US Patents

WFC Patents files in the United States

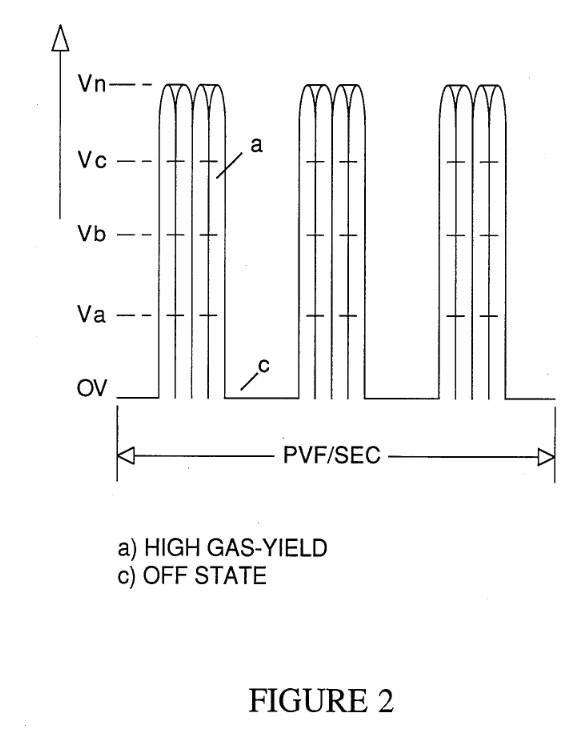

- Full Patent List

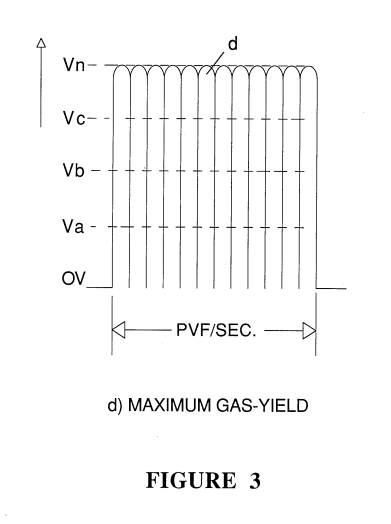

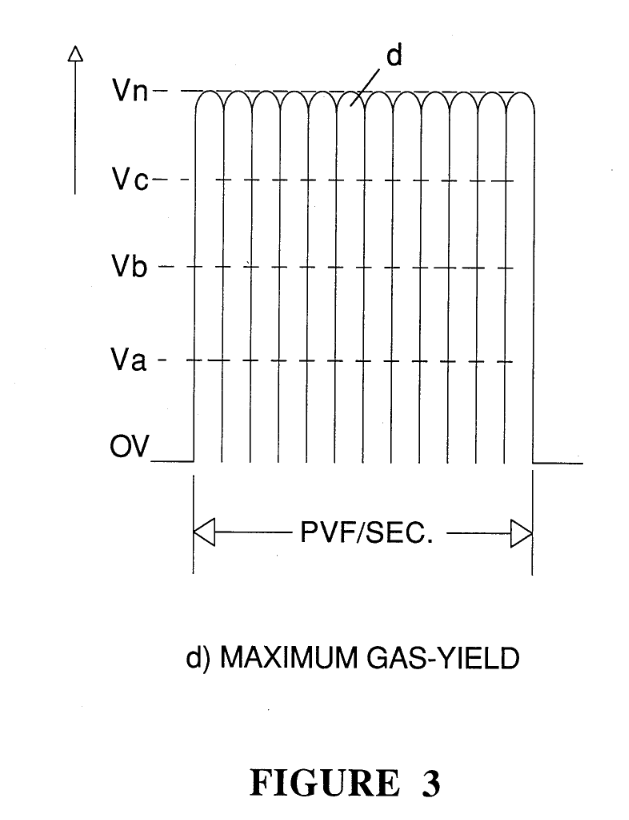

- Solar Heating System #3,970,070

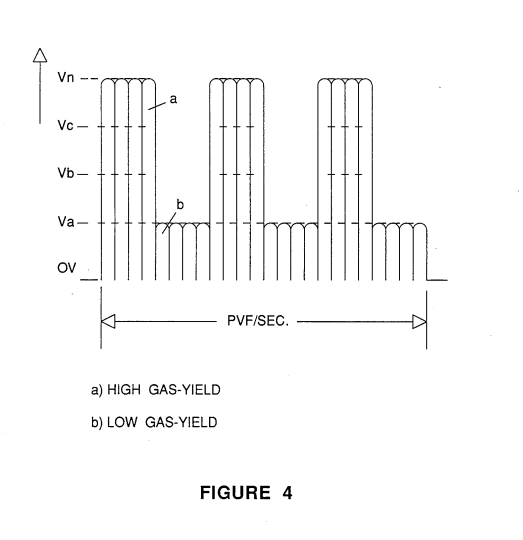

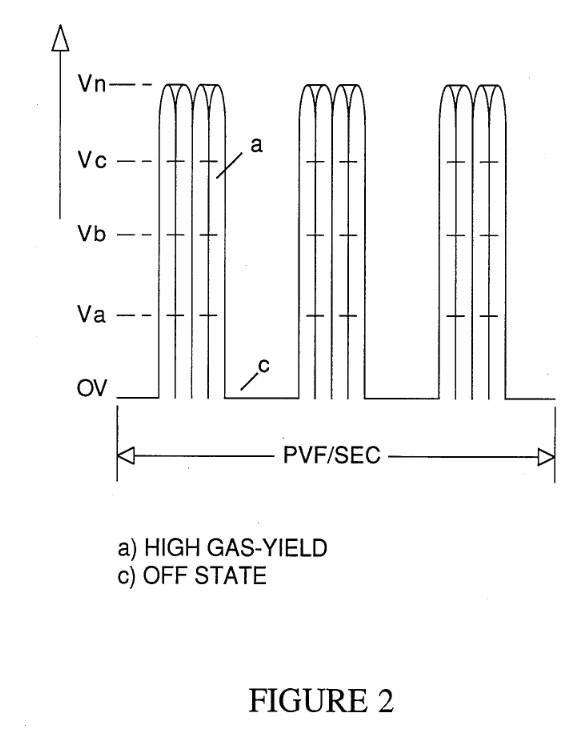

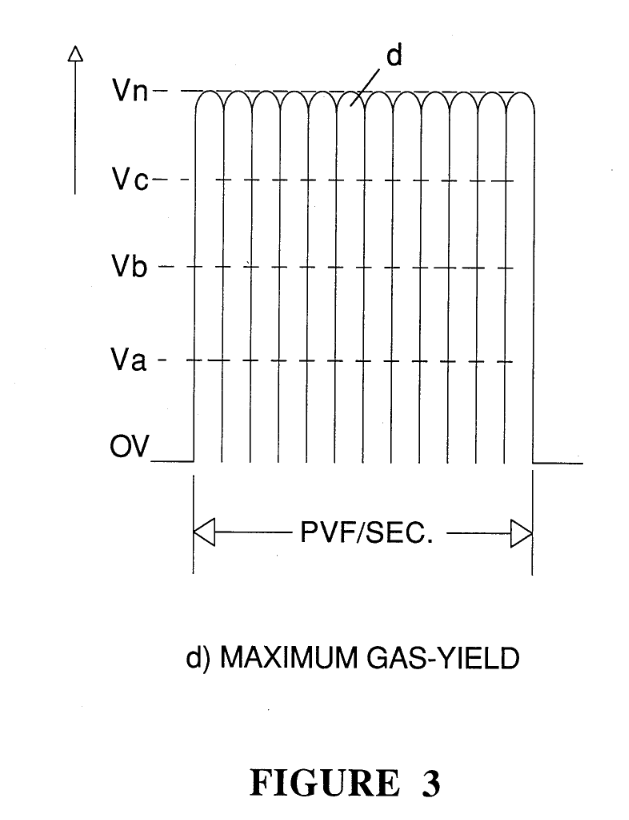

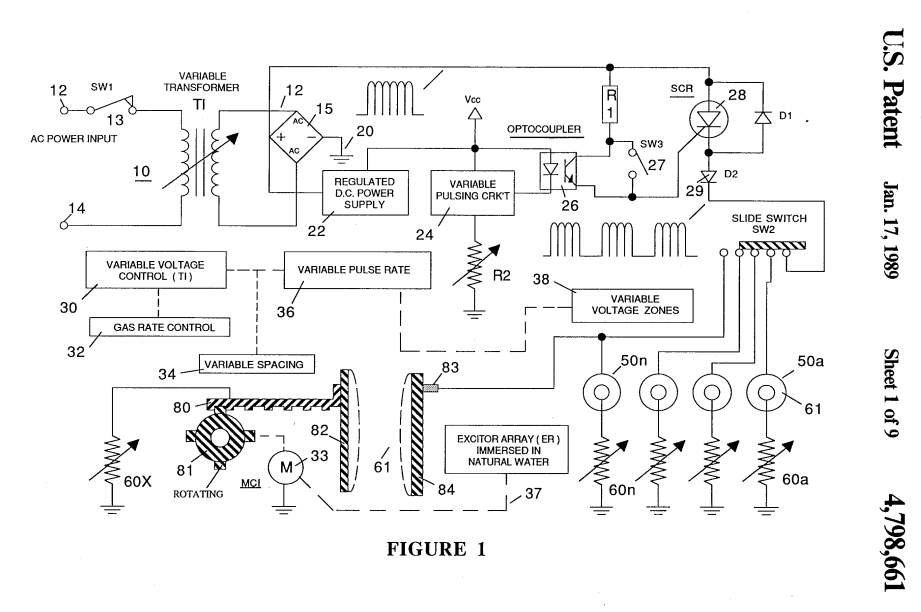

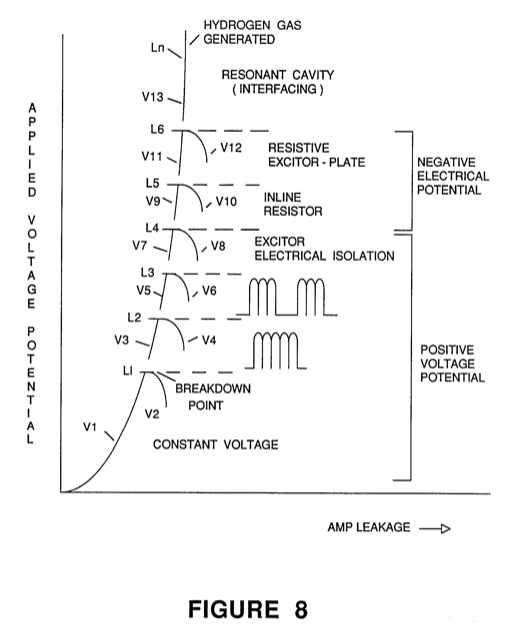

- MultiStage Solar Storage System #4,265,224

- Light Guide Lens #4,275,950

- Light Guide Lens #4,275,950 - Illustrations

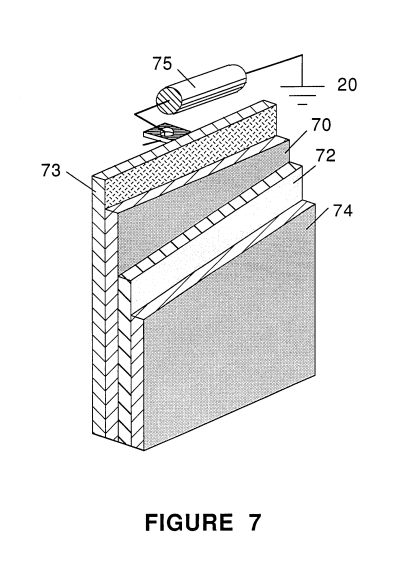

- Hydrogen Gas Injector System For Internal Combustion Engine #4,389,981

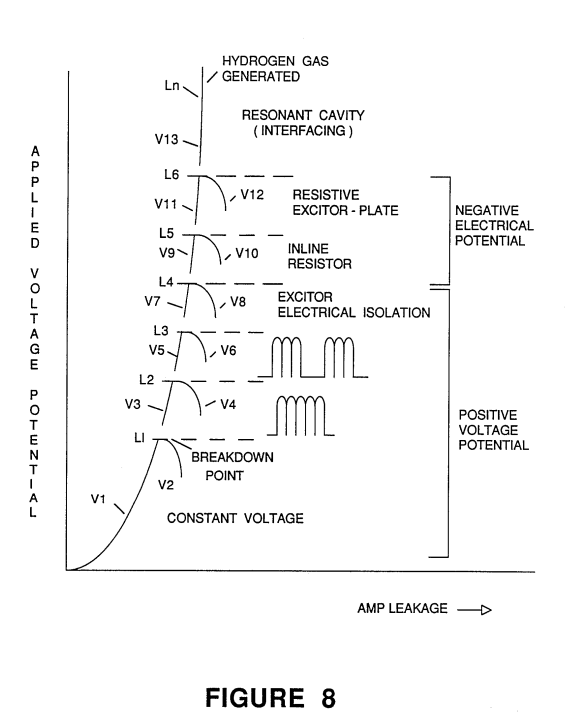

- Hydrogen Gas Burner #4,421,474

- StartUp ShutDown For A Hydrogen Gas Burner #4,465,455

- Gas Electrical Hydrogen Generator #4,613,304

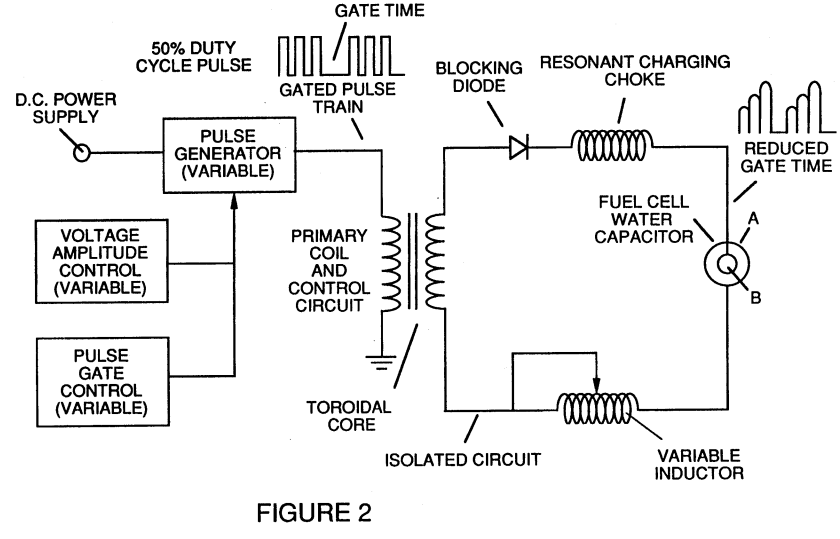

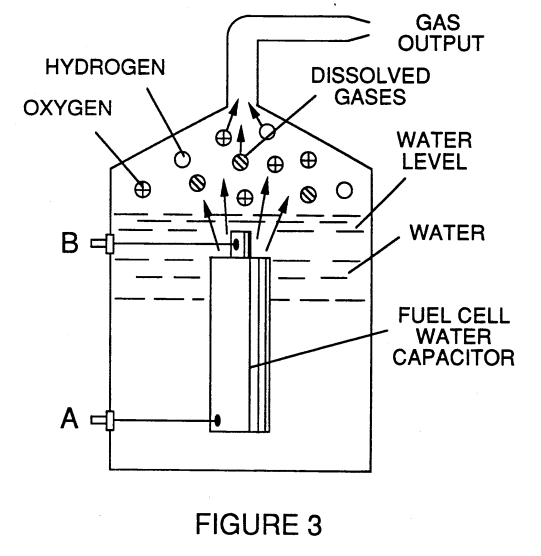

- Electrical Pulse Generator #4,613,779

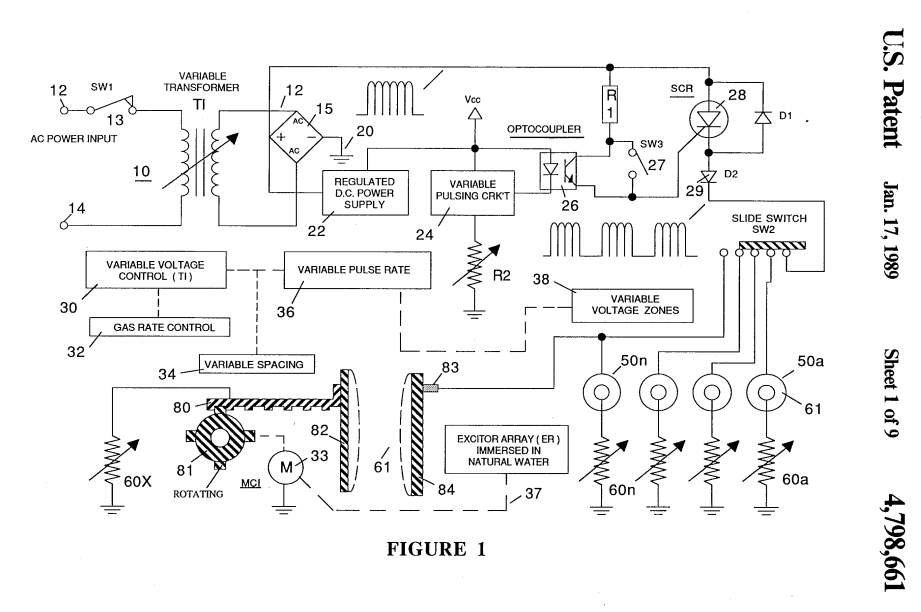

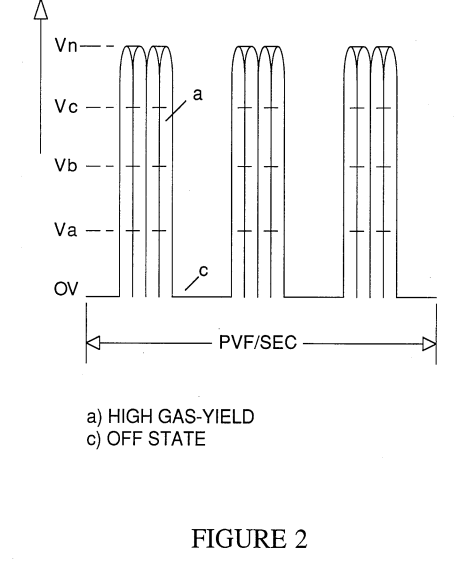

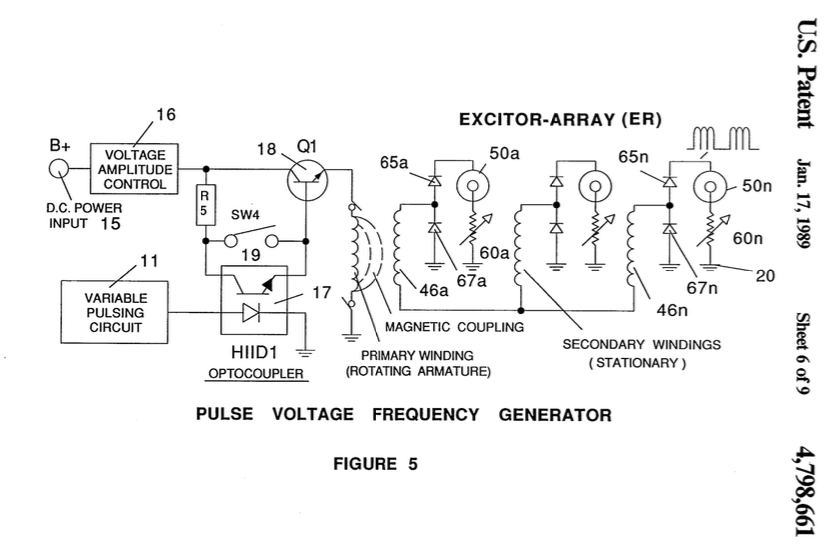

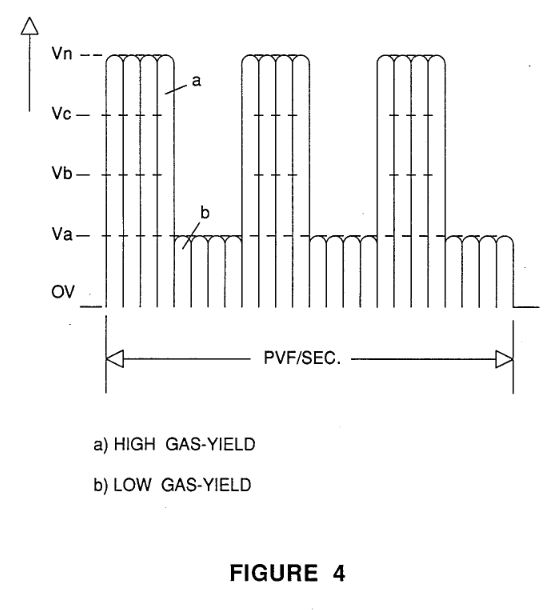

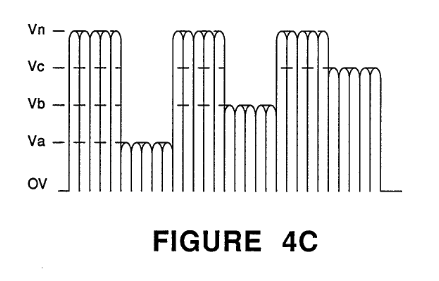

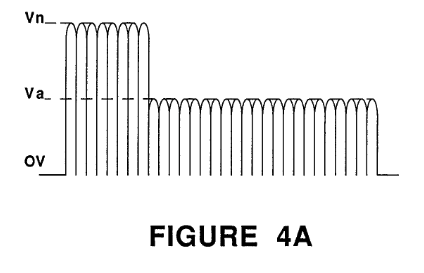

- Gas Generator Voltage Control Circuit #4,798,661

