JP59038525A - Water/Hydrogen Gas/Oxygen Gas Generator with Controlled Flame of Hydrogen Gas

Japan Patent Office (JP)

Publication of Patent Application (A)

Publication Number: Showa 59-38525

Publication Date: Showa 59 (1984) March 2

Application Number: Showa 58 (1983) Number 23665

Title of the Invention:

Water/Hydrogen Gas/Oxygen Gas Generator with Controlled Flame of Hydrogen GasApplicant:

Stanley A. Meyer

3792 Broadway, Grove City, Ohio 43123, USAPriority Claim:

Filed on August 25, 1982, in the United States

Application Number: 411977Agent:

Attorney Nakamura Tetsu

(With 4 assistants)

Detailed Description of the Invention

1. Title of the Invention:

Water/Hydrogen Gas/Oxygen Gas Generator with Controlled Flame of Hydrogen Gas

2. Scope of the Patent Claim:

(1) A water/hydrogen gas/oxygen gas generator that produces these gases while controlling and maintaining the flame produced by hydrogen gas. This apparatus uses a low voltage, low current, and low frequency applied to a pair of stainless-steel electrodes positioned in water to separate water into hydrogen and oxygen gases. Moreover, it uses a gas collection mechanism to retrieve the non-combustible materials and water vapor. Additionally, the invention includes a mechanism to mix the hydrogen gas with water vapor and non-combustible gases before introducing them into the combustion chamber. The size and shape of the nozzle determines the amount of gas delivered, and the system incorporates a mechanism to regulate the combustion flame of the hydrogen gas.

(2) A water/hydrogen gas/oxygen gas generator as described in claim (1), wherein the non-combustible gas is compressed and mixed with the hydrogen gas and oxygen gas.

(3) A water/hydrogen gas/oxygen gas generator as described in claim (2), where the gas mixing mechanism further includes a chamber for mixing hydrogen gas, oxygen gas, and non-combustible gases with water vapor and non-combustible gas, allowing for a controlled mixture.

(4) A water/hydrogen gas/oxygen gas generator as described in claim (3), wherein the chamber includes an inlet to control the flow of gases into the chamber and a mechanism for further regulating the mixture to produce an optimal flame.

(5) A water/hydrogen gas/oxygen gas generator as described in claim (4), wherein the nozzle has a specific size and shape to control the output of the gas mixture, and the size of the flame is determined by the nozzle.

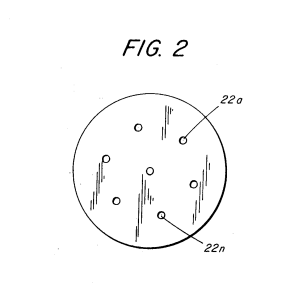

(6) A water/hydrogen gas/oxygen gas generator as described in claim (5), where the size and shape of the nozzle is maintained by multiple ports, allowing the flame size to be proportionally enlarged.

(7) A water/hydrogen gas/oxygen gas generator as described in claim (6), where the port size and shape are maintained by multiple ports, enabling the flame to be enlarged in proportion to the size.

3. Detailed Description of the Invention

This invention pertains to a water/hydrogen gas/oxygen gas generation apparatus.

The method described in U.S. Patent 302,807 (dated September 6, 1981), also employed in this invention, involves generating hydrogen and oxygen gases from water.

The method described uses conductive metal plates with non-oxidizing properties to separate hydrogen atoms from water molecules. These metal plates are exposed to low-voltage, low-current, and low-frequency electric fields to destabilize the water molecules, allowing the hydrogen and oxygen atoms to separate. This induces a sub-atomic (sub-atomic) reaction, allowing the release of hydrogen and oxygen atoms from water. The hydrogen atom is separated from the oxygen atom and is then released as hydrogen gas, which is collected by the gas recovery system.

The energy required for this process is supplied by an electric field, where the attraction force acts on the hydrogen gas, drawing it toward the plates. Meanwhile, the separated gas is drawn into the recovery system.

The separated hydrogen gas is then used as a fuel, functioning through the application of low-energy electric fields.

(dynamic) and serves to transform the hydrogen and oxygen atoms into molecules. The excitation from water molecules increases the vibration of the hydrogen and oxygen atoms.

The apparatus disclosed in U.S. Patent 2,662,244 (dated May 1, 1953) describes a water/hydrogen/oxygen gas generation device using a certain method to produce hydrogen and oxygen gases.

In the process, an electric field is applied to water, and the excitation generated allows the hydrogen and oxygen atoms to separate. This method generates a flame and is designed to produce flames by utilizing these separated gases.

When used, the device must ensure that water is constantly replenished to maintain a steady flow of hydrogen gas. The output can be controlled to vary from approximately 3 to 5 cm/sec. This rate can be adjusted based on operational parameters.

The hydrogen gas generated is collected using specific mechanisms to ensure that no unnecessary gases are trapped. Thus, the generated hydrogen gas is systematically fed into the intended systems.

To maintain the flame, it is necessary to carefully control the water flow in order to minimize the presence of excess water vapor.

Water naturally exists in various forms, such as distilled water, brine, seawater, and fresh water, but it is important to know how to prepare water to achieve optimal conditions for the system being used. Additionally, in this case, the mixture should include a sufficient amount of hydrogen and oxygen gases to ensure that the natural properties of water do not interfere with the output from the apparatus.

The generated gas is collected via lines connected to collection channels, ensuring that the size of the hydrogen gas generated is appropriate for the intended applications. This can be achieved by adjusting the input conditions to regulate the size and shape of the gas output.

The primary goal of this system is to utilize water as the primary material for generating hydrogen gas.

