Gas Modulator Process

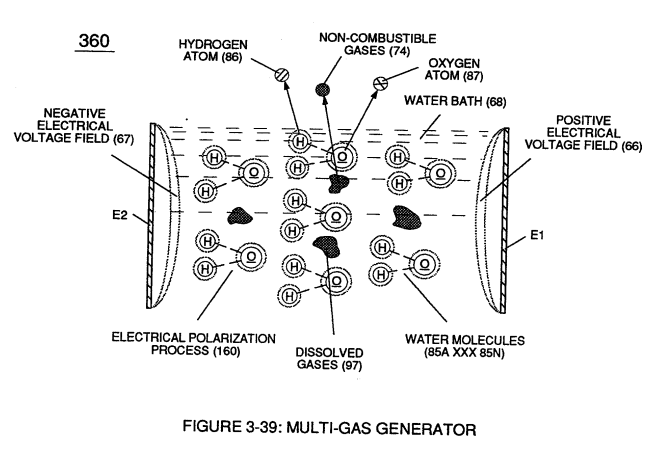

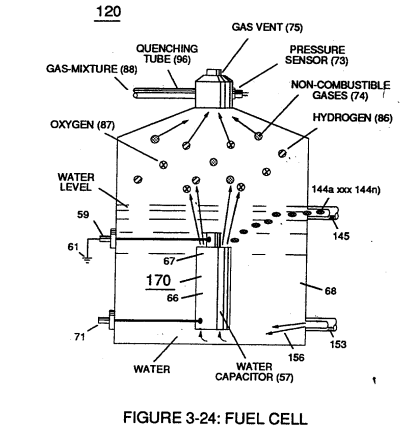

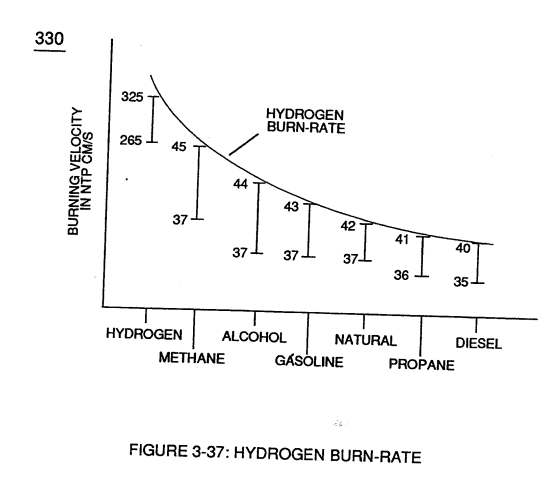

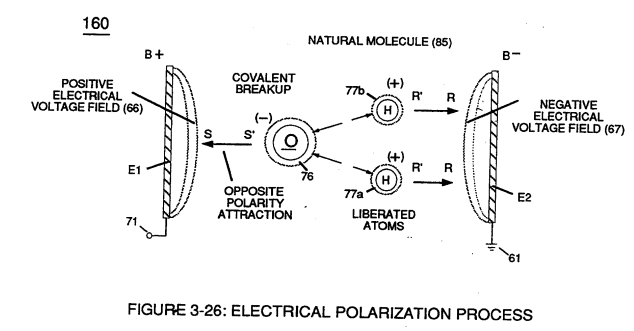

Dissolved air gases (97) of Figure (3-39) being uniformly released from water bath (85) via the Electrical Polarization Process (160) of Figure (3-26) is automatically intermixed with released hydrogen (86) and oxygen (87) gas atoms (also derived from water bath 85) to form Fuel-Gas mixture (88) of Figure (3-24) having a hydrogen gas burn-rate of approximately 47 centimeters per seconds (cm/see) in ambient air, as illustrated in (330) of Figure (3-37).

|

Dissolved air gases (97) of Figure (3-39) |

Electrical Polarization Process (160) of Figure (3-26) |

|

Fuel-Gas mixture (88) of Figure (3-24) |

(330) of Figure (3-37) |

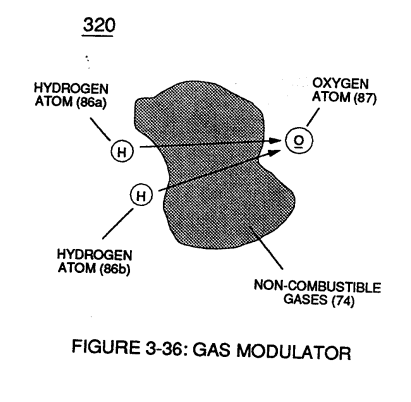

Volatility of hydrogen fuel-mixture or Fuel-Gas (88) is reduced from 325 cm/sec. to approximately 47 cm/sec. since ambient air gases (97) (dissolved air gases in water) is primarily composed of non-combustible gases (74) (such as nitrogen, argon, and other non-burnable gases) of Figure (3-39) which acts and performs as a "Gas Modulator" during thermal gas ignition (98), as illustrated in (320) of Figure (3-36).