- Controlled Process For The Production Of Thermal Energy From Gases And Apparatus Useful Therefore #4,826,581

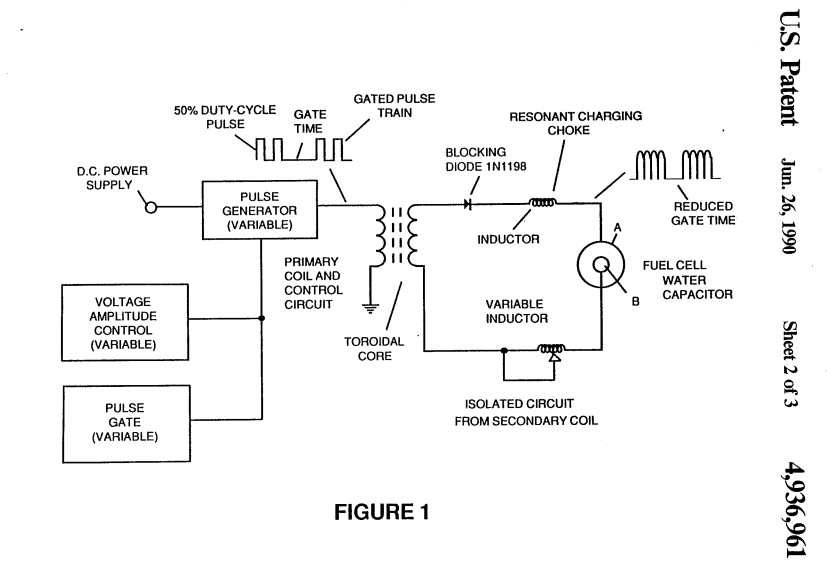

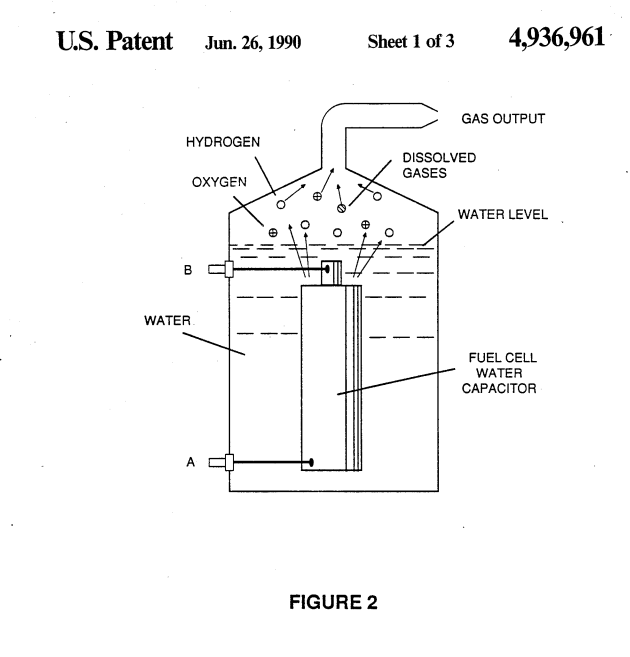

- Method For The Production Of A Fuel Gas #4,936,961

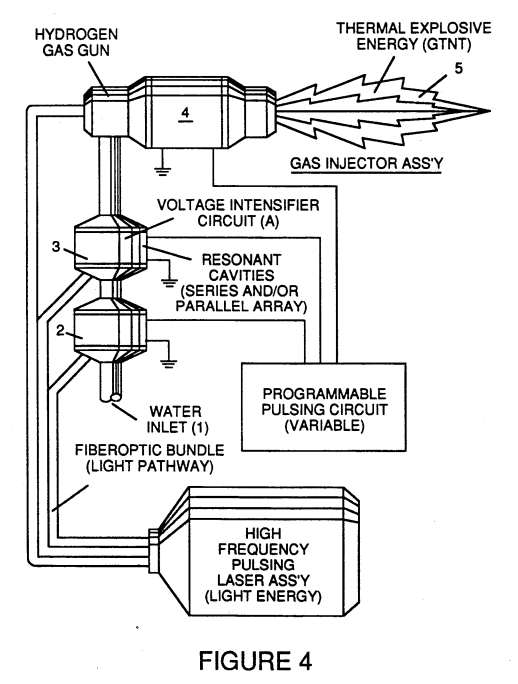

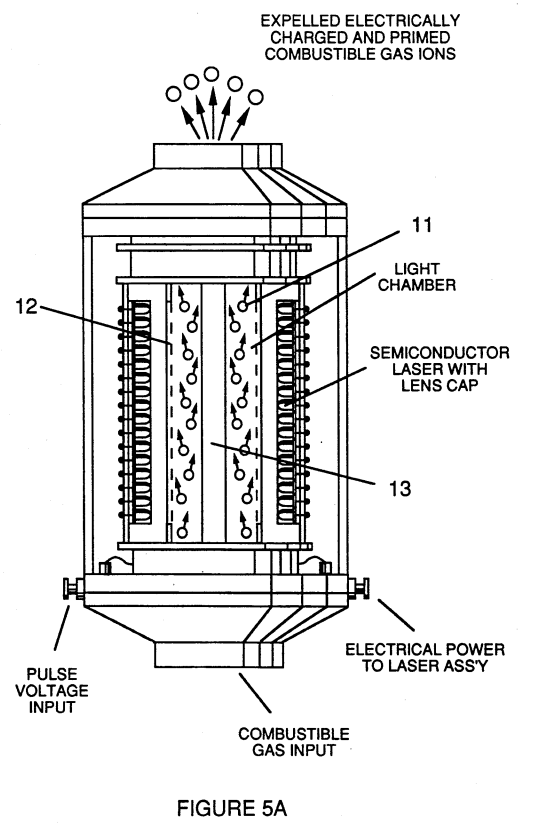

- Process & Apparatus For The Production Of Fuel Gas & The Enhanced Release Of Thermal Energy From Such Gas #5,149,407

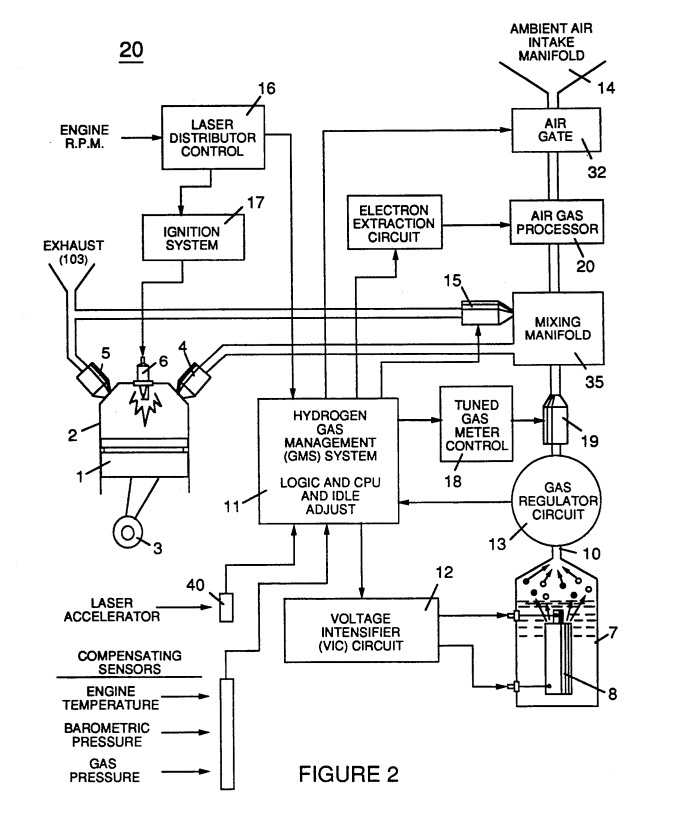

- A Hydrogen Gas Fuel And Management System For An Internal Combustion Engine Utilizing Hydrogen Gas Fuel #5,293,857

Full Patent List

SMeyer-US3970070-Solar_Heating_System

SMeyer-US4265224-MultiStage_Solar_Storage_System

SMeyer-US4275950-Light_Guide_Lens

SMeyer-US4389981-Hydrogen_Gas_Injector_System_For_Internal_Combustion_Engine

SMeyer-US4421474-Hydrogen_Gas_Burner

SMeyer-US4465455-StartUp_ShutDown_For_A_Hydrogen_Gas_Burner

SMeyer-US4613304-Gas_Electrical_Hydrogen_Generator

SMeyer-US4613779-Electrical_Pulse_Generator

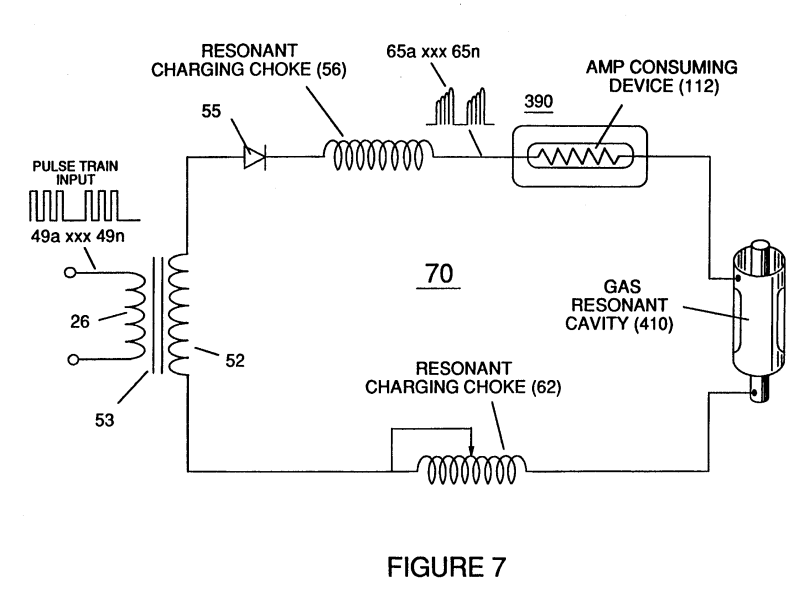

SMeyer-US4798661-Gas_Generator_Voltage_Control_Circuit

SMeyer-US4936961-Method_For_The_Production_Of_A_Fuel_Gas

Solar Heating System #3,970,070

United States Patent

Meyer et al.