In addition to hydrogen and oxygen, this system can also supply fresh water/hydrogen gas generation, making it possible to maintain combustion using these gases.

Another objective of this invention is to provide hydrogen gas and oxygen gas to create a new type of water/hydrogen gas generation system, which helps minimize the combustion of other non-hydrogen gases.

The primary goal of this invention is to provide a means for generating non-hydrogen gas by supplying water and oxygen, and then using the energy produced to maintain combustion.

In the present example, the device described will be explained in detail below. The hydrogen and oxygen generated will be combined to provide a combustible mixture.

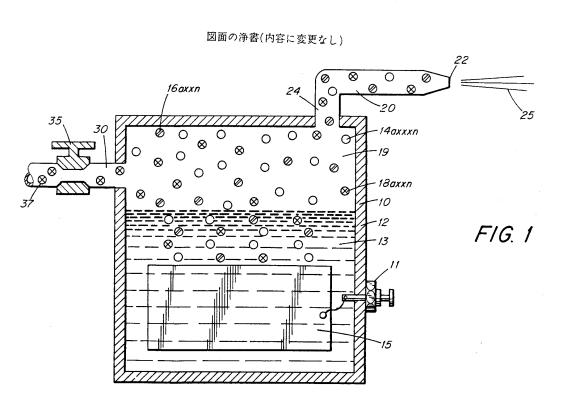

In the configuration illustrated in this example, the output from the generating device is introduced into a reaction chamber where the generated gases will be processed. The processed output will then be directed to a nozzle for application.

The power is supplied through the electrodes of the generator, which are connected to the output terminals. In this manner, the hydrogen and oxygen will be combined within a reaction chamber that is located above the electrodes.

Furthermore, the methods of maintaining the combination of hydrogen and oxygen in this chamber are essential, as they need to be continuously supplied to ensure efficient combustion. The system requires specific management of these gases to maintain stability.

Natural water sources, such as rivers, lakes, or oceans, can be utilized in this system. Additionally, the use of a spray atomizer is preferred, which aids in the effective integration of hydrogen and oxygen gases for combustion purposes.

The system described utilizes various methodologies to ensure that the gases are effectively combined and delivered for optimal energy production. Therefore, it is crucial to maintain the specific conditions necessary for the effective operation of this innovative water/hydrogen gas generation technology.

In this way, hydrogen gas and oxygen gas are generated and burned together with the water gas.

An example of using water is when water is introduced into the reactor at channel 16. Here, hydrogen gas produced in the generator 10 at inlet 18 is mixed with oxygen gas from channel 18.

Next, gas is passed through line 20 and valve 22, allowing it to flow and mixing the gases, yielding a combined gas mixture, which is held under a pressure of approximately 25.

In conjunction with the water flowing through channel 14, the water vapor will further enhance the production of hydrogen gas, effectively increasing the efficiency of the process. The addition of water to the hydrogen gas system within the generator channel 19 assists in reducing impurities in the gas.

The nozzle 20 is connected to the generator 10 through line 24 and channel 19, allowing for gas to be drawn from the reservoir at port 22. The pressure of the gas within the channel 19 is maintained at a considerable level.

However, the amount of gas that can be produced in this manner is limited. Therefore, it is crucial to consider the potential for introducing water vapor. Additionally, if water is allowed to flow into the system, it will carry with it a mixture of gaseous and liquid components.

Moreover, water will enhance the process and facilitate the mixing of gases. The overall effect is that the gas pressure can be increased, thereby improving the efficiency of the gas generation system.

The pressure is directly related to the amount of power generated.

The pressure of the water, which contains the gas in channel 19, can increase. However, the effectiveness of this increase is tied to the capacity of port 22. It is uncertain whether the pressure that can be achieved is sufficient to maintain the desired outcomes. Nevertheless, if the port is reduced, the system can produce a higher concentration of gas.

Additionally, if the pressure increases significantly, it may result in a larger quantity of gas being produced. Ports that have specific targets, such as port 22, are crucial for controlling the flow. If necessary, adjustments can be made to maintain appropriate levels, ensuring that sufficient conditions for gas production are met.

Detailed Description of the Invention

This invention relates to a device that generates hydrogen gas and oxygen gas by electrolysis of water. This invention is related to U.S. Patent No. 302,807 (issued on June 6, 1981), which pertains to methods of generating hydrogen gas and oxygen gas for use in various applications.

In the prior art, methods for generating hydrogen and oxygen gases by electrolysis have been developed, using certain methods that introduce water molecules, thereby separating the two types of gas. The method outlined in this invention uses the above to effectively generate hydrogen and oxygen gas.

The specific components involved in the electrolysis process of water, and the hydrogen and oxygen gases produced from this process are detailed in the following.

- The apparatus includes a basic electrolytic chamber for generating hydrogen and oxygen gas.

- The electrolytic chamber can vary in size and shape and may utilize various types of electrodes.

- It has been shown that using non-ionic water and certain catalysts can improve the efficiency of the process.

- The characteristics of the hydrogen and oxygen gases produced by the method described can vary based on conditions like temperature and pressure.

Supplementary Correction Document (Format)

1. Title of Application: Apparatus for generating hydrogen/oxygen gas from water

2. Document Number: Showa 58 (1983) Special No. 23667

3. Corrected by: Applicant

Name: Stanley Meyer

4. Representative:

Address: 4312, Hawaii, USA, Kaimuki, P.O. Box 9879

5. Date of Correction Request: Showa 58 (1983) March 3

6. Scope of Correction: All illustrations

7. Content of Correction: A detailed description of the content of the illustrations will be provided.