydrogen during "normal" **gas ignition** (98) is the exact composition of water where **two hydrogen atoms** (86a / 86b) unite with **oxygen atom** (87).

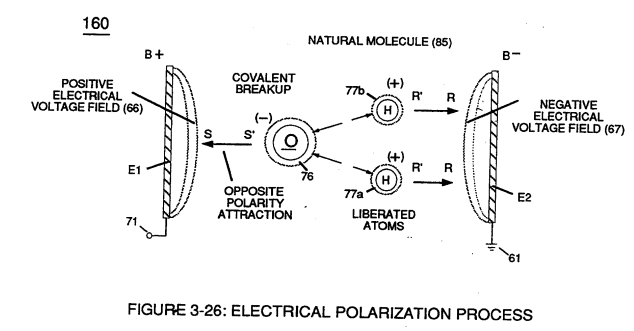

[](https://stanslegacy.com/uploads/images/gallery/2023-12/FI7iyHF5qFsbEw5X-image-1703376323691.png)Inherently, the utilization of the **Electrical Polarization Process** (160) of Figure (3-26) in conjunction with the use of chemically inert stainless steel (T304 material) **voltage zones** (E1 / E2) submerged in **natural water** (68) sustains and maintains **gas mixing ratio** (88) by simply preventing the consumption of both the **hydrogen** (86) and **oxygen** (87) gases by way of not encouraging "electrical heat" or "chemical interaction" associated with amp consumption.Remember, **Electrical Polarization Process** (160) is a physical process which uses **opposite electrical polarity attraction force** (qq') to perform work by disrupting and switching off the covalent bond between the unlike charged water molecule atoms.

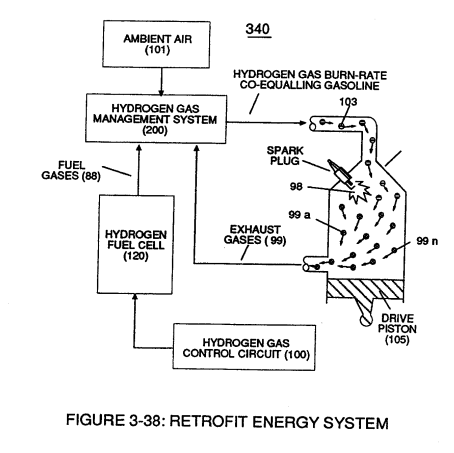

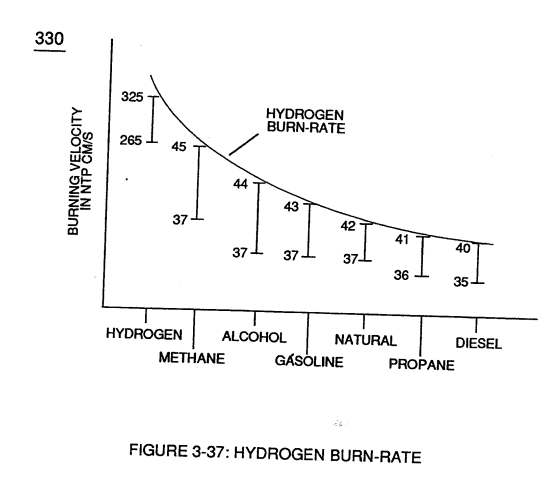

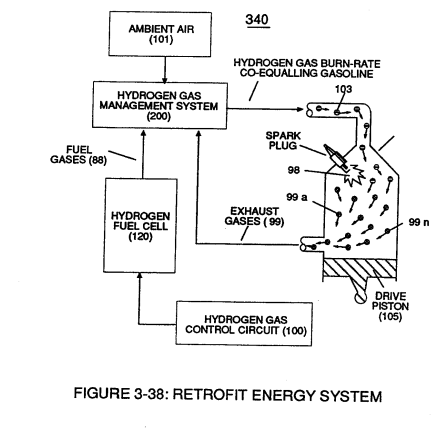

To further reduce **hydrogen burn-rate** (330) of Figure (3-37) to other fossil-fuel burning levels, additional **non-combustible gases** (99a xxx 99n) (*supplied via ambient air 101*) is added to **gas-mixture** (88) by way of **gas ignition process** (98) occurring inside **internal combustion engine** (55) **piston cylinder** (102), as illustrated in (340) of Figure (3-38).

| **hydrogen burn-rate** (330) of Figure (3-37) [](https://stanslegacy.com/uploads/images/gallery/2023-12/WlQY61kCMBoWAmvg-image-1703378872882.png) | (340) of Figure (3-38) [](https://stanslegacy.com/uploads/images/gallery/2023-12/hCQI9T9DxApWIQWc-image-1703231476158.png) |

... releasing **thermal explosive energy** (gtnt) which, in turns, causes piston-action to expel the newly formed **non-combustible exhaust gases** (99) for recycling.

The liberated and cooled **exhaust gases** (99) is, now, directed to **hydrogen injector system** (200) which systematically meter-mixes and superimposes a predetermined amount of **non-burnable gases** (99) of Figure (3-38) onto incoming **ambient air gases** (101) which is being directed to **engine cylinder** (102) to sustain and maintain both the "**Gas Modulator Process**" (320) of Figure (3-36) and the "**Gas Ignition Process**" (98), simultaneously.

| "**Gas Modulator Process**" (320) of Figure (3-36) [](https://stanslegacy.com/uploads/images/gallery/2023-12/rtVP70fKKJltrRpY-image-1703269420703.png) | (340) of Figure (3-38) [](https://stanslegacy.com/uploads/images/gallery/2023-12/hCQI9T9DxApWIQWc-image-1703231476158.png) |

In essence, then, **ambient air gases** (101) becomes an endless supply of **non-combustible gases** (99A xxx 99n) during the gas ignition process.

The resultant and on-going **Gas Modulator Process** (320) of Figure (3-36), now, allows **hydrogen fuel cell** (120) of Figure (3-24) to be retrofitted to any conventional **internal combustion engine** (55) of Figure (3-1) without engine change by simply metering the proper amount of **exhaust gases** (99a xxx 99n) to comply with and co-equaling any type or different fossil-fuel burning levels, as further illustrated in (330) of Figure (3-37).| **Fuel-Gas mixture** (88) of Figure (3-24) [](https://stanslegacy.com/uploads/images/gallery/2023-12/eS2UmsVf6o8YkE39-image-1703377231066.png) | (330) of Figure (3-37) [](https://stanslegacy.com/uploads/images/gallery/2023-12/WlQY61kCMBoWAmvg-image-1703378872882.png) |

In terms of operability and performance, **gas modulator** **process** (320) continues to allow a conventional **internal combustion engine** (55) to run on ambient air gases; while, **fuel-gas** (88) not only cuts back and reduces oxygen extraction form ambient air (101) but produces a environmentally safe exhaust gases since **non-combustible gases** (99/74) from both **ambient air gases** (101) and **Fuel-Gas** (88) are thermally inert to **gas ignition process** (98).