Patent No: 3,970,070

Date: July 20, 1976[54] SOLAR HEATING SYSTEM

[76] Inventors: Stanley A. Meyer, 2931 Bryden Road; Stephen R. Gray, 2722 Allegheny Ave., both of Columbus, Ohio 43209[22] Filed: Sept. 3, 1975

[21] App. No.: 610,051

[52] U.S. Cl. ................................. 126/271; 350/96 B

[51] Int. Cl. ..................................... F24J 3/02

[58] Field of Search .................... 237/1 A; 126/270, 271; 350/96 B[56] References Cited

UNITED STATES PATENTS

1,951,403 Goddard .......... 126/271

1,969,839 Goddard .......... 126/271

2,213,894 Barry ............... 126/271

3,046,414 Sandness ........ 126/270

3,252,456 Bohn Jr. .......... 126/271

3,780,722 Swet .............. 126/270Primary Examiner — Kenneth W. Sprague

Attorney, Agent, or Firm — Cennamo Kremblas & Foster

[57] ABSTRACT

A solar heating system comprising a lens collector arrangement, an insulation area, and a storage section positioned in an enclosing structure, and an associated utilization means. The collector lens is an array of light guide lenses having internal high and low refractive surfaces. The array is contoured in a capping relationship over a focusing lens to provide an extremely high concentration of solar energy irrespective of the angle of the sun. The light guide lenses increase by several orders of magnitude the amount of solar energy striking the surface of the focusing lens. The focusing lens is a plurality of flat surface type of lenses stacked one over the other in spaced relationship and operable to concentrate the solar energy to a central region. Surrounding the perimeter of the plurality of focusing lenses in an array, in a "wall" configuration, of light guide lenses similar in construction to the aforesaid capping light guide lenses. The angle of the reflective surfaces of the capping lenses and the wall lenses is such as to receive and direct to the focusing lenses the maximum amount of radiation at all times of the day and season. The insulation area is positioned between the collector lens and the storage section to provide a convective barrier for the storage area without inhibiting the passage of solar radiation. The storage section is of a high absorptive material with an auxiliary conventional heat source.

SOLAR HEATING SYSTEM

CROSS REFERENCE

The "Light Guide Lens" of the co-pending application filed Sept. 3, 1975, by the same inventors herein and given Ser. No. 609,928, is that utilized in the present invention.

BACKGROUND

With the energy crisis created by the impact of the natural resources shortage, together with the anticipated depletion of the natural resources, a considerable amount of effort has been directed to other forms of energy. Although there are several other forms of energy, the emphasis has been placed on solar energy as the most logical heat source. Consequently, there are on the market many so-called solar furnaces.

These prior art devices generally comprise a focusing lens, a medium - either air or liquid - to be heated, in some instances a storage tank, and in other instances a reflective surface such as a mirror and/or a reflector.

Although these solar furnaces are operable and in certain instances commercially operable, they are not without their attendant disadvantages. Principally the problem area is a lack of a sufficient concentration system for the incident solar energy, directivity relative to the angle of the sun, and a storage system with a capacity to carry the system on cloudy days. The problem related to the concentration of the solar energy is with the lens and its reflecting surfaces and the response of the system to the low angles of the sun.

Further, the prior art systems generally utilize the solar radiation to heat either a liquid or air directly and then utilize the heated air or water for the intended purpose. Storage systems are much fewer and are of the indirect type, that is, the heated excess air or liquid is placed in a storage medium. These prior art storage systems are very simple in structure and somewhat crude. Very little advance in the art has been made with storage systems.

Although perhaps in some future period of time solar energy may be a complete substitute for other forms of energy, today solar energy, at best, is a supplement to or an alternate source of energy. Nonetheless, the failures of the prior art to recognize the practical usefulness of solar energy systems resulted in commercial systems that are extremely expensive but, yet, of only a minimal and questionable value.

SUMMARY OF INVENTION

The invention comprises in its most general aspects a unitary air/liquid tight cylindrical enclosure that houses a combination of components that are responsive sequentially to solar radiation. The system provides a heat source with a larger capacity and operable for an extended period of time over that of the prior art. Within the cylindrical enclosure, the components comprise in the order of operability a collector lens, an insulating area, and a storage section. Utilization means for effectively utilizing the heat generated is associated with the basic combination of apparatus.

The collector lens, the insulation area, and the storage section are serially joined together and housed in an air/liquid tight cylindrical (with appropriate vents) enclosure that is insulated against heat loss.

BRIEF DESCRIPTION OF DRAWINGS

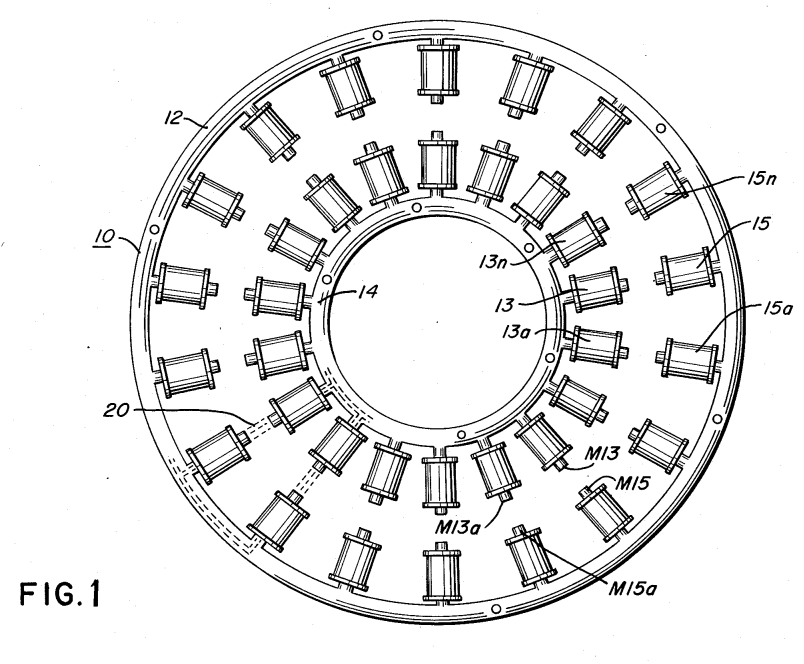

FIG. 1 is an overall schematic plan view illustrating the preferred embodiment of the present invention.

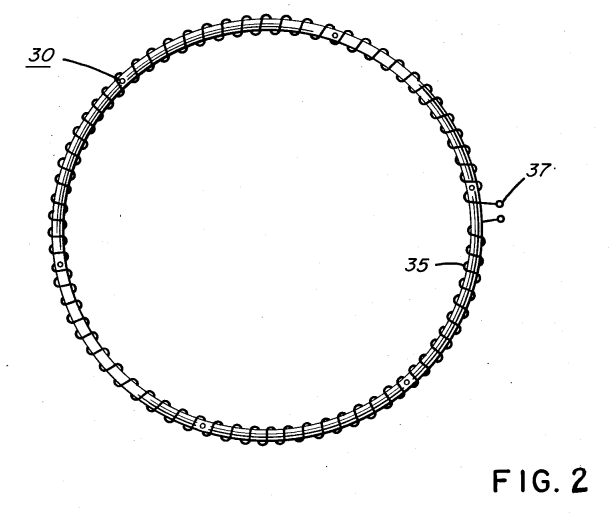

FIG. 2 illustrates a preferred lens arrangement shown generally as indicated herein for use of FIG. 1.

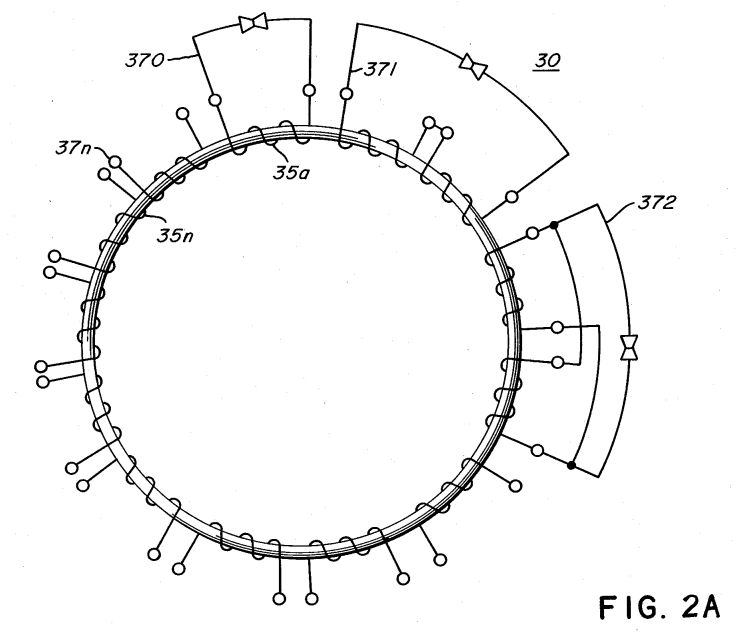

FIGS. 2A through 2F are various alternate embodiments of the light guide lens utilized in the present invention.

DETAILED DESCRIPTION OF DRAWINGS

With particular reference now to FIG. 1, there is illustrated schematically a preferred embodiment of the present invention. It is most fundamental form of a solar heater comprises a housing enclosure 10, light energy concentrator 20, an insulation area 30, a heat storage section 40, and a utilization means 50.

In principle of operation, the concentration lens arrangement 20 is capable of directing a maximum amount of solar radiation to its focusing lens. The solar radiation is directed to focusing lens from all angles irrespective of the position of the sun overhead or on the horizon.

The focused solar radiation passes through an insulation barrier 30 to a thermal storage section 40. The insulation barrier 30 has a dual effect: to either inhibit the passing of thermal radiation (convective barrier). Once solar radiation is converted to thermal radiation the "heat" is stored in the thermal storage section 40, depleted by the energy demands from 50.

In actual operation the storage section 40 is the heat source. With a given capacity and the extremely efficient solar energy storage and retention, an extremely large amount of thermal energy heretofore not possible with other solar systems is obtained.

The solar heating system described above has an extremely broad and practical utilization range. However, it is not intended as "primary" energy supply but rather as a supplement to the conventional power sources.

The invention allows for continued heat storage and transfer from this stored energy and release at pre-determined times, for instance, on cloudy days or after sunset.

In the event that the storage section should exceed a certain predetermined thermal gradient (such as can occur during extended periods of "sunny" days) a heat sink arrangement is provided for the storage section to dissipate the excess energy. Additionally, a shelter arrangement and temperature-controlled unit in a conventional manner is provided for the heat storage.

The solar energy lens 20 of FIG. 1 is shown more explicitly (again schematically) in FIGS. 2A, 2B, 2C, 2D, 2E, and 2F as alternate lens constructions which may be used. The basic method for utilizing the lenses of the preferred embodiment is to position them similar to prior art, such as in U.S. Ser. No. 609,928 filed Sept. 3, 1975.

Basically, each light guide lens in this array comprises alternate high refractive (transparent) material such as glass or high refractive plastics.

The early lens 28 will receive the transmitted radiation from lens 26. Surrounding the lenses 24, 26, and 28 and the spacing therebetween is the light guide lens array 29. This lens 29, too, like the capping lens 22, is made up of high and low refractive (transparent and reflective) materials. Accordingly, in passing from lens 24 to 28, the solar radiation is confined to a shorter transition striking the reflective surfaces 29a such that the light guide lenses 22.1 direct the solar radiation to the surface of the focusing lens 24 and 28.

As indicated above, the angle of the solar radiation transmitted (passing to focusing lens 24) is dependent on the angle of the incident solar radiation, the wavelength of the solar radiation and the wavelength length of the guide (reflective surface). The light guide lens comprising the capping lens 22 are generally in the vertical or displaced from the vertical relative to the lens shown.

However, the light guides comprising the wall lens 28 are generally in both the horizontal and displaced from the horizontal relative to the angles of the sun. The primary direction of the wall light guides 22.1 in the vertical is displaced 90 degrees from the horizontal.

The light guides 26 and 28 are each arranged as flat surfaces with a high rate of absorption to solar radiation.

The primary function is to collect the solar radiation from the outermost edge and pass it inwardly, reflecting the solar radiation towards the central structure of the solar heating system.

The additional focusing lenses 26 and 28 in the preferred embodiment shown in FIG. 1 are similarly constructed to the capping lenses.

Referring again to the focusing of FIG. 1, the solar radiation focused by the focusing lens 24 is directed through the insulation area 30. The insulation area 30 is a sealed engagement with the insulator 33 comprising a pool of glass with insulating material such as salts 32. The purpose and function of the insulation area 30 is to prevent the heat energy from escaping during cloudy days or after sunset.

Particularly, the insulation area in the preferred embodiment is a liquid solution, such as a salt compound, and the heat converts the liquid solution into horizontal stratifications.

With the salt layer of the preferred embodiment, heat energy storage is maintained by the refractive material. The heat is allowed to accumulate over long periods of time during sunny days and released during cloudy days.

As indicated above, the solar radiation passes through a storage cavity filled with a liquid material or solution, such as salt. This material has a high rate of absorption to solar radiation. The stored heat is transferred for energy purposes during "off-peak" periods.

... given material having a high rate of absorption to the particular solar radiation that is desired. The lenses and salt pool provide the means for storing solar radiation.

Positioned in the lower region of the thermal storage section 40 is the heat collector and extraction assembly 47. The solar heating array 67 is conventional and may take other known forms. Connected to both sides of the collector plates 47 is the conductive thermal transfer means which is connected to heat exchanger means 50. Heat expulsion is induced by a heat utilization means 50 also conventional and commercially operable.

The solar heater of the present invention is intended as the primary heat source and may be utilized for the home or commercially. The size of the unit, although its relative size to other solar units is most small, would be increased depending on the market area to be heated. However, with the extremely efficient collector lens 28 in reality, it is only the storage area that need to be increased. Alternatively, individual units can be modularly stored, distributed throughout a given area.

