EPG Speculations/Suggestions

*** Page will be continually updated.

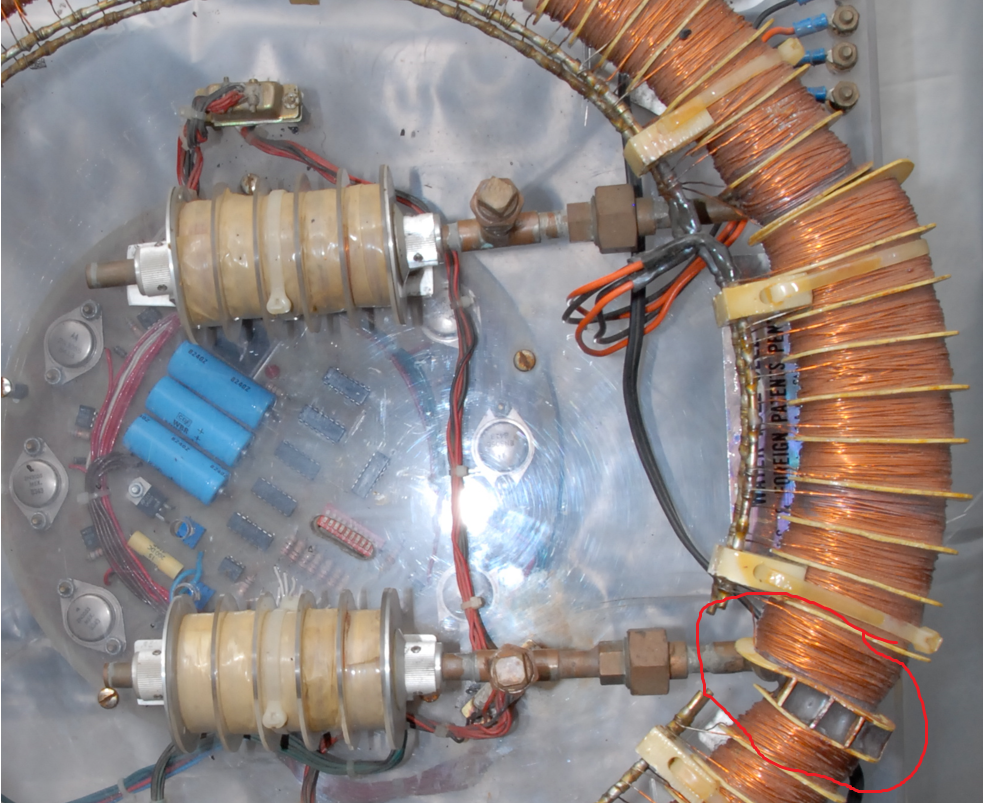

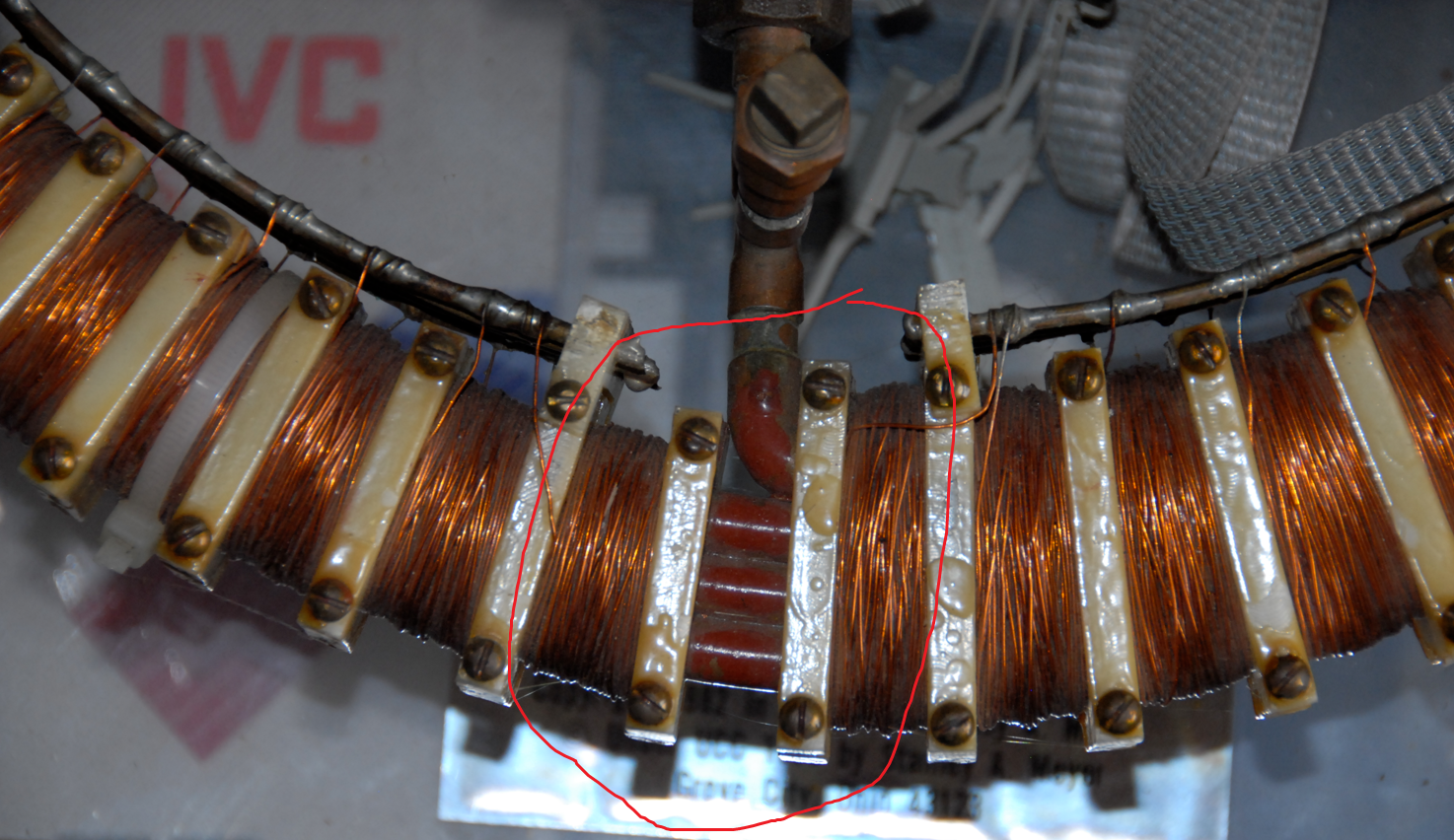

Highlighted below, appears to be various, thick varnishing applied to outer surface of copper tubing on each EPG model. Figure 3 demonstrates the best example of this. Obviously, this was done to insulate adjacent tubing during operation. However, this could also