Mid-East crisis lends urgency to development of Water Fuel Cell - September 13th, 1990

By Marcia Thompson

September 13th, 1990

Source: https://grovecity.advantage-preservation.com/viewer/?k=&t=30203&i=t&d=01011901-12312011&m=between&ord=k1&fn=the_grove_city_record_usa_ohio_grove_city_19900913_english_1&df=11&dt=20

Stan Meyer, Grove City resident and inventor of the Water Fuel Cell technology which allows an engine to run on any type of water, has been preaching for the past ten years about a pending crisis in the Mid-East which will affect our use of oil as an energy source. That prediction seems more likely than ever to come true today as we follow the volatile events in the Mid-East which seem to change on an hourly basis.

“A Mid-East stalemate is possible, and the Water Fuel Cell technology could defuse the situation,” Meyer said. “It’s getting very exciting. We’re getting close. I’ve received calls from around the world, and now it’s time to show the world we have the technology.”

The energy crisis problem Meyer has warned about for the past ten years is nearing, he said, and events in the Gulf are bringing energy problems to the forefront.

Meyer, who works out of his lab in Grove City, said the fuel cell project he is working on now is moving towards production stage. He said that being blocked by the patent process has hindered the development, but he believes he is under the premise that they’d bring the technology out and get the unit into production, and that’s exactly what we plan to do as soon as possible.

When he says “we” he’s referring to himself, his twin brother, Steve Meyer of Florida, and other technicians who have been working on the project—including Ulf Dahlstrom and Mattias Johansson of Sweden, Charlie Holbrook of Washington, C.H., and Canadian aviation experts.

Meyer said that industry’s standard price tag to develop such a technology would be over $10.5 million just to develop the system concepts, and that doesn’t include the actual engineering designs. As much as $350 million could be needed to develop the overall technology.

“By keeping things simple and working out of a lab right here in Grove City, we’ve just taken the Water Fuel Cell technology further and further. It’s really coming together.”

Retrofit units can be put into existing vehicles or new ones, on planes or boats, to run home heating systems, and a myriad of other uses—all using water as a fuel source. The projected cost of a retrofit kit will be about $1,500.

“90% of the Water Fuel Cell is solid-state electronic design, and 10% of it is packaging using plastic mold injection technology,” said Meyer. “When mass production begins, we anticipate being able to produce 11,000 retrofit units every 24 hours.”

A 10-page article in Traum & zeit, U.S.A., Volume 1, No. 6, Feb-March, 1990, explains details about the Water Fuel Cell technology—how the Water Fuel Cell does not create energy but simply releases hydrogen that’s stored in water economically and controls the rate of its production on demand.

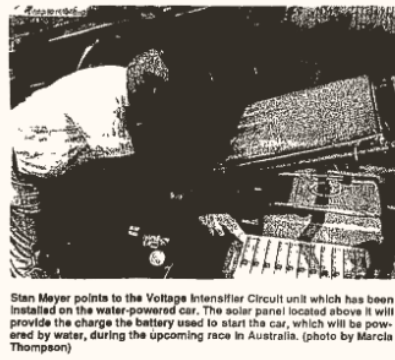

The Water Fuel Cell team of technicians is gearing up for a race to be held in Australia in November—a 1,900-mile race across the desert and through two mountain ranges. The race requires the use of solar power, so the dune buggy pre-engineering design vehicle has been equipped with a solar collector which will be used to charge the battery to start...

CAR: Water-powered car can help solve the problem of greenhouse effect

CAR: Water-powered car can help solve the problem of greenhouse effect

Water Fuel Cell technology to 176 nations at an international symposium. He spoke earlier this year at the S.A.F.E. Symposium in Einsiedeln, Switzerland, at an energy seminar where the Water Fuel Cell technology was presented to the scientific community. He’ll also be demonstrating the technology in England.

In addition to doing pre-engineering work on the Water Fuel Cell for cars, Meyer will also be working on a retrofit system for airplanes, jet aircraft, and diesel engines such as those that power boats.

“I wouldn’t be surprised to have an automobile delivered to me here in Grove City for a retrofit,” said Meyer.

The Water Fuel Cell may possibly be installed in an Alaskan Bushmaster plane built by Rick Schneider of Schneider Wheel Skies in Eagle River, Alaska. Schneider will be attempting to certify a rotary engine for virtually every general aviation aircraft. The plane has a simpler engine than current piston engines Schneider hopes to build and sell the engine at about half the price of conventional engines.

With the Water Fuel Cell installed on the plane, Schneider plans to attempt to break as many as 25 or 30 aviation records, including time aloft without refueling, distance flown without refueling, non-turbocharged altitude records, highest landing and take-off (near Mt. McKinley), and many others—all while being powered by water.

Stan Meyer continues to work around the clock to bring the Water Fuel Cell technology in, and WFC is receiving tremendous support from many countries, including England, Sweden, and Canada. “We’re getting international response to aid us in this stage of the development,” Meyer said.