It is appreciated, of course, that there may be periods of time when the sun doesn't "shine" and this may be especially disadvantageous in the winter months when the days are the shortest. Realistically, the time solar heater system of the present invention, although having a much greater and effective storage system, cannot be operated indefinitely during these "dark" periods of time when the temperature of the storage system drops below a predetermined standard. An auxiliary heat source can be connected to automatically operate, or the solar heater system itself can be cut off from energy.

The overall construction of the solar heater of the present invention is rugged, durable, and economical. The preferred embodiment was chosen to be cylindrical with a semi-flat top lens. The advantage of this configuration is that the system does not have to follow the sun. The lens is equally operative with the sun at any given angle.

It is recognized, however, that in certain climates, where it is desirable to move the solar energy for other purposes or the lenses require more exposure, more exotic glass or plastic dome lens applications may be constructed. The cover 61 of FIG. 6 can be replaced, if desired, with the lens 62 in the preferred embodiment, which can comprise metal coverings with a corrugated outer portion that supports the solar radiation system, and the lens has a cover frame that supports the lens.

It should be understood that other forms of lenses, including glass or synthetic plastic materials, can be employed for the focusing lens 28, depending on the specific climatic region. The angle, refractive index, and focal length of the various lenses can be adjusted accordingly to the sun's intensity.

It is to be noted that the present invention is illustrative only and that other modifications may be had therein without departing from the true spirit and scope of the invention.

What is claimed is:

-

A solar heater, comprising in combination:

- A collector lens positioned in the topmost region of said enclosure, and said collector lens comprising an array of light guide lenses of alternating high and low refractive material and focusing lens.

- A sealed enclosure positioned in the lowermost region of said enclosure for confining a thermal storage area of high capacity and solar radiant energy to thereby convert said solar radiant energy to thermal energy, with insulating means positioned within said enclosure intermediate of said lens and storage area, said insulating area further comprising a container with a liquid solution therein that prevents solar radiation and an isothermal convection barrier.

- And an enclosure further comprising a liquid and air seal to said lens, insulating area, and storage section, with utilization means for utilizing said thermal energy in said storage section.

-

The solar heater of claim 1 wherein said collector lens further comprises a plurality of spaced focusing lenses in a stacked relationship.

-

The solar heater of claim 2 where said focusing lenses each comprise a series of light guide prisms optically displaced from each other in various angles.

-

The solar heater of claim 3 wherein said focused prisms and wall lenses, with respect to the collector lens array and wall lens, will receive solar radiation directed inwardly and accumulated in a central focusing area to uniformly distribute said solar energy from the sun.

-

The solar heater of claim 4 wherein the primary direction of each set of light guides for said upper and lower lens sections is in the vertical with respect to the horizontal surface.

-

The solar heater of claim 4 wherein said focusing lens is circular, and the prisms are spaced circumferentially in an equal distribution.

-

The solar heater of claim 5 where said stacked focusing lenses are spaced apart by alternate regions of high refractive light guides, and at least one wall lens 28 is utilized in stacked and focused relationship to the focusing lenses 24.

-

The solar heater of claim 1 wherein said storage section further includes an auxiliary heat source thermally activated when the storage temperature exceeds a predetermined level.

Illustrations

MultiStage Solar Storage System #4,265,224

Light Guide Lens #4,275,950

Background

With the energy crisis created by the impact of consumption of non-renewable natural resources, together with a new emphasis on establishing clean standards associated with the usage of such natural resources, a considerable amount of effort has been directed to other forms of energy. Although there are several older forms of energy, the emphasis has been placed on solar energy as the most logical pollution-free recyclable energy source. Consequently, there are on the market many so-called solar focusing lenses.

These prior art devices generally comprise a focusing lens that is limited to a scan angle of sixty degrees (60°), and consequently are not capable of varying the effective angle while directionally focusing or dispersing the incident light radiation. The bulk of lenses of the various types are designed for use with a single stationary light source whether it be a single beam or incident light radiation in planetary array. Accordingly, the problems encountered with a single light source constantly varying its angular position are not appreciably enhanced for those instances where the problem has been encountered. Efforts have been made to have the lens "follow" the source.

In other instances where the light source is dispersed, the incident light rays upon the lens may be insufficient to render practical applications thereof. This has caused the need for others to augment the apparatus becomes extremely large, bulky, and of course expensive.

Summary of the Invention

The invention comprises in its most general aspects a unitary or collector-concentrator lens enclosure that houses a combination of light-guide lenses made up of arrays of light-deflecting lenses that collects, redirects, transfers, and focuses or disperses incident light radiation to a central region irrespective of the angle of the sun during the day or season. The lens system provides a heat source with an extremely larger capacity of high energy than known solar energy and operable to overhang any span for an extended period of time over that of prior art lenses.

The solar collector-concentrator lens configuration includes a plurality of spaced focusing light-guide lenses positioned over a first flare-shaped focusing lens. Beneath the focusing lens is a heat source. Light-guide lenses in similar vertical alignment fill the spaces defined by the perimeter of the transparent outer focusing lens array, in a well-known manner to assist in the engaging and focusing of the incident light, and deflect same into the boundary structure. Each of the light-guides includes a plurality of lens formations that steer light rays from its incoming source. The light-guides having a focusing means made out of one end of different refractive index materials light guide stems. The lens includes deflectors between adjacent formations of adjacent lens means, and may be linearly or non-linearly formed.

The lens can be vertically secured or configured horizontally to a light supporting beam and attached to a thermal chamber. Multiple concentric light guide units may be included in the focal plane on the interior reflective surfaces of the guide member.

Light Guide Lens #4,275,950 - Illustrations

PDF Download: Meyer #4,275,950 Light Guide Lens.pdf

|

|

Hydrogen Gas Injector System For Internal Combustion Engine #4,389,981

PDF Download: Meyer #4,389,981 Hydrogen Gas Injector System For Internal Combustion Engine.pdf

ABSTRACT:

System and apparatus for the controlled intermixing of a volatile hydrogen gas with oxygen and other non-combustible gasses in a combustion system. In a preferred arrangement the source of volatile gas is a hydrogen source, and the non-combustible gasses are the exhaust gasses of the combustion system in a closed loop arrangement. Specific structure for the controlled mixing of the gasses, the fuel flow control, and safety are disclosed.

CROSS REFERENCES AND BACKGROUND:

There is disclosed in my co-pending U.S. patent application Ser. No. 802,807 filed Sept. 16, 1981 for a Hydrogen-Generator, a generating system converting water into hydrogen and oxygen gasses. In that system and method the hydrogen atoms are disassociated from a water molecule by the application of a non-regulated, non-filtered, low-power, direct current voltage electrical potential applied to two non-oxidizing similar metal plates having water passing there-between. The sub-atomic action is enhanced by pulsing the non-regulated and non-filtered direct current voltage. The apparatus comprises structural configurations in alternative embodiments for segregating the generated hydrogen gas from the oxygen gas.

In my co-pending patent application filed May 1981, U.S. Ser. No. 262,744 now abandoned for Hydrogen-Aeration Processor, non-volatile and non-combustible gasses are controlled in a mixing stage with a volatile gas. The hydrogen aeration processor system utilizes a rotational mechanical gas displacement system 25 to transfer, meter, mix, and pressurize the various gasses. In the gas transformation process, ambient air is passed through an open flame gas-burner system to eliminate gasses and other present substances. Thereafter the non-combustible gas-mixture is cooled, filtered 30 for impurity removal, and mechanically mixed with a

pre-determined amount of hydrogen gas. There results a new synthetic gas. The synthetic gas formation stage also volume meters and determines the proper gas-mixing ratio for establishing the desired burn-rate of hydrogen gas. The rotational mechanical gas displacement system in that process determines the volume-amount of synthetic gas to be produced.

The above noted hydrogen aeration processor, of my co-pending patent application, is a multi stage system having utility in special applications. Whereas the hydrogen generator system of my other mentioned co-pending application does disclose a very simple and unique hydrogen generator.

In my co-pending patent application Ser. No. 315,945, filed Oct. 18, 1981 there is disclosed a combustion system having utility on a mechanical drive system. Particularly in one instance to drive a piston in an automotive device. There is shown a hydrogen generator for developing hydrogen gas, and perhaps other non-volatile gasses such as oxygen and nitrogen. The hydrogen gas with the attendant non-volatile gasses are fed via a line to a controlled air intake system. The combined hydrogen, non-volatile gasses, and the air after inter-mixing are fed to a combustion chamber where it is ignited. The exhaust gasses of the combustion chamber are returned in a closed loop arrangement to the mixing chamber for the mixture of volatile and non-combustible gasses. Particular applications and structural embodiments of the system are disclosed.

SUMMARY OF INVENTION:

The system of the present invention in its most preferred embodiment is for a combustion system utilizing hydrogen gas; particularly to drive a piston in an automobile device. The system utilizes a hydrogen generator for developing hydrogen gas. The hydrogen gas and other non-volatile gasses are fed to a mixing chamber also having oxygen fed thereto. The mixture is con-

trolled to regulate the burning temperature; that is, to lower the temperature velocity of the hydrogen gas to that of the commercial fuels. The hydrogen gas feed line to the combustion chamber includes a fine linear control gas flow valve. An air intake is the source of oxygen and it also includes a variable valve. The exhaust gasses from the combustion chamber are utilized in a controlled manner as the non-combustible gasses.

The hydrogen generator is improved upon to include a holding tank to provide a source of start-up fuel. Also, the hydrogen gas generator includes a switch to the power source operable from one position to another dependent upon a pressure sensing switch on the combustion chamber. The simplified structure includes a series of one-way valves, safety valves, and quenching apparatus. The combination of apparatus comprises the complete assembly for converting the standard automobile engine from gasoline (or other fuels) to the hydrogen gas mixture.

OBJECTS:

- It is accordingly a principal object of the present invention to provide a combustion system of gasses combined from a source of hydrogen and non-combustible gasses.

- Another object of the invention is to provide such a combustion system that intermixes the hydrogen and non-combustible gasses in a controlled manner and an thereby control the combustion temperature.

-

A further object of the invention is to provide such a combustion system that controls the fuel flow to the combustion chamber in s system and apparatus particularly adapted to hydrogen gas. Still other objects and features of the present invention will become apparent from the following detailed description when taken in conjunction with the drawings in which:

BRIEF DESCRIPTION OF DRAWINGS:

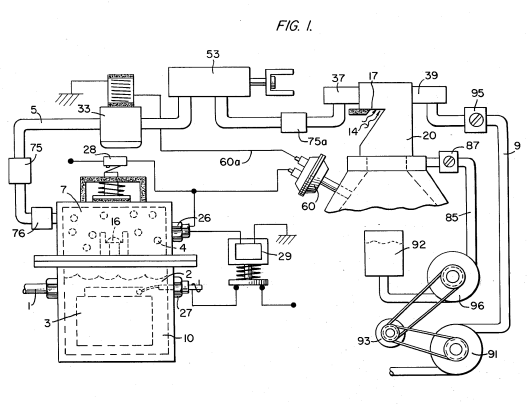

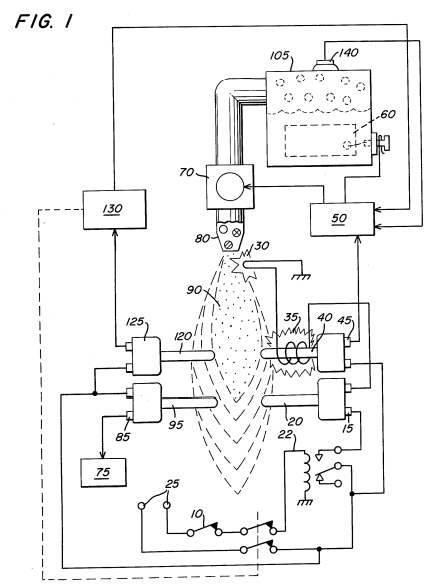

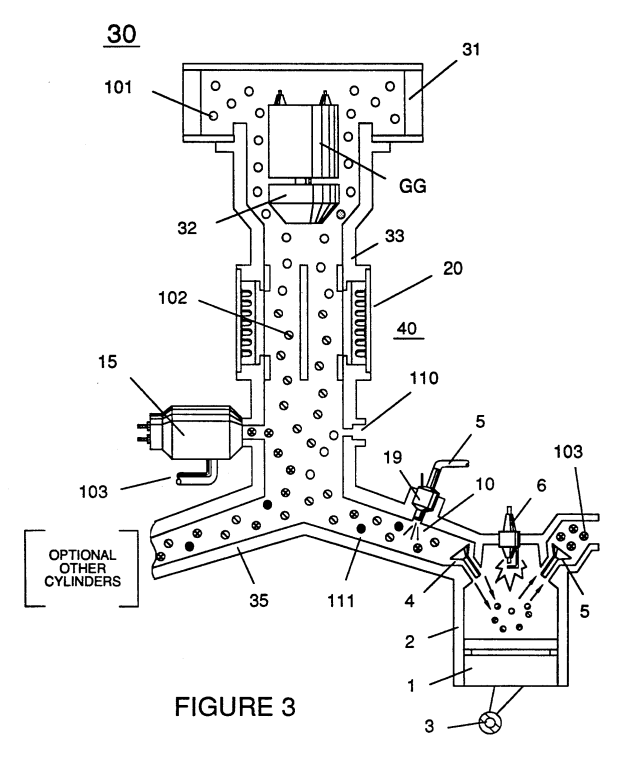

FIG. 1 is a mechanical schematic illustration partly in block form of the present invention in its most preferred embodiment.

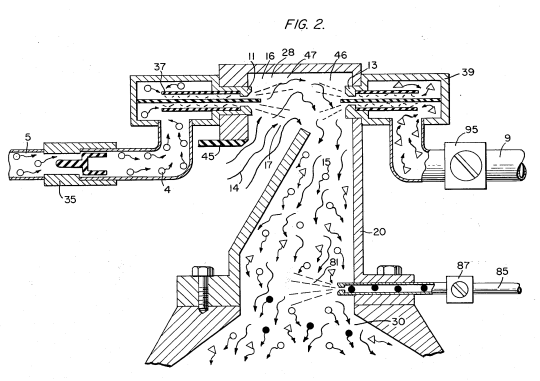

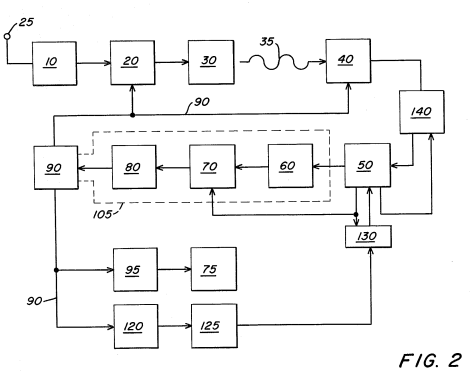

FIG. 2 is a block schematic illustration of the preferred embodiment of the hydrogen injector system of FIG. 1.

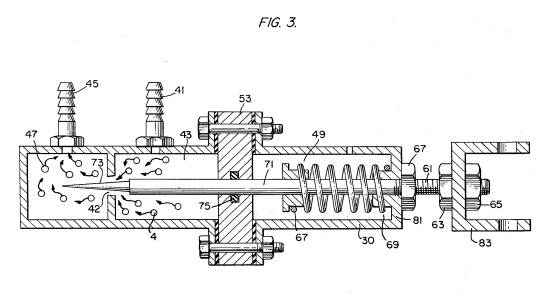

FIG. 3 is the fine linear fuel flow control shown in FIG. 1.