provide further proof of magnetizing media using pickup coil array (please see other page in this section covering this topic).

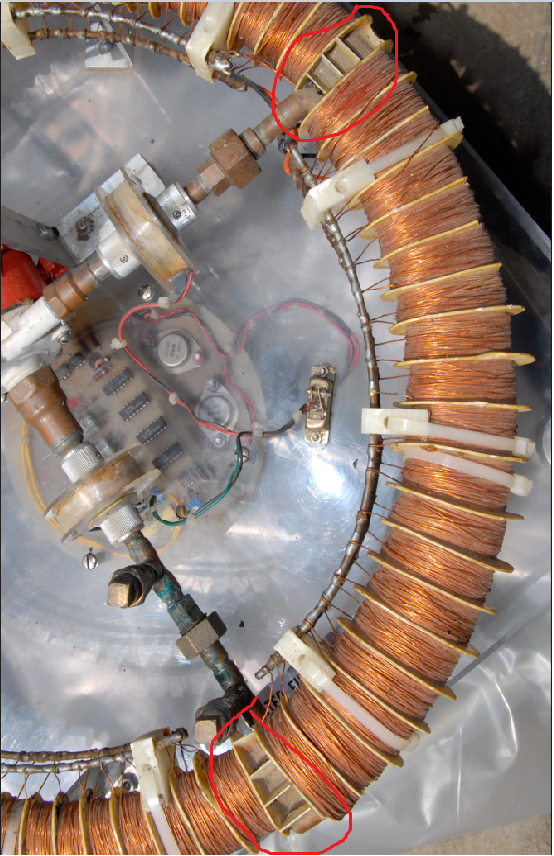

Seen in the circled red area is dividers. It appears these dividers are placed in this location to provide support for pickup coils wound on opposite sides. This area being where the 90 degree fittings are attached couldn't receive pickup coils.

