Voltage Intensifier Circuit Explained

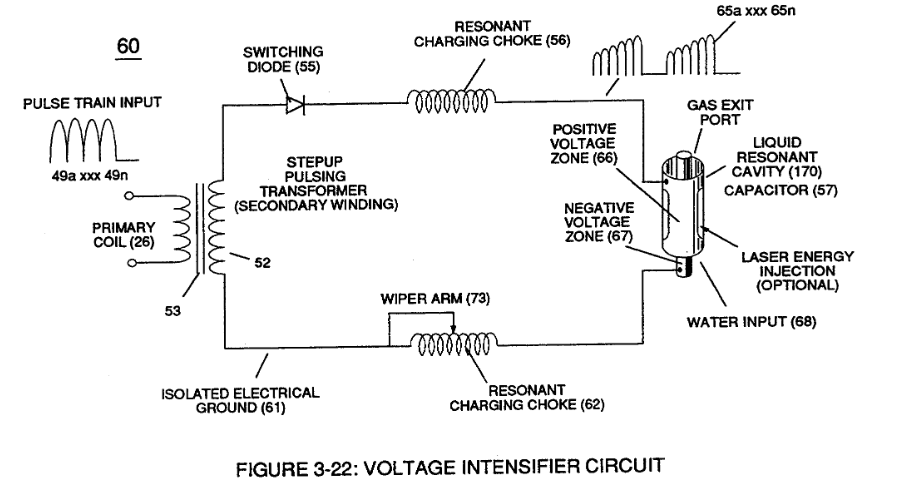

The Voltage Intensifier Circuit (VIC) is a crucial component of Stanley Meyer’s water fuel cell technology. It was designed to generate the high-voltage pulses needed to efficiently split water molecules into hydrogen and oxygen. The VIC's innovative design enabled Meyer to overcome the limitations of conventional electrolysis by focusing on high-voltage, low-current energy to achieve resonance and polarization in water molecules.

1. Purpose of the Voltage Intensifier Circuit

The main purpose of the Voltage Intensifier Circuit was to apply high-voltage electrical pulses to the water fuel cell, which would then induce resonance in the water molecules. Instead of using the conventional approach of applying a constant direct current (DC) to break the bonds between hydrogen and oxygen atoms, Meyer used the VIC to create an oscillating electric field that made it easier for these bonds to be broken. The goal was to reduce the amount of electrical energy required to dissociate the water molecules, thereby making hydrogen production more efficient.

2. Components of the Voltage Intensifier Circuit

The VIC is composed of several key components that work together to step up the voltage and generate the necessary pulses:

-

Step-Up Transformer: The step-up transformer is used to increase the voltage of the input signal. This high voltage is essential for creating the strong electric field needed to induce electrical polarization in the water molecules.

-

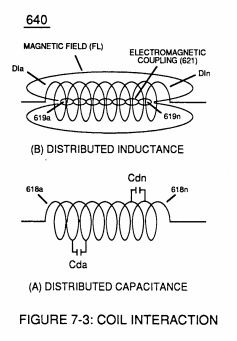

Choke Coils: The VIC also includes choke coils, which serve to limit the current flowing through the circuit. By limiting the current, Meyer aimed to avoid the high energy losses typically associated with conventional electrolysis, where significant amounts of power are wasted as heat. The choke coils help maintain the low-current, high-voltage conditions necessary for efficient operation.

-

Pulse Generator: The pulse generator is responsible for producing the high-frequency electrical pulses that are sent through the step-up transformer and into the water fuel cell. These pulses are designed to match the natural resonant frequency of the water molecules, creating a resonance effect that weakens the bonds between hydrogen and oxygen atoms.

3. How the Voltage Intensifier Circuit Works

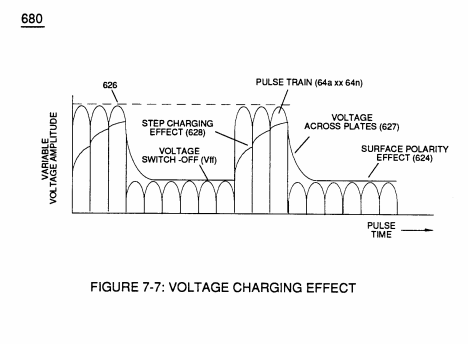

The Voltage Intensifier Circuit works by taking a low-voltage input and transforming it into a high-voltage output, which is then applied to the water fuel cell. The pulse generator sends a series of high-frequency electrical pulses through the step-up transformer, which increases the voltage to a level sufficient to create an electric field strong enough to polarize the water molecules. The choke coils ensure that the current remains low, preventing unnecessary power losses and maintaining the efficiency of the process.

The high-voltage pulses create an oscillating electric field that continuously polarizes and depolarizes the water molecules. This oscillation weakens the covalent bonds between the hydrogen and oxygen atoms, making it easier to split the water molecules and release hydrogen and oxygen gases. By carefully tuning the frequency of the pulses to match the natural frequency of the water molecules, Meyer aimed to achieve a resonance effect that would further enhance the efficiency of the dissociation process.

4. Advantages of the Voltage Intensifier Circuit

The VIC offered several advantages over traditional methods of electrolysis:

-

Energy Efficiency: By using high-voltage pulses and limiting the current, the VIC aimed to reduce the overall energy consumption required to produce hydrogen. This was a significant improvement over conventional electrolysis, which requires a continuous supply of electrical energy.

-

On-Demand Hydrogen Production: The use of high-voltage pulses allowed for the production of hydrogen on-demand, without the need for large storage tanks or complex infrastructure. This made Meyer’s water fuel cell technology more practical for a wide range of applications.

-

Reduced Heat Loss: Traditional electrolysis often results in significant heat loss due to the high current required. The VIC’s design, which prioritized high voltage and low current, helped to minimize these losses and improve the overall efficiency of the process.

The Voltage Intensifier Circuit was a key innovation in Stanley Meyer’s water fuel cell technology, enabling the use of high-voltage pulses to efficiently split water molecules. By focusing on voltage rather than current, and by using resonance to enhance the dissociation process, the VIC represented a major departure from traditional electrolysis methods. This approach, if proven effective, could pave the way for a more efficient and sustainable means of hydrogen production, offering a clean alternative to fossil fuels.