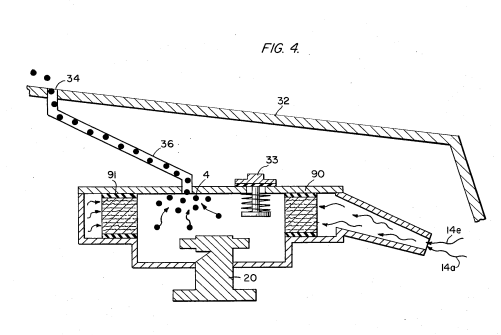

FIG. 4 is cross-sectional illustration of the complete fuel injector system in an automobile utilizing the concepts of the present invention.

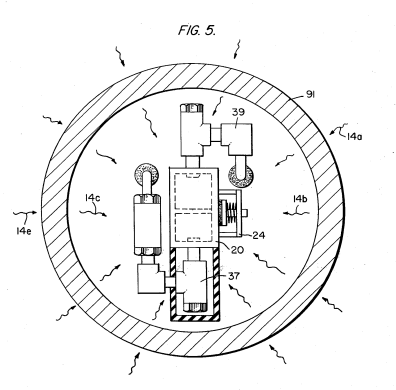

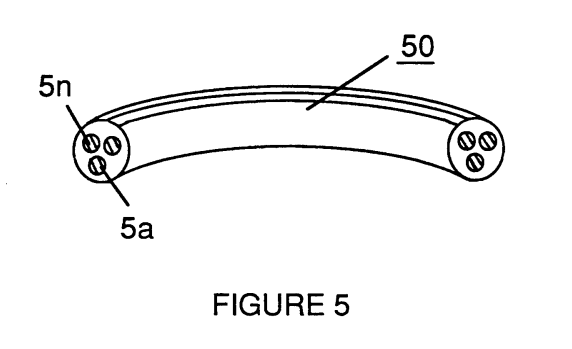

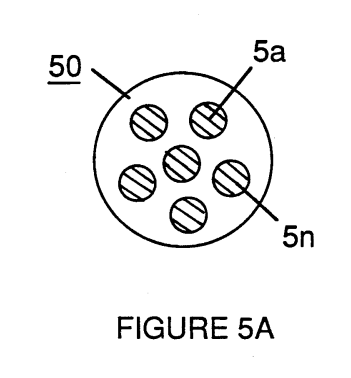

FIG. 5 is a schematic drawing in a top view of the fuel injector system utilized in the preferred embodiment.

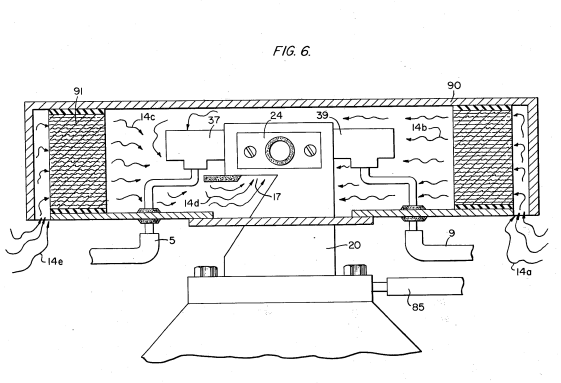

FIG. 6 is a cross-sectional side view of the fuel injector system in the present invention.

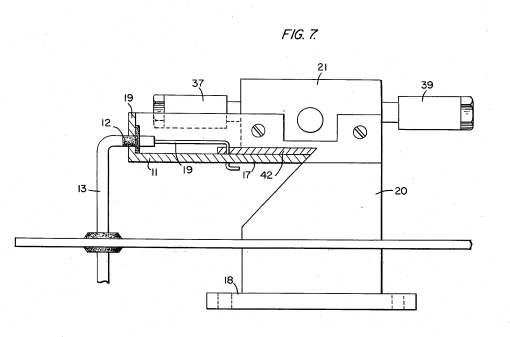

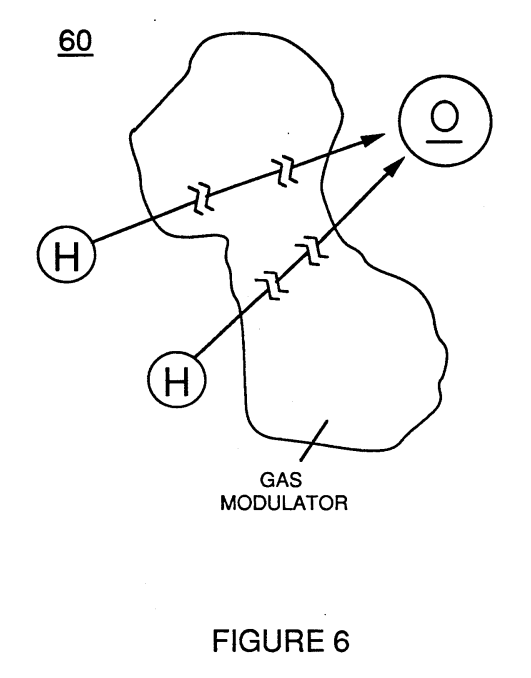

FIG. 7 is a side view of the fuel mixing chamber. 60

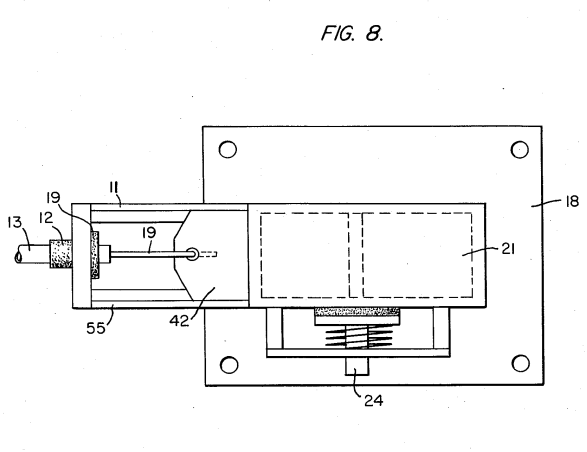

FIG. 8 is a top view of the air intake valve to fuel mixing chamber.

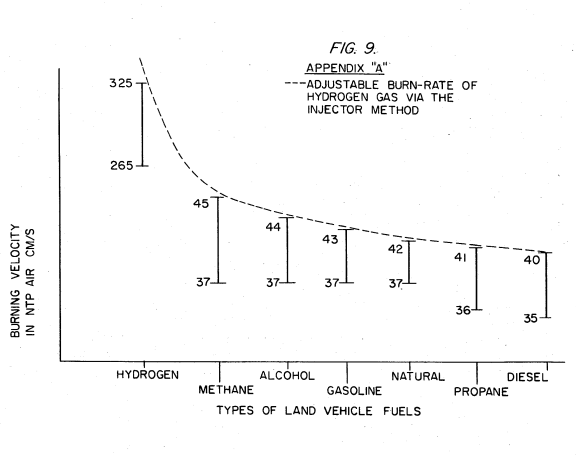

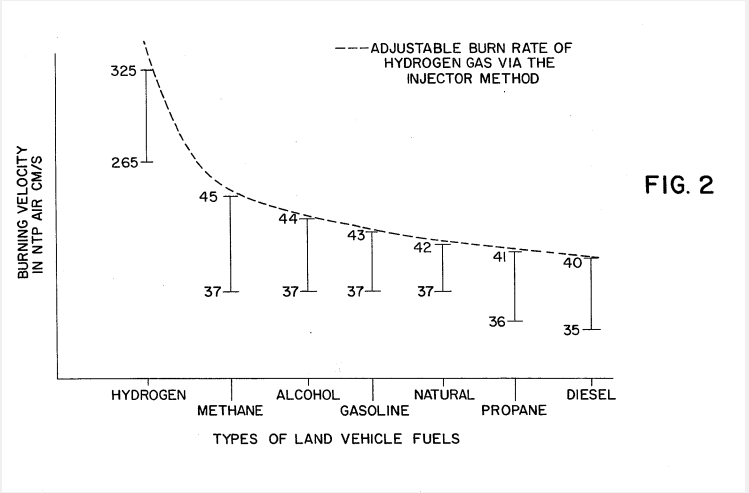

FIG. 9 is a comparison of the burning velocity of hydrogen with respect to other fuels.

DETAILED DESCRIPTION OF INVENTION TAKEN WITH DRAWINGS:

Referring to FIG. 1 the complete overall gas mixing and fuel flow system is illustrated together for utilization in a combustion engine particularly an engine utilized in an automobile.

With specific reference to FIG. 1, the hydrogen source 10 is the hydrogen generator disclosed and described in my co-pending application, supra. The container 10 is an enclosure for a water bath 2. Immersed in the water 2 is an array of plates 3 as further described in my co-pending application, supra. Applied to plates 3 is a source of direct current potential via electrical inlet 27. The upper portion 7 of the container 10 is a hydrogen storage area maintaining a predetermined amount of pressure. In this way for start up there will be an immediate flow of hydrogen gas. To replenish the expended water the generator provides a continuous

water source 1. Thereafter, the generator is operable as described in the aforesaid patent application.

The safety valve 28 is rupturable upon excessive gas build-up. Whereas the switch 26 is a gas pressure switch to maintain a predetermined gas pressure level about a regulated low-volume. The generated hydrogen gas 4 is fed from the one-

way check valve 16 via pipe 5 to a gas mixing chamber 20, wherein the hydrogen gas is inter-mixed with non-

combustible gasses via pipe line 9 from a source herein-after described.

In the event one way valve 75 should fail and there be a return spark that might ignite the hydrogen gas 4 in the storage area 7 of hydrogen generator 10, quenching assembly 76 will quench the spark and prevent such ignition. With particular reference to FIG. 2 the hydrogen gas via pipe line 5 and non-combustible gasses via pipe line 9 are fed to a carburetor (air-mixture) system 20 also

having an ambient air intake 14.

The hydrogen gas 4 is fed via line 5 through nozzle 11 in a spray 16 in to the trap area 46 of the mixing chamber 20. Nozzle 11 has an opening smaller than the plate openings in the quenching assembly 37, thereby preventing flash back in the event of sparking. The non-volatile gasses are injected into mixing chamber 20 trap area 47 in a jet spray 17 via nozzle 13. Quenching assembly 39 is operable much in the same manner as quenching assembly 37.

The ambient air is, in the preferred arrangement, the source of oxygen necessary for the combustion of the 45 hydrogen gas. Further, as disclosed in the aforesaid co-pending application the non-volatile gasses are in fact the exhaust gasses in a closed loop system. It is to be understood that the oxygen and/or the non-combustible gasses can be from an independent source.

With continued reference to FIG. 2 the gas trap area 47 is a predetermined size. In that hydrogen is lighter than air, the hydrogen will rise and become entrapped in the are 47. The size of area 47 is sufficient to contain enough hydrogen gas for instant ignition upon start up 55 of the combustion engine.

It will be noted that the hydrogen gas is injected in the uppermost region of the trap area 47. Hydrogen rises at a much greater velocity than oxygen or non-combustible gasses; perhaps three times or greater. Therefore, if the hydrogen gas entered the trap area 47 (mixing area) at its lowermost region the hydrogen gas would rise so rapidly that the air could not mix with the oxygen. With the structure shown in FIG. 2 of the trap area 47, the hydrogen gas is forced downwardly into the air intake 15. That is, the hydrogen gas is forced downwardly into the upwardly forced air and readily mixed therewith.

The ratio of the ambient air (oxygen) 14 and the non-combustible gas via line 9 is a controlled ratio and determined by the particular engine. Once the proper combustion rate is determined by the adjustment of valve 95 for varying the amount of the non-combustible gas and the adjustment of valve 45 for varying the amount of the ambient air, the ratio is maintained.

In a system wherein the non-combustible gasses are the exhaust gasses of the engine in a closed loop- arrangement, and wherein the air intake is under the control of the engine, the flow velocity and hence the air/non-combustible mixture, is maintained by the acceleration of the engine.

The mixture of air with non-combustible gasses becomes the carrier for the hydrogen gas. That is, the hydrogen gas is superimposed on the air/non-combustible mixture. By varying the amount of hydrogen gas superimposed on the air/non-combustible mixture, the r.p.m. of the engine is controlled. Reference is made to FIG. 3 illustrating precisely in a side view cross-section the fine linear fuel flow control The hydrogen gas 4 enters chamber 43 via gas inlet The hydrogen gas passes from chamber 43. The hydrogen gas passes from chamber 43 to chamber 47 via port or opening 42. The amount of gas passing form chamber 43 to chamber 47 is controlled by controlling the port opening 2.

The port opening is controlled by the insertion there through the linearly tapered pin 73. The blunt end of pin 73 is fixed to rod 71. rod 71 passed by supporting O-ring 75, through opening 81 in housing 30, to manual adjustment mechanism 83. The spring 49 retains the rod 71 is a fixed position relative to the pin 73 and opening 42. Upon actuating the mechanism 83, the pin 73 will recede from the opening 42 there by increasing the amount of gas passing from chamber 43 to chamber 47. The stops 67 and 69 maintain spring 49 in its stable position. The position of the pin 73 in a fixed position relative to opening 42 is adjusted via threaded nuts 63 and 67 on threaded rod 61. That is, the threaded adjustment controls the idle speed or permits the minimum

amount of gas to pass from chamber 43 to chamber 47 for continuous operation of the combustion engine.

Referring now to FIG. 8 there is illustrated the air adjustment control for manipulating the amount of air passing into the mixing chamber 20. The closure 21 mounted on plate 18 has an opening 17 on end 11 thereof. Slide-ability mounted over said opening 17 is a plate control 42. The position of the plate relative to the opening 17 is controlled by the position of the control rod 19 passing through a grommet 12 to control line. In event of malfunction that may cause combustion of gasses in mixing chamber 20, release valve 24 will rupture.

With reference now to FIG. 4, in the event hydrogen gas 4 should accumulate in the mixing chamber 20 to excessive pressure, an escape tube 36 connected to a port 34 on the automobile hood 32 permits the excess hydrogen gas to safely escape to the atmosphere. In the event of a malfunction that may cause combustion in the mixing chamber 20, the pressure relief valve 33 will

rupture expelling hydrogen gas without combustion. In the constructed arrangement of FIG. 1, there is illustrated a gas control system that may be retrofitted to an existing automobile internal combustion engine without changing or modifying automobile's design parameters or characteristics.

The flow of the hydrogen volatile gas is, of course, critical; therefore, there is incorporated in line 5 a gas flow valve 53 (FIG. 1) to adjust the hydrogen flow. Gas flow valve is described in detail with reference to FIG. 3. The intake air 14 may be in a carburetor arrangement with an intake adjustment 55 that adjusts the plate 42 opening and also more fully described with reference to

FIG. 8. To maintain constant pressure in hydrogen gas storage 7 in the on-off operation of the engine, the gas flow control valve is responsive to the electrical shut-off control 33. The constant pressure permits an abundant supply of gas on start up and during certain periods of running time in re-supply.

