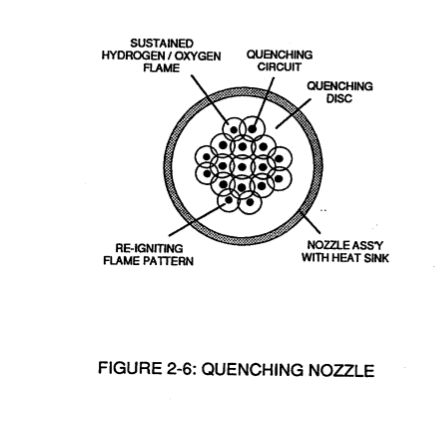

Additional Quenching Circuits arranged in a Disc-shape configuration forms a "Quenching Nozzle" when attached to an "Quenching Tube", as illustrated in Figure (2-4) as to Figure (2-6).

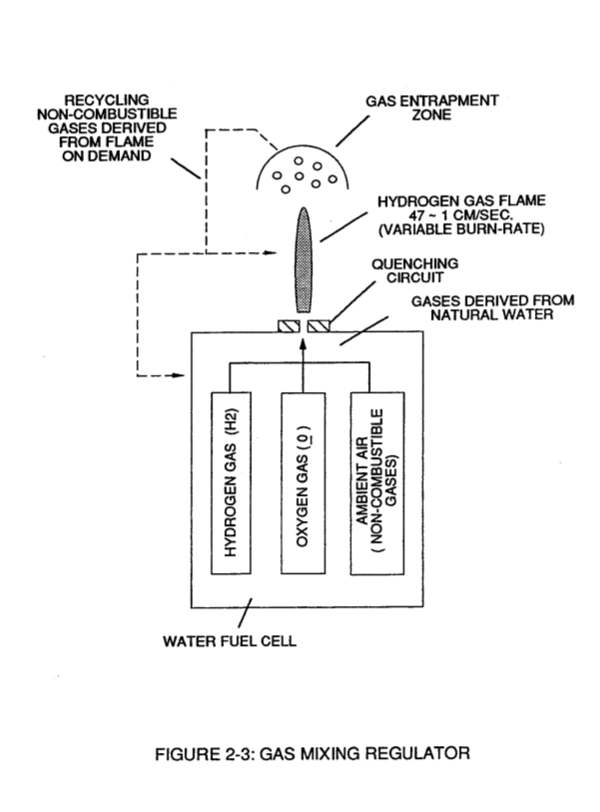

| Figure (2-3) [](https://stanslegacy.com/uploads/images/gallery/2023-12/vHikAM9oiGf9RNxB-image-1702961652974-54-10.png) | Figure (2-6) [](https://stanslegacy.com/uploads/images/gallery/2023-12/7UGJBw4kZB7ddVvy-image-1702961676853-54-34.png) |