Figure 1: Mechanical pump EPG

Figure 2: Electromagnetic Push-Pull EPG ("Magnetic Spin Generator")

Figure 3: Electromagnetic linear pump EPG

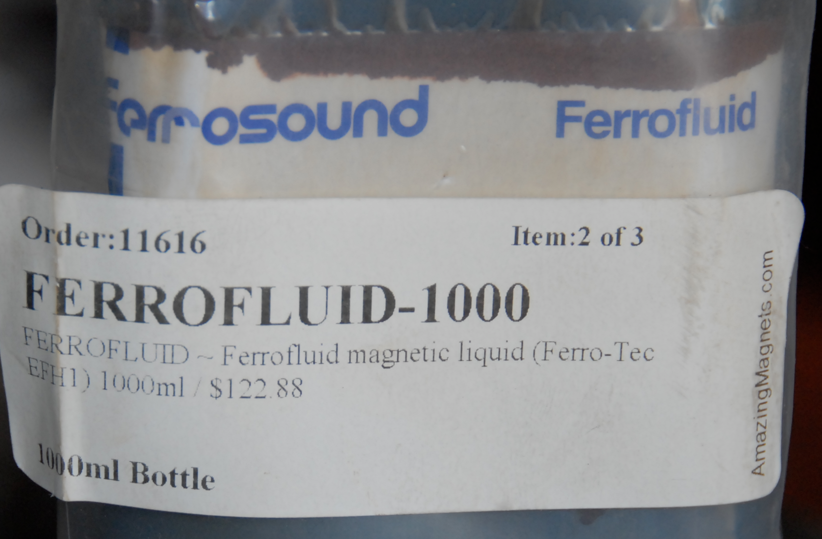

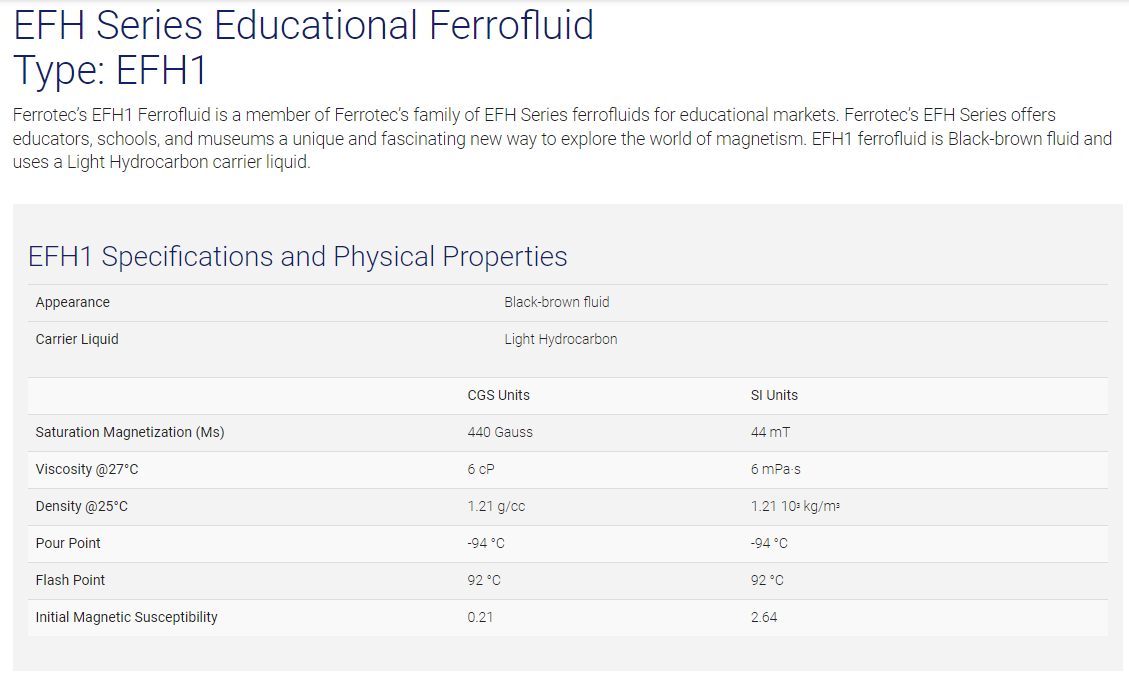

Above, the green residue spillage seen on copper tubing has been speculated to be Copper Oleate. Oleic acid is utilized in the production of ferrofluid, typically used as a surfactant for separating iron particles. We know that ferrofluid was found at the estate sale, as shown below. Type is EFH1. EFH-1 criteria below was from Ferrotech website: FerroTech EFH-1