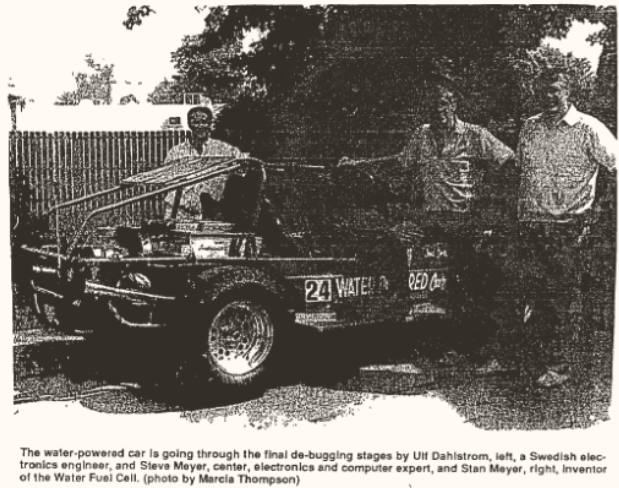

The water-powered car is going through the final de-bugging stages by Ulf Dahlstrom, left, a Swedish electronics engineer, and Steve Meyer, center, electronics and computer expert, and Stan Meyer, right, inventor of the Water Fuel Cell.

“If war in the Mid East cuts off oil supplies,” we’ll go into a "Manhattan-style" project in which all nations will come together under one roof and bring the technology to the marketplace, government, and military simultaneously,” Stan Meyer said.

“The demand for energy is paramount throughout the world,” he said. “It’s the number one problem. We’re working around the clock to bring the Water Fuel Cell technology in, and we’re receiving tremendous support from many countries, including England, Sweden, and Canada.”

The Water Fuel Cell Technology Center is in the planning stages for near Washington Court House, Ohio. “It will allow us to bring the nations of the world together under one roof and bring the technology to the marketplace, government, and military simultaneously,” Meyer said.

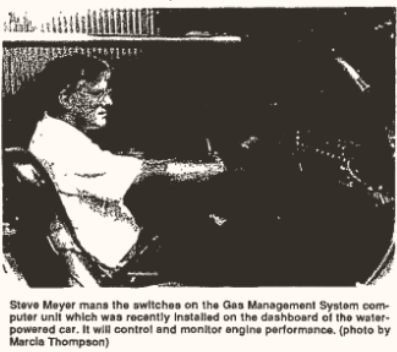

In anticipation of the event, the car has been completely redone—new steering, brakes, instrumentation, rewiring of the electrical system to new specifications—and the installation of some key components. The Hydrogen Gas Management system contains the GMS (Gas Management System), a computer unit that has been installed on the dashboard of the car. It will control and monitor the engine and engine performance and is one of the parts that will be completely miniaturized for the retrofit system.

In anticipation of the event, the car has been completely redone—new steering, brakes, instrumentation, rewiring of the electrical system to new specifications—and the installation of some key components. The Hydrogen Gas Management system contains the GMS (Gas Management System), a computer unit that has been installed on the dashboard of the car. It will control and monitor the engine and engine performance and is one of the parts that will be completely miniaturized for the retrofit system.

It is tied to the VIC (Voltage Intensifier Circuit) which has been updated for the third time and is currently being installed beside the water storage tank in front of the engine. This allows for the economical release of hydrogen from water and gives control on command.

“We’ve had to develop and invent everything we’ve done every step of the way,” said Meyer. “It’s all new technology.”

The dune buggy has a new engine, a standard 1600-series VW engine, which has had a laser distributor installed.

The two Meyer brothers will drive the car themselves during the six-day race in Australia.

“We, of course, want to prove the function and reliability of the engine,” said Stan Meyer. “We need to run the dune buggy under actual conditions such as temperature variances of extreme heat and cold and adverse weather conditions. However, we’re also running the race to win.”

From now to race time, a “de-bugging” process will be taking place. The last major patent, concerned with electrical patents, concerned with electrical patents, needed to be completed before the car was brought out to the public and was received in July. They are currently working on a systems approach patent which is now being filed and registered that covers the total process—“This needs to be done before we roll out the door,” said Steve Meyer. The dune buggy is an engineering unit, an on-wheels lab to monitor the performance of the car and the Water Fuel Cell. It is a prelude to the manufacturing of the retrofit kits.”

The retrofit energy system kits will have two major advantages—you don’t have to change an existing car or truck engine to install the Water Fuel Cell technology into it.

The retrofit energy system kits will have two major advantages—you don’t have to change an existing car or truck engine to install the Water Fuel Cell technology into it.

The retrofit kits will be put into existing vehicles or new ones, on planes or boats, to run home heating systems, and a myriad of other uses—all using water as a fuel source. The projected cost of the retrofit kit will be about $1,500. “90% of the Water Fuel Cell is solid-state electronic design, and 10% of it is packaging using plastic mold injection technology,” said Meyer. “When mass production begins, we anticipate being able to produce 11,000 retrofit units every 24 hours.”

He cited a 1989 article in Farmset-USA, Volume 1, No. 6, Feb.-March, 1990, explaining all about the Water Fuel Cell technology. “When mass production begins, the Water Fuel Cell adoption rate will skyrocket,” said Meyer.

In February 1991, Steve Meyer said, "I wouldn’t be surprised to have an automobile delivered to me here in Grove City for a retrofit. It’s an international project that we’re doing.”