The switch 33 is in turn responsive to the vacuum control switch 60. During running of the engine vacuum will be built up which in turn leaves switch 33 open by contact with vacuum switch 60 through lead 60a. When the engine is not running the vacuum will de- 20 crease to zero and through switch 60 will cause electrical switch 33 to shut off cutting off the flow of hydrogen gas to the control valve 53. As low-voltage direct current is applied to safety valve 28, solenoid 29 is activated. The solenoid applies 25

a control voltage to the hydrogen generator exciter 3 via terminal 27 through pressure switch 26. As the electrical power activates electric solenoid 29, hydrogen gas is caused to pass through flow adjustment valve 16 and then outlet pipe 5 for utilization. The pressure differential hydrogen gas output to gas mixing chamber 20 is for example 30 lbs. to 15 lbs. Once hydrogen genera-

for 10 reaches an optimum gas pressure level, pressure 26 shuts off electrical power to the hydrogen exciters. exciters. If the chamber pressure exceeds a predeter-35 mined level, the safety release valve 28 is activated disconnecting the electrical current and thereby shutting down the entire system for safety inspection.

Hydrogen Gas Burner #4,421,474

PDF Download: Meyer #4,421,474 Hydrogen Gas Burner.pdf

CROSS REFERENCE:

The hydrogen/oxygen generator utilized in the present invention is that disclosed and claimed in my co- pending patent application, Ser. No.: 302,807, filed: Sept. 16, 1981, for HYDROGEN GENERATOR SYSTEM. In that process for separating hydrogen and oxygen atoms from water having impurities, the water is passed between two plates of similar non-oxidizing metal. No electrolyte is added to the water. The one plate has placed thereon a positive potential and the other a negative potential from a very low amperage direct-current power source. The sub-atomic action of the direct current voltage on the non-electrolytic water causes the hydrogen and oxygen atoms to be separated- —and similarly other gasses entrapped in the water such as nitrogen. The contaminants in the water that are not released are forced to disassociate themselves and may be collected or utilized and disposed of in a known manner.

The direct current acts as a static force on the water molecules; whereas the non-regulated rippling direct current acts as a dynamic force. Pulsating the direct current further enhances the release of the hydrogen and oxygen atoms from the water molecules.

In my co-pending patent application, Ser. No.: 262,744, filed: May 11, 1981, for: HYDROGEN AIR- DATION PROCESSOR, there is disclosed and claimed the utilization of the hydrogen/oxygen gas generator. In that system, the burn rate of the hydrogen gas is controlled by the controlled addition of non-combustible gasses to the mixture of hydrogen and oxygen gasses.

PRIOR ART:

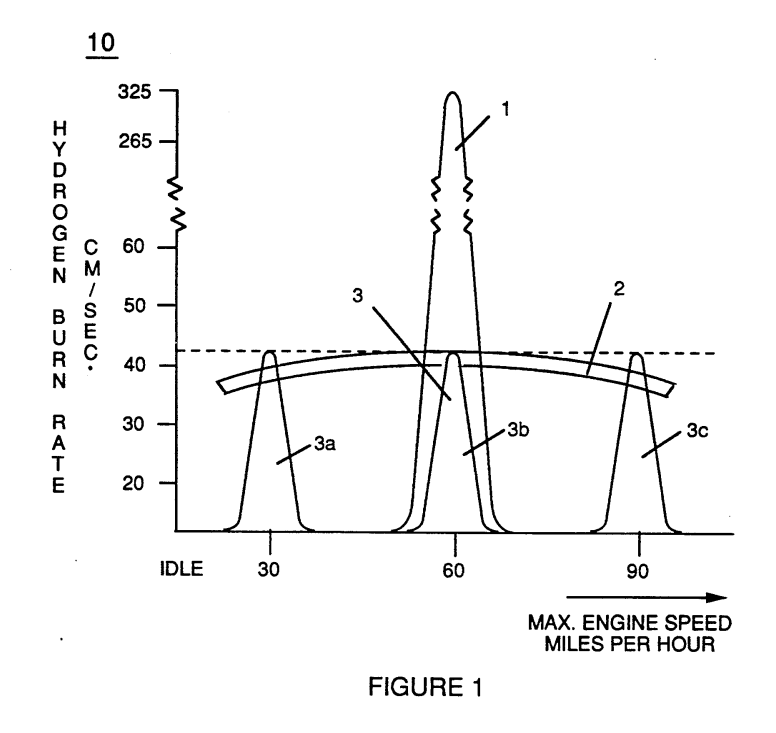

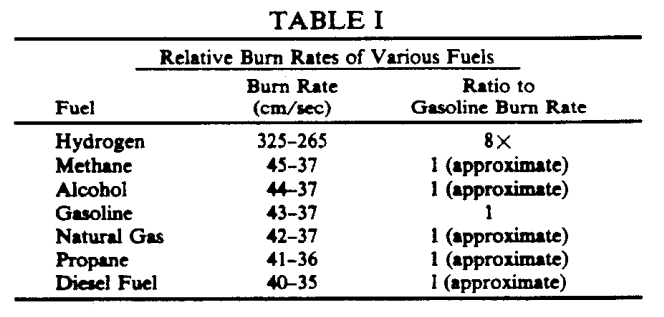

The electrolysis process for generating hydrogen and oxygen gas is well known in the art. It is, of course, further understood with a proper mixture of oxygen gas, the hydrogen gas is combustible and under ideal conditions a flame, may be had. Reference is made to USS. Pat. No.: 4,184,931. However, in that the burning velocity of hydrogen is 265-325 cm./sec. versus 37~45 cm./sec. of that of gasoline, the velocity of hydrogen is so great that the hydrogen ensuing from a nozzle will not under ordinary circumstances sustain a flame.

Therefore, to sustain a flame at a nozzle attached to a hydrogen generator the burning velocity of the hydro- gen gas must be reduced.

It has been found that all water in its natural state whether it be tap water, well water, sea water, or fresh water is a saturate of ambient air. Further, in that ambient air contains a substantial amount of nitrogen, all natural water will have entrapped therein nitrogen. Again, the percentage of nitrogen entrapped in natural water has been determined to be a fixed percentage and very uniform at seventeen (17%) percent—irrespective of the source of the water or its impurities. Hence, a natural water gas analysis will show a seventeen percent of nitrogen relative to the hydrogen and the oxygen.

The nozzle connected to the collection chamber via an appropriate line, has a port opening of a controlled size and configuration, related to the size of the flame and the temperature and velocity of the burning gas mixture. To maintain the flame, that is to prevent blown out, additional nozzles are included when the overall flame size is to be increased.

SUMMARY OF INVENTION:

The present invention is for a hydrogen gas burner and comprises a combustion chamber for the mixture of hydrogen gas, ambient air, and non-combustible gasses. The mixture of gasses is ignited and burns at a retarded velocity rate and temperature from that of hydrogen gas, but at a higher temperature rate than other gasses. The extremely narrow hydrogen gas mixture flame of very high temperature is restricted from the utilization means by a heat absorbing barrier. The flame strikes the barrier which in turn disperses the flame and absorbs the heat therefrom and thereafter radiates the heat as extremely hot air into the utilization means.

Positioned on the opposite side of the heat radiator/- barrier is a hot air trap. A small portion of the radiated heat is captured and returned to the combustion chamber as non-combustible gasses. Valve means in the re- turn line regulates the return of the non-combustible gas in a controlled amount to control the mixture. The present invention is. principally intended for use with the hydrogen generator of my co-pending patent application, supra; but it is not to be so limited and may be utilized with any other source of hydrogen gas.

OBJECTS:

- It is accordingly a principal object of the present application.to provide a hydrogen gas burner that has a temperature controlled flame and a heat radiator/barrier.

- Another object of the present invention is to provide a hydrogen gas burner that is capable of utilizing the heat from a confined high temperature flame.

- Another object of the present invention is to provide a hydrogen gas burner that is retarded from that of hydrogen gas, but above that of other gasses.

- Another object of the present invention is to provide a hydrogen gas burner that utilizes the exhaust air as non-combustible gas for mixture with the hydrogen gas.

- Another object of the present invention is to provide a hydrogen gas burner that is simple but rugged and most importantly safe for all intended purposes.

- Other objects and features of the present invention will become apparent from the following detailed description when taken in conjunction with the drawings in which:

BRIEF DESCRIPTION OF DRAWINGS:

- FIG. 1 is an overall cross-sectional view of the present invention in its most preferred embodiment.

- FIG. 2 is a graphical illustration of the burning of various standard fuels with that of hydrogen velocities.

DETAILED DESCRIPTION OF INVENTION:

With particular reference FIG. 1 there is illustrated in a schematic. cross-section the principals of the present invention.

Figure 1 is an overall cross-sectional view of the present invention in its most preferred embodiment.

The structure of the preferred embodiment comprises a housing 10, having an igniter 20 extending through the wall 11 thereof. A combustion chamber 60 positioned within the housing 10 has a first open end 62. A hydrogen gas 72 inlet 30 directs hydrogen gas via port 37 from a source 35 to the inlet 62 of the combustion chamber 68. Also directed to the same inlet 62, and assisted by flanges 64 and 66, is ambient air 70 entering through ports 13 in the housing 10. Adjacent the opposite end of the combustion chamber 60 the gas mixture 75 is ignited by the ignitor 20 to produce flame 77.

The velocity of the flame 77 causes it to strike and penetrate the barrier/radiator 50. The barrier 50 is of a material, such as metallic mesh or ceramic material, to disperse therein the flame and in turn become saturated with heat. The flame 77 is of a size sufficient to be dispersed throughout the barrier 50, but yet, not penetrate through the barrier 50. Radiated from the surface 52 of the barrier 50 is super-heated air 56 (gasses) to be passed on to a utilization device. Adjacent to surface 52 of barrier/radiator 50 is a hot air trap 40 with closed loop line 45 returning non-combustible gas 44 to the combustion chamber 60. Control valve 42 is intermediate the line 45.

In operation of the preferred embodiment hydrogen gas, 72, emitted from the nozzle 37 is directed to the combustion chamber 60. The flanges 64 and 66 on the open end of housing 63 of the combustion chamber 60 enlarges the open end of 62. In the enlargement ambient air from the opening 13 in the housing 10 is also directed to the combustion chamber 60. The ambient air and hydrogen traverses the opening 43 and further mixes with the non-combustible gas 44 from the closed loop line 45 with the hot air trap 40. The mixture of hydrogen gas 72, ambient air 70, and non-combustible gas 44, is ignited by the ignitor 20 having electrical electrodes 21 and 23. Upon ignition flame 77 ensues.

The mixture is controlled with each of three gasses. That is, the line 32 from the hydrogen source 35 has a valve 38 therein for controlling the amount of hydrogen 72 emitted from the nozzle 37. The opening 13 has a plate adjustment 15 for controlling the amount of ambient air 60 directed to the combustion chamber 60, and the closed-loop line has valve 42, as aforesaid, for con- trolling the amount of non-combustible gasses in the mixture. It can be appreciated that the temperature of the flame 77 and the velocity of the flame 77 is a function of the percentage of the various gasses in the mixture. Ina practical embodiment, the flame 70 temperature and velocity was substantially retarded from that of a hydrogen flame per se; but yet, much greater than the temperature and velocity of the flame from the gasses utilized in a conventional heating system.

To maintain a sufficient pressure for combustion of the hydrogen gas mixture with a minimum of pressure (for safety) and to limit blowout, the nozzle 37 opening 39 is extremely small. As a consequence, if the hydro- gen gas were burned directly from the nozzle 37, the flame would be finite in diameter. Further, its velocity would be so great it is questionable whether a flame could be sustained. The mixing of ambient air and non-combustible gas does enlarging the flame size and does reduce its velocity. However, to maintain a flame higher in temperature and velocity than the conventional gasses, the size and temperature of the flame is controlled by the aforementioned mixture. Therefore, to utilize the flame 77 in a present day utilization means, the flame is barred by the barrier 50. The barrier 50 is of a material that can absorb safely the intense flame 77 and thereafter radiate heat from its entire surface 52. The material 54 can be a ceramic, metallic mesh or other heat absorbing material known in the art. The radiated heat 56 is directed to the utilization means.

As aforesaid, the mixture of gasses that are burned include non-combustible gasses. As indicated in the above-noted co-pending patent applications, an excel- lent source of non-combustible gasses are exhaust gases. In this embodiment, the trap 50 entraps the hot air 74 and returns the same, through valve 42, to the combustion chamber 60 as non-combustible gas.

FIG. 2 is a graphical illustration of the burning of various standard fuels with that of hydrogen velocities.

With reference to FIG. 2 there is illustrated the burning velocity of various standard fuels. It can be seen the common type of fuel burns at a velocity substantially less than hydrogen gas. The ratio of hydrogen with non-combustible oxygen gasses is varied to obtain optimum burning velocity and temperature for the particular utilization. Once this is attained, the ratio, under normal conditions, will not be altered. Other uses having different fuel burn temperature and velocity will be adjusted in ratio of hydrogen- /oxygen to non-combustible gasses in the same manner as exemplified above.

Further, perhaps due to the hydrogen gas velocity, there will occur unburnt gas at the flame 77 output. The barrier 50, because of its material makeup will retard the movement and entrap the unspent hydrogen gas. As the superheated air 77 is dispersed within the material 54, the unspent hydrogen gas is ignited and burns therein. In this way the barrier 50 performs somewhat in the nature of an after burner.

CLAIMS:

1. A hydrogen gas burner for utilization as a heat source comprising:

- A housing having a double open-end combustion chamber positioned therein,

- A source of hydrogen gas and a nozzle connected thereto for directing the hydrogen gas into one end of said combustion chamber, ambient air intake means in said housing positioned to direct ambient air into said combustion chamber, and a source of a non-combustible gas, return line means for returning said non-combustible gas to said combustion chamber for mixing with said hydrogen gas and said ambient air, an ignitor for igniting said mixture of gasses,

- A barrier positioned adjacent to other open-end of said combustion chamber, said ignited mixture of gasses superheating the air in said housing and directing the same to said barrier, said barrier further comprising a heat dissipating surface to disperse heated air to the utilization means. :

2. The hydrogen gas burner of claim 1 wherein said source of non-combustible gas further comprises a hot air trap adjacent to the heat dissipating surface of said barrier and a return line from said trap to said combustion chamber.

3. The hydrogen gas burner of claim 1 wherein said return line further comprises valve means for control- ling the amount of non-combustible gas entering said combustion chamber.

4. The hydrogen gas burner of claim 1 wherein said ambient air intake means is positioned in said housing to provide ambient air to said combustion chamber together with said hydrogen gas.

5. The hydrogen gas burner of claim 1 wherein said ambient air intake means in said housing further comprises a valve means for controlling the amount of ambient air entering said combustion chamber.

6. The hydrogen gas burner of claim 1 wherein said source of hydrogen gas further comprises a valve means for controlling the amount of hydrogen gas introduced to said combustion chamber.

7. The hydrogen gas burner of claim 1 wherein said hydrogen gas, said ambient air, and said non-combustible gasses are controlled in amount to a predetermined ratio dependent upon the desired velocity and temperature of the ensuing flame.

8. The hydrogen gas burner of claim 1 wherein said nozzle has a port opening of a controlled size to provide a constant flame without blowout.

9. The hydrogen gas burner of claim 1 wherein said barrier comprising a heat saturating material with a heat dissipating surface.

10. The hydrogen gas burner of claim 9 wherein said heat absorbing/dissipating barrier comprises a ceramic material.

11. The hydrogen gas burner of claim 9 wherein said heat absorbing/dissipating barrier comprises a metallic mesh material. .