|

(320) of Figure (3-36) |

Figure (3-39) |

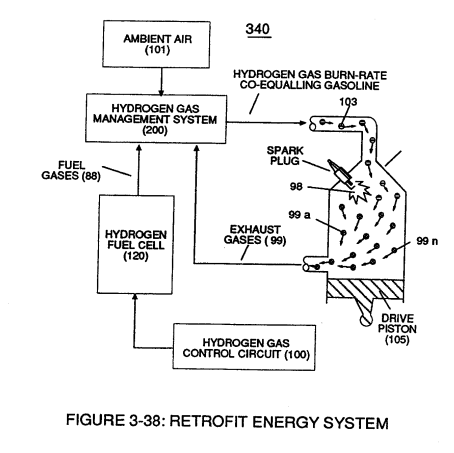

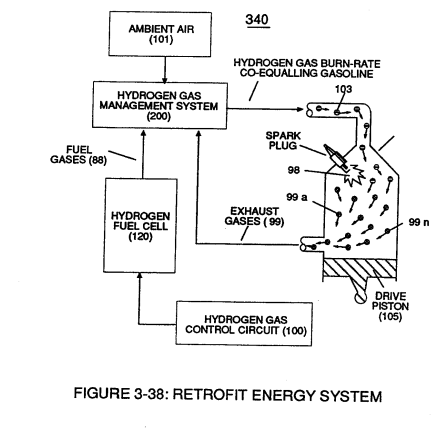

The non-combustible gases (74) physically retards and slows down the speed by which oxygen atom (87) unites with (covalent link up) hydrogen atoms (86a / 86b) to bring on and support gas ignition process (gas combustion process) (98), as further illustrated in (340) of Figure (3-38).

|

(340) of Figure (3-38) |

Figure (3-24) |

Water bath (68) of Figure (3-39) as to Figure (3-24), now, becomes and functions as a "Gas Mixing Regulator" since the highest possible thermal explosive energy yield (gtnt) obtainable from hydrogen during "normal" gas ignition (98) is the exact composition of water where two hydrogen atoms (86a / 86b) unite with oxygen atom (87).

Inherently, the utilization of the Electrical Polarization Process (160) of Figure (3-26) in conjunction with the use of chemically inert stainless steel (T304 material) voltage zones (E1 / E2) submerged in natural water (68) sustains and maintains gas mixing ratio (88) by simply preventing the consumption of both the hydrogen (86) and oxygen (87) gases by way of not encouraging

Inherently, the utilization of the Electrical Polarization Process (160) of Figure (3-26) in conjunction with the use of chemically inert stainless steel (T304 material) voltage zones (E1 / E2) submerged in natural water (68) sustains and maintains gas mixing ratio (88) by simply preventing the consumption of both the hydrogen (86) and oxygen (87) gases by way of not encouraging

"electrical heat" or "chemical interaction" associated with amp consumption.

Remember, Electrical Polarization Process (160) is a physical process which uses opposite electrical polarity attraction force (qq') to perform work by disrupting and switching off the covalent bond between the unlike charged water molecule atoms.

To further reduce hydrogen burn-rate (330) of Figure (3-37) to other fossil-fuel burning levels, additional non-combustible gases (99a xxx 99n) (supplied via ambient air 101) is added to gas-mixture (88) by way of gas ignition process (98) occurring inside internal combustion engine (55) piston cylinder (102), as illustrated in (340) of Figure (3-38).

|

hydrogen burn-rate (330) of Figure (3-37) |

(340) of Figure (3-38) |

As fuel-gas (88) enters into engine cylinder (102) and is exposed to thermal gas ignition process (98), the incoming and moving fuel-gases (88) are converted into non-combustible gases (99) (gases passing through the gas combustion process) since both the hydrogen (86) and oxygen (87) gas atoms are being consumed during the formation of superheated water mist (103)

... releasing thermal explosive energy (gtnt) which, in turns, causes piston-action to expel the newly formed non-combustible exhaust gases (99) for recycling.

The liberated and cooled exhaust gases (99) is, now, directed to hydrogen injector system (200) which systematically meter-mixes and superimposes a predetermined amount of non-burnable gases (99) of Figure (3-38) onto incoming ambient air gases (101) which is being directed to engine cylinder (102) to sustain and maintain both the "Gas Modulator Process" (320) of Figure (3-36) and the "Gas Ignition Process" (98), simultaneously.

|

"Gas Modulator Process" (320) of Figure (3-36) |

(340) of Figure (3-38) |

In essence, then, ambient air gases (101) becomes an endless supply of non-combustible gases (99A xxx 99n) during the gas ignition process.

The resultant and on-going Gas Modulator Process (320) of Figure (3-36), now, allows hydrogen fuel cell (120) of Figure (3-24) to be retrofitted to any conventional internal combustion engine (55) of Figure (3-1) without engine change by simply metering the proper amount of exhaust gases (99a xxx 99n) to comply with and co-equaling any type or different fossil-fuel burning levels, as further illustrated in (330) of Figure (3-37).

|

Fuel-Gas mixture (88) of Figure (3-24) |

(330) of Figure (3-37) |

In terms of operability and performance, gas modulator process (320) continues to allow a conventional internal combustion engine (55) to run on ambient air gases; while, fuel-gas (88) not only cuts back and reduces oxygen extraction form ambient air (101) but produces a environmentally safe exhaust gases since non-combustible gases (99/74) from both ambient air gases (101) and Fuel-Gas (88) are thermally inert to gas ignition process (98).