12. The hydrogen gas burner of claim 1 wherein said opening in said combustion chamber further comprises flange means for directing said hydrogen gas and said ambient air thereto. .

13. The hydrogen gas burner of claim 9 wherein said barrier retards unspent. hydrogen gas atoms and thereafter ignites the same.

StartUp ShutDown For A Hydrogen Gas Burner #4,465,455

PDF Download: Meyer #4,465,455 StartUp ShutDown For A Hydrogen Gas Burner.pdf

ABSTRACT:

System for flame start-up/shut-down for a hydrogen gas mixture burner. An electrical probe igniter positioned adjacent the gas port outlet. On demand the igniter is actuated to heat and electrically heat a thermal switch. Responsive electronic controls actuate the appropriate valves and circuits for operational start-up. Upon the ignition of the generated hydrogen gas mixture, a second thermal probe is heated by the flame to deactivate the ignition and start-up circuits. After demand the second thermal probe cools and the circuit is restored for start-up again. A safety probe positioned in the flame is quiescent. In the event of demand time shut-down, the safety probe will activate the circuits for restart. If failure to start-up continues for a predetermined time, the safety probe circuit will effect permanent shut-down.

CROSS REFERENCES:

In the non-electrolysis process disclosed and claimed in my co-pending patent application, Ser. No. 302,807, Filed: Sept. 16, 1981, For: HYDROGEN GENERATOR SYSTEM, for separating hydrogen and oxygen atoms from water, water is passed between two plates of similar non-oxidizing metal. The one plate has placed thereon a positive potential and the other a negative potential from a very low-direct-current power source. The sub-atomic action of the direct current voltage causes the hydrogen and oxygen atoms to be separated. The contaminants in the water are forced also to disassociate itself and may be collected or utilized and disposed of. This in turn lends the process to recombining the hydrogen and oxygen into pure water.

The direct current voltage applied to the plates is non-regulated and non-filtered. The direct current acts as a static force on the water molecules; whereas the rippling direct current voltage acts as a dynamic force. Pulsating the direct current further acts as a dynamic force and enhances considerably the splitting of the 25 atoms from the water molecules. An increase in voltage potential further increases the hydrogen output. Certain plate arrangements and configurations with graphical illustration or relative efficiency are disclosed.

In my co-pending patent application, Ser. No. 30 422,495, Filed: Sept. 24, 1982, For: PERIODIC FLUSH SYSTEM FOR NON-ELECTROLYSIS HYDROGEN GENERATOR, there is disclosed control apparatus and electrical circuitry for periodically shutting down the hydrogen generator for flushing out the 35 accumulated contaminates. The shut-down is in a sequential step-by-step operation. After the flushing is complete, the hydrogen generator is started up and, again, in a sequential step-by-step operation. Although the functions are numerous, the most critical is the 40 opening and closing of the gas valves, and the switching on and off of the electrical circuitry to the exciter elements.

BACKGROUND:

Heating and air environmental systems of the prior art have included sensing systems for flame-out, power loss or the like. These systems do provide some form of shut-down upon occurrence of a malfunction. However, the prior art systems are either of gas, oil, or electrical. Although a gas or oil furnace will utilize electrical circuitry for a blower, the energy, whether gas, oil, or electric, is supplied either by a utility or in bulk. None of the prior art systems generate the energy that is used in the heating or air control system. Accordingly, no monitoring systems for the generator systems are known in the prior art, that are applicable heating or air control systems.

SUMMARY OF INVENTION:

The present invention in its preferred embodiment provides a monitoring system and a start-up/shut-down circuitry and apparatus for a hydrogen gas burner. The system is distinctive in that the hydrogen generator is a demand system; that is, hydrogen gas is generated only when the thermostat (or other gauge) dictates the energy is needed. Accordingly, the start-up is the start-up of the energy generating system and thereafter starting the igniter to ignite the hydrogen gas mixture. Further, although the prior systems start-up on demand; none have a need for periodic shut-down.

The present invention is a start-up/shut-down system for an energy generator and for the utilization of the

energy generated. The function in addition to demand is periodic. Then, again, the same procedure is followed upon the occurrence of malfunction. The apparatus comprises an igniter in the flame path that upon actuation heats a thermal probe that controls the electrical/electronic circuitry for opening and closing the various controls and switches. Another probe deactivates the ignition and start-up upon completing the function. A safety probe positioned in the flame path is time controlled to start-up in the occurrence of a flame-out, if failure occurs in the attempt to retract within a given period of time the entire system is shut-down.

OBJECTS:

- It is a principal object of the present invention to provide a monitoring and control system for start-up and shut-down of an energy generator system.

- Another object of the present invention is to provide such a control system that is operable upon demand, periodically operable, and operable upon occurrence of a malfunction.

- A further object of the invention is for a monitoring and control system that distinguishes between an accidental flame-out and a flame-out caused by malfunction of the system.

- A further object of the invention is for a monitoring and control system that provides a restart function upon accidental flame-out. Other objects and features of the present invention will become apparent from the following detailed description when taken in conjunction with the drawings in which:

BRIEF DESCRIPTION OF DRAWINGS:

FIG. 1 schematically depicts a preferred embodiment of the invention of a hydrogen gas mixture burner incorporating the features of the invention.

FIG. 2 is a schematic block diagram of the preferred embodiment in a complete operational generator system.

DETAILED DESCRIPTION OF DRAWINGS:

With reference to FIG. 1 there is a illustrated schematically the mechanical/electrical apparatus of the system of the preferred embodiment of the invention taken in conjunction with the hydrogen generator of my co-pending patent application, supra. In FIG. 2 the electrical circuitry and actuating valves and the like are depicted in a sequential schematic block type of arrangement. Referring to FIG. 1, together with FIG. 2, the preferred embodiment of the present invention may now be described. the thermal probe switch 20, before start-up, is in a normally closed position. Upon the demand for energy, dictated by the thermostat 10 control, the relay 22 is closed, applying electrical power from source 25 to the electrical spark igniter 30 through the closed thermal probe 20. Upon the spark igniter 30 attaining the appropriate temperature, the radiant heat from coil 35 heats the thermal probe 40.

As the thermal probe 40 heats, the normally open switch 45 closes and in turn actuates the electrical control circuit 50. The control circuit 50 closes the circuit to apply electrical power to the exciters 60 in the non-electrolysis hydrogen generator 105. In sequence, and upon attaining appropriate pressure from the gasses generated as indicated by pressure valve in the hydrogen generator 105, also illustrated in FIG. 2 in dotted line block, the gas outlet valve 70 is opened, permitting gas to be expelled through a nozzle assembly 80. Upon the gas making contact with the heated electrical spark igniter 30, the hydrogen gas mixture, expelled from the controlled port opening in nozzle assembly 80 is ignited into a continuous extremely high temperature flame 90. The thermal probe 95 immediately begins to heat and after attaining the predetermined temperature the fan assembly 75 is actuated by the closure of relay 85.

The flame 90 having been ignited and burning, causes the thermal probe 20 to become heated and thereby opening its relay 15. In turn, the voltage applied to the electrical spark igniter 30 is terminated by the open relay 15. Upon the demand from the thermostat 10 being reached the relay 22 is opened thereby cutting off the voltage 25 to the thermal probe switch 20. Sequentially

the electrical control circuit 50 opens the circuit providing voltage to the exciters 60; thereby shutting gas outlet valve 70 to terminate the flame 90. Thereafter the circuit is ready for start-up again upon demand from the thermostat 10, as aforesaid.

A safety probe 120 is also positioned in the flame 90. During operation of the system under demand from the thermostat control 10, the probe 120 will remain heated. In this condition the attendant relay 130 is inoperative. If for some reason the flame 90 should be extinguished during the demand period the safety probe 120 will quickly cool and in sequence the attendant relay 130

will open. Relay 130 connected to relay 22 in the power circuit will act in place of the demand thermostat 10,that is, the relay 130 will override the demand thermostat 10. The circuits and functions will follow as above described for start-up in the event the flame-out was accidental.

The safety control system further includes a timer circuit and thermostat 125 that will permit the probe 120 to attain its temperature within a given period of time. If the probe 120 does not attain its temperature the same start-up procedure will follow again, within a given period of time. The timer 125 is so set that unless the probe 120 attains the appropriate temperature within the given period of time the entire circuitry is shut down permanently. This denotes a major failure in the system and not a simple flame-out. Finally, in the unlikely event of pressure build-up upon malfunction, there is provided a safety relief valve 140.

CLAIMS:

A start-up/shut/down circuit for activating and deactivating a non-ionic hydrogen generator burner system on demand, comprising:

- A thermostatic control demand circuit, a gas nozzle connected to the generated gas output of said hydrogen generator and a controlled size port in said nozzle for confining and controlling the hydrogen gas expelled therefrom,

- An igniter positioned in the projective path of said nozzle,

- An electrical heating element adjacent said igniter,

- A voltage source and means connected to said source for applying voltage to said heating element for heating said igniter upon demand as predetermined by said demand circuit,

- A heat sensing element, including heat responsive switching means, responsive to the temperature of said igniter electrical heating element,

- An electrical control circuit connected to said heat responsive switching means,

- A direct current voltage source and switching means for applying voltage from said voltage source to said hydrogen generator, said switch activated by said electrical control circuit upon said ignitor attaining a predetermined temperature, and gas valve outlet, and pressure sensing means on said hydrogen generator, said electrical control circuit, including means for actuating said outlet valve, to permit the generated gasses to be expelled from said nozzle upon said gasses generated by said hydrogen generator attaining a predetermined pressure, said expelled gasses from said nozzle, upon contact with said heated igniter, being ignited into a continuous flame,

- A second heat responsive sensory element positioned in the path of said ignited gasses including heat responsive switch means connected to said voltage source, disconnecting said voltage to said igniter electrical heating element upon said nozzle expelled gasses becoming ignited, and upon completion of demand, as predetermined by said demand circuit, said electrical control circuit disconnecting said direct current voltage to said hydrogen generator.

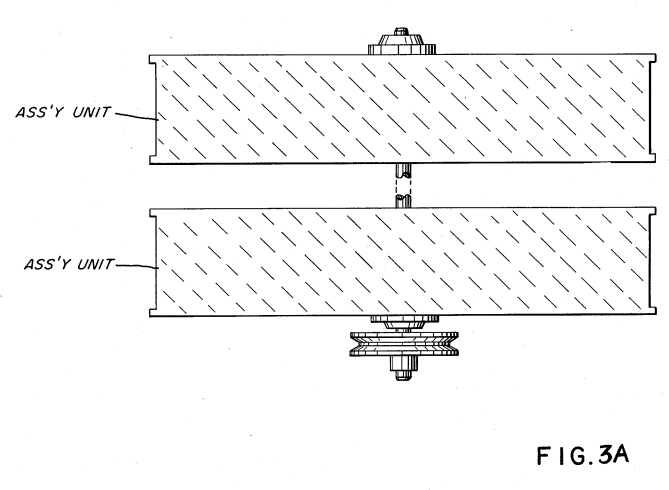

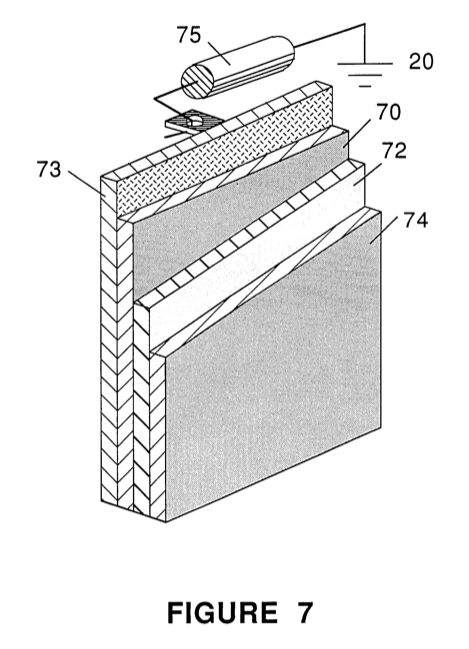

- A start-up/shut-down circuit for use in a hydrogen generator gas burner system as set forth in claim wherein said igniter is an electrical spark igniter, and wherein said heat sensing elements are thermal probes.

- A start-up/shut-down circuit for use in a hydrogen generator gas burner system as set forth in claim 1 further comprising an override switch connected to said second heat responsive sensory element for actuating said override switch to terminate said voltage source to said heating element upon the absence of a flame.

Gas Electrical Hydrogen Generator #4,613,304

United States Patent Patent Number: 4,613,304

Date of Patent: September 23, 1986GAS ELECTRICAL HYDROGEN GENERATOR

Inventor: Stanley A. Meyer, 3792 Broadway, Grove City, Ohio 43123

Filed: November 5, 1984

Application No.: 668,577

PDF Download: Meyer #4,613,304 Gas Electrical Hydrogen Generator.pdf

Abstract

A hydrogen gas generator system for converting water into hydrogen and oxygen gases, in combination with a magnetic particle accelerator for voltage/current electrical potential generation. The hydrogen gas generator encompasses an array of plates immersed in a housing and having natural water pass therethrough. Direct current, voltage dependant/current limited, potential applied to the plates causes the hydrogen/oxygen gases to disassociate from the water molecule. The upper portion of the container is a hydrogen/oxygen mixture collection chamber for maintaining a predetermined gas pressure. There is introduced into the hydrogen/oxygen collection chamber, from a source, a substantial quantity of permanently magnetically polarized particles. Attached to the gas collection chamber outlet is a non-magnetic, non-conductive closed loop of tubing. The polarized magnetic particles are caused to circulate in the closed loop tubing by an electrical and/or mechanical pump. A pick-up coil wound around the tubing will have a voltage induced therein as the magnetic field of the polarized magnetized gas particles pass therethrough. The induced voltage has utilization as an electrical power source. In that the hydrogen/oxygen gases are not polarized the gases will seek a pressure release via an outlet. The hydrogen and oxygen gases may be utilized such as in a burner system.

GAS ELECTRICAL HYDROGEN GENERATOR

This is a continuation-in-part application of Ser. No. 435,889, filed Oct. 21, 1982 now abandoned.

CROSS REFERENCE AND BACKGROUND

There is disclosed in my co-pending patent application, filed Sept. 16, 1981, U.S. Ser. No. 302,807, for Hydrogen Generator, a hydrogen generating system for a water bath having immersed therein an array of plates. The hydrogen and oxygen atoms are disassociated from the water molecule by the application of a regulated, non-filtered, i.e., voltage/current limited potential to the plates having natural water pass therethrough. The plates, as well as the housing, are non-oxidizing, non-corrosive, non-reactive, and of similar materials.

In my co-pending patent application, Ser. No. 411,797, for Controlled Hydrogen Gas Flame, filed Aug. 25, 1982, there is disclosed a hydrogen gas burner. The nozzle in the burner is connected to the storage container. The nozzle has an opening of a controlled size and configuration, related to the size of the flame and the refractive and velocity of the burning gas mixture.

Also, in my co-pending patent application, Ser. No. 367,061, for Electrical Hydrogen Generator, filed Apr. 4, 1982, there is disclosed an electrical generating system that is utilized in combination with the aforesaid hydrogen/oxygen generator.

OBJECTS

It is a principal object of the present invention to provide a hydrogen gas electrical generator capable of producing a voltage/current, much greater in magnitude heretofore possible.

Another object of the present invention is to provide such a hydrogen gas electrical generator utilizing magnetized elements and wherein the magnetized particles are accelerated in a closed loop tubing to induce a voltage/current much greater than heretofore possible.

An additional object of the present invention is to provide such an electrical generator in combination with a hydrogen/oxygen gas generator that is responsive to a simplified on-demand electrical generator.

SUMMARY OF INVENTION

The present invention utilizes the basic principle of inducing a magnetic current in a pick-up winding by passing a magnetized element in close proximity to the winding. In the present invention, a hydrogen/oxygen gas generator, in combination with an electrical generating system, provides for the on-demand generation of hydrogen/oxygen gases and the immediate utilization of the gases to provide electrical power.

The hydrogen gas generator encompasses an array of plates immersed in a housing and having natural water pass therethrough. Direct current, voltage dependent/current limited, applied to the plates causes the hydrogen/oxygen gases to disassociate from the water molecule. The upper portion of the container is a hydrogen/oxygen mixture collection chamber for maintaining a predetermined gas pressure. There is introduced into the hydrogen/oxygen collection chamber, from a source, a substantial quantity of permanently magnetically polarized particles. These particles are caused to circulate in the closed loop tubing by an electrical and/or mechanical pump. The magnetic fields of the polarized particles provide an attractive force for moving the polarized particles through the closed loop tubing. As the particles circulate through the closed loop tubing, a voltage is induced therein. This voltage has utilization as an electrical power source.

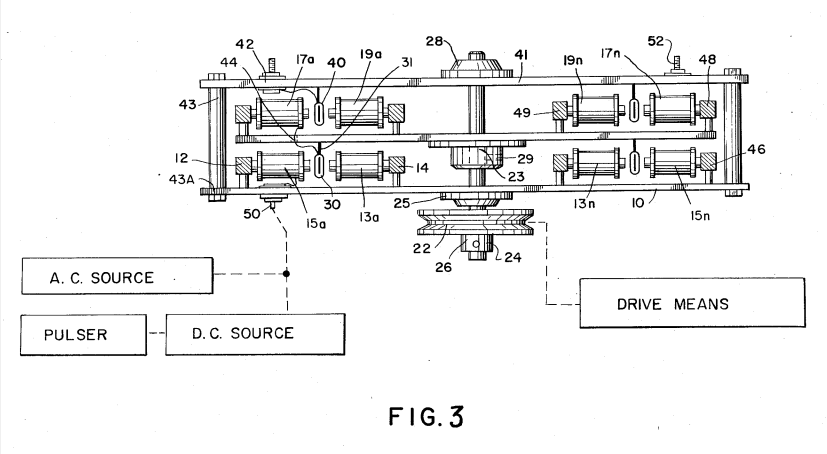

BRIEF DESCRIPTION OF DRAWINGS

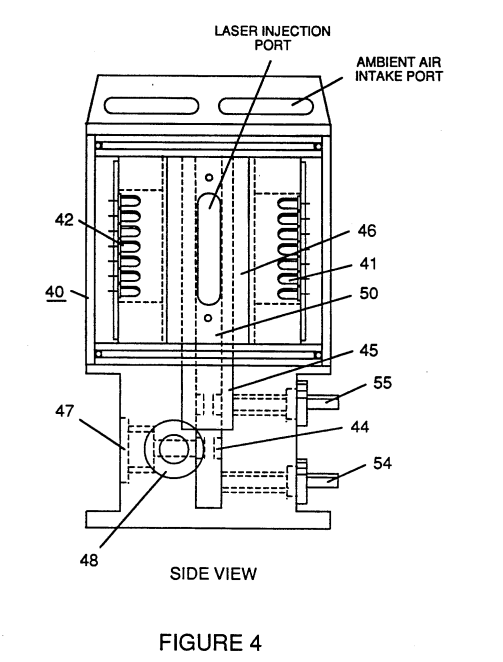

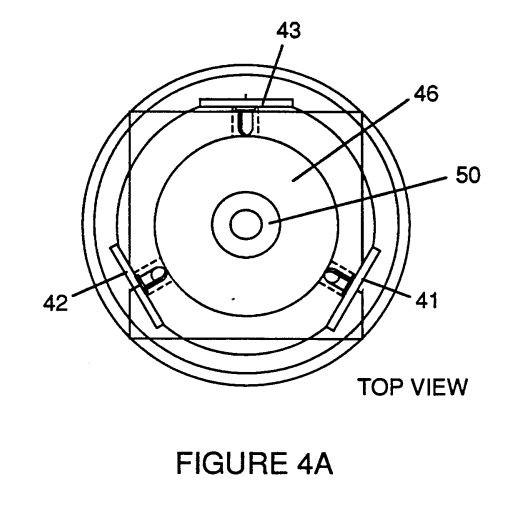

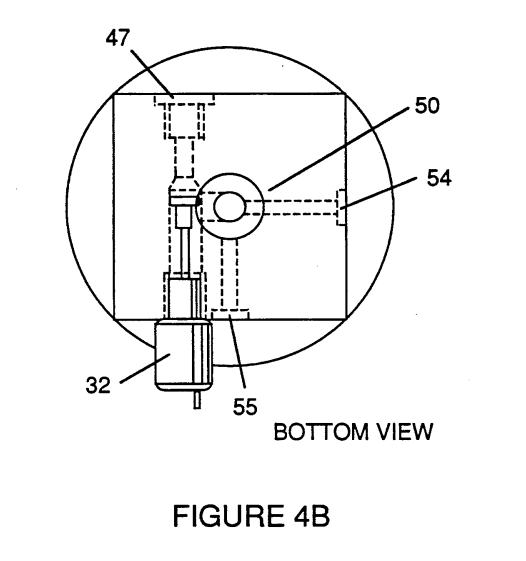

FIG. 1 is a simplified illustration of the principles of the invention, in cross-section showing the electrical generating means in combination with the hydrogen generator in a preferred embodiment.

FIG. 2 is a magnetic particle binding ring, in an electrical schematic circuit arrangement, illustrating the induced direct and alternating current voltage.

DETAILED DESCRIPTION OF DRAWINGS

Referring now to FIG. 1 there is illustrated the invention in a preferred embodiment in a simplified schematic arrangement. The generator 10 comprises an airtight pressure housing 12 of non-corrosive, non-reactive, non-oxidizing material. The housing 12 is filled with natural water 15 or a predetermined level, immersed in the water 12 is an array of plates 14.

In the preferred embodiment of the invention of FIG. 1, as disclosed in my co-pending application Ser. No. 302,807, the plates 14 are formed of an appropriate water flow, non-oxidizing, non-reactive material. A variable non-pulsed, voltage applying relay 17 connected to the plates 14 applies a steady d.c. current to the plates 14 which dissociates the water molecule as the natural water flows between the plates. An appropriate non-magnetic insulating material surrounds the plate configuration. Hydrogen/oxygen gas is formed and rises to the upper collection area 23 in the form of a hydrogen/oxygen gas mixture.

The gas collection area is connected by appropriate non-magnetic tubing 20 to the gas collection chamber 23. The chamber 23 is closed and connected to an outlet valve 27. A magnetic particle pump is utilized to pump the polarized magnetic particles through the closed loop tubing 24. These particles create a voltage in the windings 30 as they pass through the accelerator chamber 34.

The output voltage/current is utilized via terminals 70a-72.

As aforesaid, the storage chamber 23 is maintained at a predetermined pressure, and once the pressure is attained the hydrogen/oxygen gases will be expelled into outlet line 25 with a substantial velocity. The pressure releases and maintains consistency through the entire loop arrangement of storing gas.

Upon demand for the flame, (such as for burning) from demand circuit 66, the valve 37 is opened causing the 10 gases circulating in closed loop line 24 to be released into the nozzle 40 and provide the flame 45 for ignition.

The hydrogen/oxygen gases leave the particles suspended through this system and the magnetic fields hold the fields of polarized particles via the attractive force, the motion of the polarized particles through the closed loop 78 will be greater than the gas stream of hydrogen/oxygen. This will enable the oxygen from the hydrogen/oxygen gas as well as separate themselves from the polarized particles. The hydrogen/oxygen gases will go via 35 to nozzle 40 whereas the polarized particles will continue to circulate through the closed loop. The chamber 37 further includes the main system 75 with the electrical source 16 to the generator system as the pressure in the chamber 23 sensed by pressure sensor 69 achieves a predetermined level.

By this description of the hydrogen generator as a burner, as disclosed in the co-pending patent application Ser. No. 411,997, the outlet tube 26 is connected to 30 directly to the nozzle 40 to obtain the flame 45 upon ignition. The operation of the gas burner is not altered in the present invention.

The housing 15 further comprises an inlet 34 having 35 a chamber 33 of substantial amount of permanently polarized magnetic particles size 30X36. The chamber 23 superimposes the non-electrically conducting gas and hydrogen/oxygen gases.

Upon demand, as set forth before, the opening of the 40 valve 37 causes the pressurized differential with the gases circulating in the chamber 23. In this way the gases being the polarized particles superimposed therein will be greater released and caused to enter the closed-loop 50.

The gases will have accelerated gas 45 maintain in a continuous motion circulating through the closed loop.

The magnetized particle 35 is a series of loops of non-conducting tubing 25 wherein the tubing configuration in an enclosure is in spaced relationship of 50 magnetic induction units.

In the illustration the gas maintaining its superimposed polarized fields is the key for obtaining high-energy use in many of these systems as will be understood.

The gas enclosed in this chamber is critical as it is not operating as the system for the current usage of 35. It is critical for the same expansion of this model 35, however upon entry into the nozzle 40 it can be placed for use.

Upon satisfaction of demand, the valve 37 will close and thereby close the current circulating through closed-loop 24. In this arrangement the chamber 23 via closed-loop line 42, this arrangement the pump 45 will continue to operate and cause a continuous circulation of the polarized particles through the closed loop. Upon cessation of demand of current, the pressure release will shut off the system via 74.

The hydrogen/oxygen gas mixture demand circuit generates the superimposed polarized magnetic particles. The pump 45 is continuous upon this as a part of the continuous operation of the hydrogen/oxygen system.

The magnetized particle source 32 is operative on demand in the main generator assembly to maintain this system. The hydrogen/oxygen gases are superimposed through a nozzle 45 generating this flame system in the hydrogen/oxygen gas.

Referring now again to FIG. 1 there is illustrated initially a schematic system of this combination of demand, electrical control, and output of power.

Initially it is noted that the pump 45 of FIG. 1 has been replaced by the electrical particle accelerator 46. The accelerator 46 is non-mechanical, no moving part element and therefore not subject to wear. It is to be recalled, polarized particles have been placed on the magnetic particle accelerator 46 for the magnetic particles to be forced along the accelerator and they are to 40 pass through the center of the accelerator where they feed the system.

The accelerator system of FIG. 2 is used in FIG. 1 for the acceleration of 46-FIG. 2 may be utilized as both the induced current voltage, or alternating current winding on 60.

Both the accelerator 46 and the pump assembly 45 with reference to FIG. 2 illustrates the simplicity of the electrical system to induce the voltage for maximum usage as the 10 main winding 64 on alternating windings wound in parallel for obtaining an electrical field.

The combination electrical field generates the polarity needed and magnetized with the voltage is utilized on pickup coil windings via the pump.

With reference to FIG. 1 with continued reference applied to the plates 14 a direct current voltage. The voltage applied to the plates 14 from power supply 16, depending upon the demand circuit, will vary the intensity of the flame 45, the voltage of the generator, and the output.

Further, as specifically repeated, the voltage is current limited. Accordingly, the power source 16 will provide circuitry for varying the voltage to the plates 14 and for restricting the amperage to a negligible value relative to said voltage.

voltage applied to the plates 14 from power supply 16, depending upon the intensity of the generator, may be a variable voltage. For instance, if it is desired to vary the intensity of the flame 45, the voltage at the plates 14 will be varied.

Further, as specifically repeated, the voltage is current limited. Accordingly, the power source 16 will provide circuitry for varying the voltage to the plates 14 and for restricting the amperage to a negligible value relative to said voltage.

In a self-sustaining embodiment of the gas electrical generator, a portion of the output at the voltage taps 70–72 of the pickup coils is directed back to the power supply 16. In that the total power requested to be applied to the plates 14 is relatively low, an insignificant portion of the output at gas taps 70–72 is required for sustained operation of the system.

The electrical particle portion of the electrical gas generator of the present invention is operative continuously as set forth above. Hence the output voltage at gas taps 70–72 will be available to the power supply 16 whenever a demand for gas generation is made.

I claim:

- In combination, a hydrogen/oxygen generator comprising:

a hydrogen/oxygen generator including a housing having a gas collection chamber for maintaining a preset volume of gas therein under pressure, an outlet attached to said collection chamber, a non-magnetic tubing connected to the other end of said gas collection chamber and said collection chamber in a closed loop,

utilization means, and

a Y type of connector alternately connecting said gas line tubing to said utilization means and said collection chamber,

an inlet means attached to said gas collection chamber,

a source of permanently magnetized polarized particles connected to said inlet and wherein said particles are superimposed on said hydrogen and said particles pass through said tubing and said non-magnetic tubing connected to said hydrogen/oxygen gases.

- The combination as set forth in claim 1 further comprising:

two directional valve means, and

a demand circuit connected to said valve means for selectively closing and opening said valves so said utilization means and gases having superimposed hydrogen/oxygen particles pass therethrough,

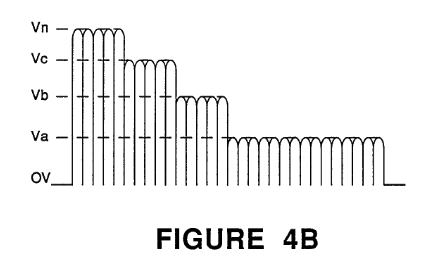

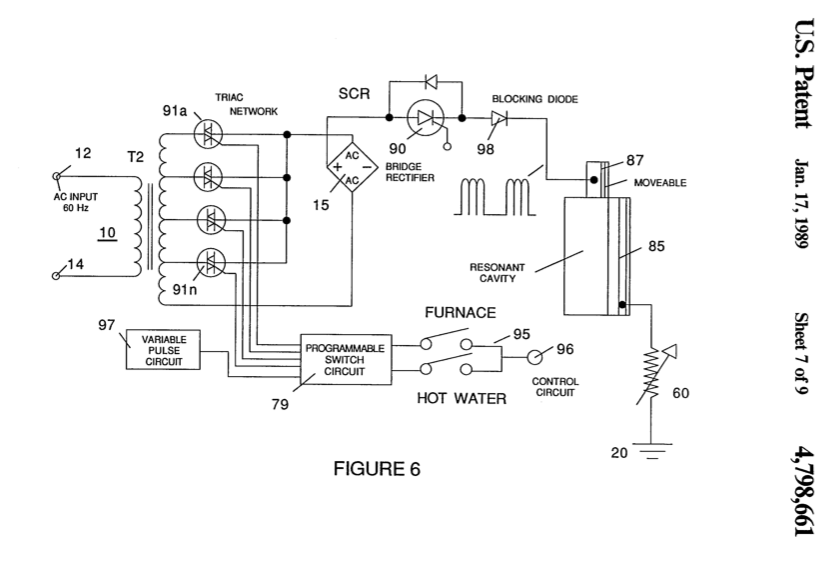

a pressure gauge for determining the pressure in said collection chamber,